When comparing the durability of Multilayer PCBs vs. Flexible Printed Circuits, the winner depends entirely on the application. Flexible circuits excel in environments with constant bending, vibration, and tight space constraints due to their inherent pliability. In contrast, rigid multilayer PCBs offer superior structural integrity and resistance to direct impact and punctures. The choice is less about which is inherently ‘stronger’ and more about matching the board’s properties to the specific mechanical and environmental stresses it will face throughout its lifecycle.

Table of Contents

- Understanding the Core Durability Question

- What is a Multilayer PCB?

- What is a Flexible Printed Circuit (FPC)?

- Head-to-Head Durability Showdown: A Situational Analysis

- Comparative Analysis: Multilayer PCB vs. FPC at a Glance

- When Should You Choose a Multilayer PCB?

- When is a Flexible Circuit the Right Choice?

- The Best of Both Worlds: What About Rigid-Flex PCBs?

- Conclusion: Defining Durability for Your Application

Understanding the Core Durability Question

In the world of electronics design, “durability” is not a monolithic concept. It is a multifaceted property that describes how a printed circuit board withstands various stressors. When engineers ask, “Which is more durable?”, they are really asking a series of more specific questions: Which can bend more? Which can better survive a drop? Which can handle constant shaking? To make an informed decision between a multilayer rigid board and a flexible circuit, one must first deconstruct the term “durability” into its key components and analyze the unique demands of the product’s intended environment. This granular approach prevents costly design errors and ensures long-term product reliability.

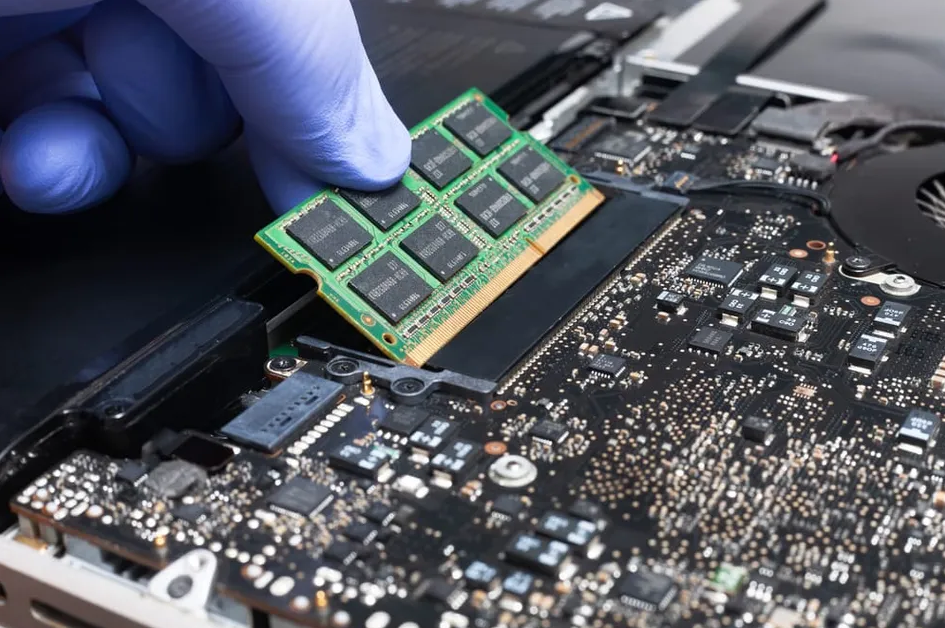

What is a Multilayer PCB?

A multilayer PCB is a printed circuit board that consists of three or more conductive copper layers laminated together with insulating material. These boards are the backbone of most complex electronics, from motherboards to servers. Their rigid structure is created by pressing together alternating layers of prepreg (a fiberglass cloth pre-impregnated with epoxy resin) and copper foil under high temperature and pressure. This process creates a single, solid, and non-pliable board that provides excellent structural support for components.

Construction and Materials

The defining characteristic of a multilayer PCB is its rigid substrate. The most common material used is FR-4 (Flame Retardant 4), a glass-reinforced epoxy laminate. This material provides a stable and robust platform for mounting and soldering components. The layers are interconnected using “vias”—plated holes that allow electrical signals to pass vertically through the board. This layered design enables incredibly dense and complex circuit routing that would be impossible on a single or double-sided board, making it ideal for high-performance applications.

