One-Stop Multilayer PCB Manufacturing (3 to 64 Layers)

A multilayer PCB consists of more than two copper layers. It helps save space while enhancing circuit density, with the ability to support up to 64 layers.

What is Multilayer PCB?

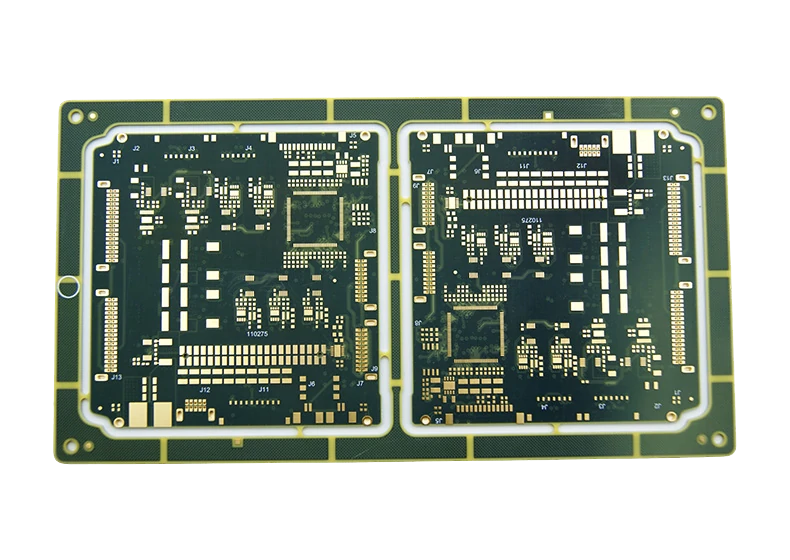

Multilayer PCBs feature three or more copper layers and are commonly used for high-density applications. The core materials can include FR4, aluminum, copper, PI, PET, PTFE, and ceramics, with components mounted on one or both sides.

Mars PCB manufactures various types of multilayer PCBs, including FR4, flexible, rigid-flex, ceramic, and high-frequency PCBs. We also produce HDI PCBs and high-performance circuit boards for industries like communications, medical, automotive, and industrial applications.

- Higher Circuit Density

- Smaller Product Sizes

- Flexible Circuit Design

- Reduced EMI (Electromagnetic Interference)

Multilayer PCB Manufacturing Process

The manufacturing workflow for multilayer PCBs includes these steps:

- Cutting laminate

- Generating inner circuit layers

- Lamination

- Drilling

- Copper plating

- Outer layer circuit generation

- Automatic optical inspection (AOI)

- Solder mask and silkscreen

- Surface finish

- Electrical testing

- Final quality check

- Packaging and delivery

In the lamination process, care is taken to avoid air pockets, ensuring that the resin bonds the conductive layers securely.