Inherent Strengths and Weaknesses

The primary strength of a multilayer PCB is its mechanical rigidity. It serves not only as an electrical interconnect but also as a structural element of the final product. This rigidity protects delicate surface-mount components from physical stress and provides a stable thermal mass for heat dissipation. However, this same rigidity is its greatest weakness in applications requiring movement. Any attempt to bend or flex a multilayer PCB will cause micro-fractures in the copper traces or delamination between layers, leading to immediate and catastrophic failure.

What is a Flexible Printed Circuit (FPC)?

A Flexible Printed Circuit, often called a flex circuit or FPC, is a patterned arrangement of conductive traces on a flexible substrate. Unlike their rigid counterparts, FPCs are designed to bend, twist, and fold to fit into compact and uniquely shaped electronic assemblies. They effectively replace traditional wiring harnesses, connectors, and rigid boards, leading to significant reductions in weight, size, and assembly complexity. This adaptability has made them indispensable in modern electronics like wearables, cameras, and automotive systems.

Construction and Materials

The key to an FPC’s flexibility lies in its base material. Instead of FR-4, flex circuits are typically built on a substrate of Polyimide (PI), a polymer known for its remarkable flexibility, thermal stability, and chemical resistance. Thin, rolled-annealed copper foil is bonded to the polyimide film, and a thin coverlay (also typically polyimide) is applied to insulate and protect the circuitry. This construction creates a thin, lightweight, and incredibly pliable circuit that can conform to virtually any shape.

Inherent Strengths and Weaknesses

An FPC’s defining advantage is its dynamic flex endurance. It can be bent and folded thousands or even millions of times without electrical failure, a feat impossible for a rigid board. This makes it perfect for applications with moving parts, such as in laptop hinges or printer heads. Flex circuits are also inherently more resistant to vibration and shock. Their low mass and ability to ‘give’ allows them to absorb mechanical energy that would otherwise crack solder joints on a rigid board. Their main weakness is a lack of structural support and a higher susceptibility to tearing or punctures compared to a thick FR-4 board.

Head-to-Head Durability Showdown: A Situational Analysis

To truly determine which PCB type is more durable, we must compare them across different stress categories. The winner in one scenario is often the loser in another, highlighting the importance of matching the board to the specific application challenges.

Flexibility and Bending Cycles: Where FPCs Reign Supreme

This is the most straightforward comparison. Flexible circuits are explicitly designed for bending. A well-designed FPC using rolled-annealed copper can withstand tens of thousands of dynamic flex cycles without any degradation in performance. Multilayer rigid PCBs, on the other hand, have virtually zero tolerance for bending. A single forceful flex can permanently damage the board, breaking traces and lifting pads. For any application requiring movement, from a simple one-time “flex-to-install” to continuous dynamic flexing, the FPC is the only durable option.

Winner: Flexible Printed Circuit

Vibration and Shock Resistance: The Surprising Resilience of Flex

In high-vibration environments such as automotive, aerospace, or industrial machinery, the mass and stiffness of a multilayer PCB can be a liability. Vibrations can cause component leads and solder joints to fatigue and crack over time. Flexible circuits, being lighter and more compliant, are far more resilient. They can absorb and dampen vibrational energy, reducing the stress transferred to solder connections. This inherent damping quality makes FPCs a more durable choice for applications where constant shaking and mechanical shock are expected.

Winner: Flexible Printed Circuit

Impact and Puncture Resistance: The Advantage of Rigidity

When it comes to resisting a direct physical impact or a sharp puncture, the thick, hard structure of a multilayer PCB provides superior protection. The FR-4 substrate acts as a shield, distributing the force of an impact and protecting the inner copper layers and mounted components. A thin polyimide FPC, while flexible, is much more susceptible to being torn or punctured by a sharp object. In devices that may be dropped or subjected to rough handling, the structural robustness of a multilayer board offers greater durability.