PCB Layer Options for Multilayer PCBs

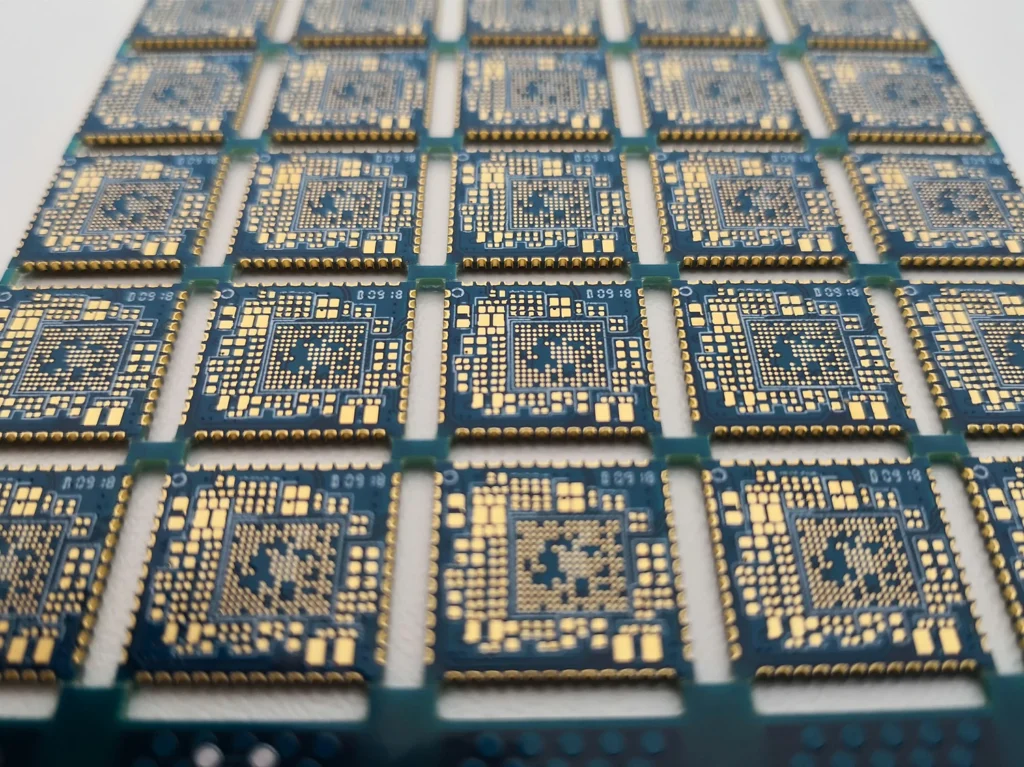

Mars PCB can produce and assemble multilayer PCBs with up to 64 layers. Some of the most common configurations include:

Mars PCB can produce and assemble multilayer PCBs with up to 64 layers. Some of the most common configurations include:

- FR4 Multilayer PCB: 4-layer, 6-layer, 8-layer, 10-layer, 12-layer, 16-layer, up to 64 layers

- Ceramic Multilayer PCB: 4-layer

- Rigid-Flex PCB: 3-layer, 4-layer, 6-layer, 8-layer, 10-layer, up to 24 layers

- Flexible PCB: 4-layer, 6-layer, 8-layer

- High-Frequency PCB: 4-layer, 6-layer, 8-layer, up to 24 layers

Mars PCB Multilayer PCB Capabilities

Specifications | Mars PCB’s Multilayer PCB Capabilities |

PCB Layers | 3 to 108 |

Build Time | 2 day to 4 weeks |

Finished PCB Thickness | 0.15mm to 12mm |

Materials | FR4, PTFE, PI, Aluminum, Copper, Ceramics |

Copper Thickness | 1/3oz to 7oz |

Tg (FR4 Multilayer PCB) | 135°C to 240°C |

Min. Drill Bit Size | 8mil |

Min. Trace Space/Width | 2.5mil (inner), 2.5mil (external) |

PCB Assembly Min. Pitch | 0.35mm |

HDI Stack-Up | 1+N+1, 2+N+2, 3+N+3, 4+N+4 |

Aspect Ratio | 3:4 (laser drill), 10:1 (PTH) |

Surface Finish | HASL, ENIG, Immersion Tin, Immersion Silver, Hard Gold, Peelable Mask, Carbon Ink |

Why Choose Mars PCB for Multilayer PCBs?

Mars PCB offers high-quality materials for multilayer PCBs, including FR4, rigid-flex, flexible, aluminum, copper, and ceramic. For FR4 boards, we use high-Tg material to ensure durability and performance.

Mars PCB has specialized production lines, including advanced immersion gold technology, providing industry-leading capabilities in multilayer PCB manufacturing.

Our experienced engineers can optimize your multilayer PCB design and provide personalized support to meet your specific needs, ensuring a smooth production process from start to finish.

Mars PCB follows a rigorous ISO-based quality management system. Our multilayer PCBs are certified to ISO 9001, IATF 16949, RoHS, REACH, UL, and IPC standards, guaranteeing the highest quality and reliability.