Winner: Multilayer PCB

Thermal Stress and Heat Dissipation: A Complex Comparison

Thermal durability is a nuanced topic. Multilayer PCBs with multiple thick copper ground and power planes can act as excellent heat sinks, efficiently pulling heat away from high-power components. However, the difference in the Coefficient of Thermal Expansion (CTE) between FR-4 and copper can induce stress during thermal cycling, potentially leading to via fatigue. Polyimide, the base for FPCs, has a higher temperature rating and a CTE closer to copper, reducing stress. Yet, the thinness of an FPC makes it a poor heat dissipator on its own, often requiring additional thermal management solutions like stiffeners or heat sinks. The choice depends on whether the primary challenge is high ambient temperature or dissipating focused heat from a component.

Winner: Application Dependent

Environmental Durability: Moisture and Chemical Resistance

Both PCB types can be designed for harsh environments. Polyimide is naturally more resistant to chemicals and has lower moisture absorption than standard FR-4. The seamless polyimide coverlay on an FPC provides excellent protection against moisture ingress. However, multilayer PCBs can be enhanced with conformal coatings that provide a robust barrier against humidity, dust, and corrosive chemicals. While FPCs have a slight material advantage, proper design and protective coatings can make both options highly durable against environmental factors.

Winner: Slight edge to Flexible Printed Circuits (material), but both can be robust.

Comparative Analysis: Multilayer PCB vs. FPC at a Glance

This table provides a quick summary of the key durability and design characteristics for each board type.

| Feature | Multilayer PCB | Flexible Printed Circuit (FPC) |

|---|---|---|

| Dynamic Flex Endurance | Very Poor (Fails after few bends) | Excellent (Thousands to millions of cycles) |

| Vibration Resistance | Good (Susceptible to solder joint fatigue) | Excellent (Absorbs and dampens vibrations) |

| Impact & Puncture Resistance | Excellent (Rigid structure provides protection) | Fair (Thin material can be torn or punctured) |

| Structural Support | Excellent (Acts as a structural component) | Poor (Requires mechanical support) |

| Space & Weight | Fair (Bulkier and heavier) | Excellent (Extremely lightweight and space-saving) |

| Thermal Management | Good (Thick copper planes act as heat sinks) | Fair (Requires stiffeners or external heat sinks) |

When Should You Choose a Multilayer PCB?

A multilayer PCB is the right choice when structural integrity and high-density component mounting are the top priorities. If your device will not experience any bending or significant vibration, and requires a solid, stable foundation for its electronics, a multilayer board is the more durable and cost-effective solution.

Ideal Applications:

- Computer Motherboards and Server Racks

- Power Supplies and Industrial Controllers

- Desktop and Stationary Consumer Electronics

- High-speed Digital and RF Modules

When is a Flexible Circuit the Right Choice?

A flexible circuit is the superior choice for durability in any application that involves motion, vibration, or severe space and weight constraints. When the product must bend, fold, or withstand constant shaking, an FPC is not just an option—it is a necessity for long-term reliability.

Ideal Applications:

- Wearable Devices and Medical Implants

- Digital Cameras and Mobile Phones (e.g., hinge connections)

- Automotive Electronics (e.g., in steering columns, door panels)

- Aerospace and Military Systems

The Best of Both Worlds: What About Rigid-Flex PCBs?

For the most demanding applications, a third option exists: the rigid-flex PCB. This hybrid technology combines the best of both worlds by integrating flexible circuit sections with rigid multilayer sections into a single, unified board. This allows designers to mount dense components on the rigid parts while using the integrated flexible sections to connect between them, eliminating failure-prone cables and connectors. Rigid-flex PCBs offer the ultimate in mechanical durability and reliability, especially in aerospace and medical applications, though they come at a significantly higher cost.

Conclusion: Defining Durability for Your Application

Returning to our original question—Multilayer PCB vs. Flexible Printed Circuit: Which is more durable?—the definitive answer is clear: the most durable PCB is the one best suited to its environment. There is no universal winner. A multilayer board is incredibly durable in a static, high-impact environment, while a flexible circuit is far more robust in a dynamic, high-vibration setting. A successful and reliable product design hinges on a thorough analysis of the mechanical and environmental stresses it will endure. By understanding the inherent strengths and weaknesses of each technology, you can select a PCB solution that delivers true durability where it matters most for your specific application.

Multilayer PCB vs Flexible Printed Circuit, PCB durability, flexible circuit mechanical stress, FPC vibration resistance, rigid PCB impact resistance, what is a flexible printed circuit, when to use multilayer pcb, durability of FPC vs rigid pcb