Mars PCB provides end-to-end services, from PCB design and prototyping to assembly, testing, and delivery. We offer flexible, customized solutions based on your project requirements.

Mars PCB offers a range of shipping options, including air, sea, and rail services through trusted carriers like DHL, FedEx, and UPS. We also allow you to choose your preferred freight forwarder.

Certifications

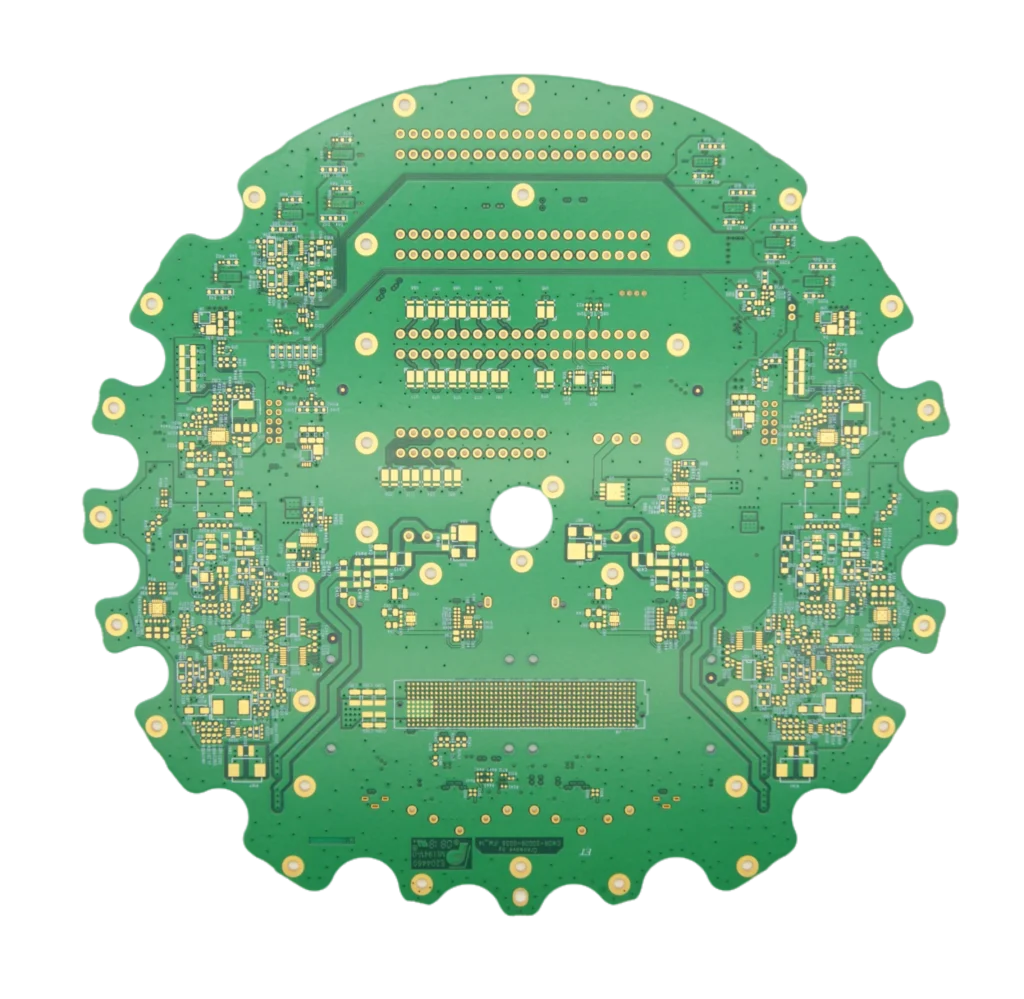

Real-World Examples

Mars PCB recently produced a 12-layer PCB for a client in the automotive sector. The precise control of PAD tolerance ensured the integrity of the solder mask bridges, demonstrating our attention to detail and high manufacturing standards.

Contact Mars PCB's Expert Team Today

For more information or to request a quote, get in touch with our team today!