When selecting a printed circuit board (PCB) for your electronics project, the choice between a Multilayer PCB and a Rigid-Flex PCB is a critical decision point. A Multilayer PCB is a cost-effective and powerful solution for complex electronics housed in static, fixed enclosures, offering high component density on a solid board. In contrast, a Rigid-Flex PCB provides unparalleled design freedom, durability, and space-saving benefits for applications requiring three-dimensional assembly, dynamic flexing, or extreme reliability, albeit at a higher initial fabrication cost. The best choice ultimately hinges on a careful analysis of your application’s specific requirements, including budget, space constraints, mechanical stress, and long-term reliability goals.

Table of Contents

- Understanding the Fundamentals: What is a Multilayer PCB?

- Exploring Innovation: What is a Rigid-Flex PCB?

- Head-to-Head Comparison: Multilayer vs. Rigid-Flex PCB

- Making the Right Choice: Key Questions to Ask for Your Application

- Real-World Applications: Where Each PCB Type Shines

- Conclusion: Matching the PCB to Your Project’s DNA

- Frequently Asked Questions (FAQ)

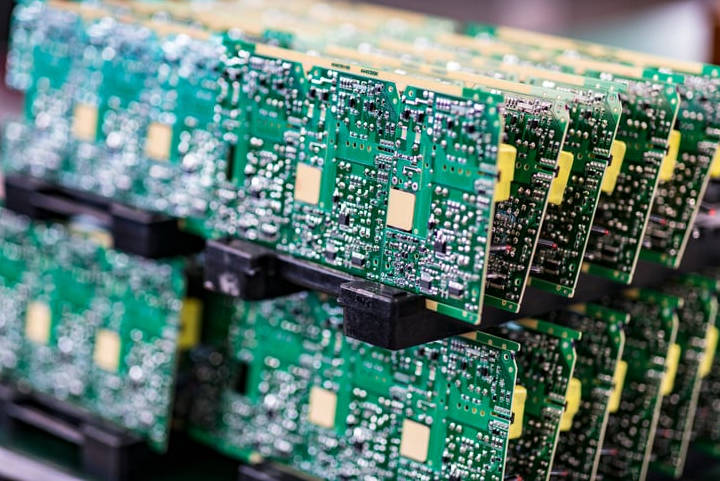

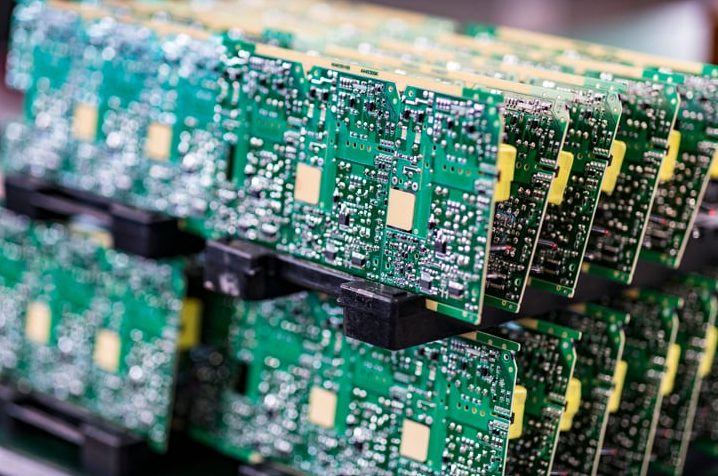

Understanding the Fundamentals: What is a Multilayer PCB?

A Multilayer PCB is a printed circuit board that consists of three or more conductive copper layers laminated together with layers of insulating material. These boards are the backbone of modern electronics, providing a compact and highly interconnected platform for complex circuits. Unlike a simple single or double-sided board, the inner layers allow for a massive increase in routing density, making them essential for devices where space is a consideration but the form factor is generally static.

The Layered Construction of Multilayer PCBs

The construction of a multilayer board involves a “sandwich” of materials. It starts with a central core, which is typically a double-sided PCB made of a rigid substrate like FR-4 (Flame Retardant 4). Additional layers of pre-impregnated glass fiber (prepreg) and copper foil are then stacked on either side of this core. The entire stack is subjected to intense pressure and heat in a lamination press, which bonds the layers together into a single, solid board. Vias—drilled and plated holes—are used to create electrical connections between the different layers, allowing for a complex web of traces to be routed in a three-dimensional space within the board itself.

Key Advantages of Multilayer PCBs

The primary advantage of multilayer PCBs is their ability to support incredibly high component density. By routing signals on internal layers, designers can free up surface space for more components, creating powerful devices in a smaller footprint than would be possible with single-sided boards. This layered structure also offers superior electrical performance, as dedicated ground and power planes can be incorporated to improve signal integrity and reduce electromagnetic interference (EMI). Furthermore, the manufacturing process for multilayer boards is highly mature and standardized, making them a very cost-effective solution for mass production.

Common Limitations and Disadvantages

The most significant limitation of a multilayer PCB is its inherent rigidity. The entire board is a single, inflexible unit, which means it cannot be bent or folded to fit into unconventional or tight spaces. This necessitates the use of connectors, cables, and wires to link separate boards within a product enclosure, which can introduce potential points of failure, increase assembly time, and add to the overall weight and bulk of the final product. Additionally, once laminated, the internal layers are inaccessible, making repairs and modifications nearly impossible.

Exploring Innovation: What is a Rigid-Flex PCB?

A Rigid-Flex PCB is a hybrid circuit board that combines elements from both rigid boards and flexible circuits. These boards feature rigid sections, typically made from FR-4, where components are mounted, interconnected by flexible sections made from a pliable substrate like polyimide. This innovative construction allows the board to be bent, folded, and twisted to fit complex, three-dimensional product enclosures, eliminating the need for traditional connectors and cables while maintaining the high component density of a rigid board.

The Hybrid Structure of Rigid-Flex PCBs

The magic of a rigid-flex PCB lies in its selective integration of materials. The flexible layers, made of thin, resilient polyimide, run continuously throughout the entire board structure. In the rigid sections, multiple layers of FR-4 and prepreg are laminated onto these flexible layers to create a stable mounting surface for components. The transition between rigid and flex is carefully engineered to ensure durability. This creates a single, unified electronic interconnect solution that can be manipulated during assembly and, in some cases, can be designed for *dynamic flexing* during the product’s operational life.

Unpacking the Advantages of Rigid-Flex

The benefits of rigid-flex technology are substantial. The most obvious is design freedom; engineers are no longer constrained by flat, two-dimensional planes. This leads to smaller, lighter, and more ergonomically shaped products. Reliability is another key advantage. By replacing connectors, ribbon cables, and solder joints—common points of failure—with integrated flexible circuits, the overall system becomes more robust and resistant to shock and vibration. The streamlined design also simplifies the assembly process, reducing parts count and potential for human error.

The Challenges and Considerations

The primary barrier to adopting rigid-flex PCBs is their cost. The specialized materials, complex manufacturing processes (including multiple lamination cycles), and lower production yields result in a significantly higher per-unit fabrication cost compared to traditional multilayer boards. The design process is also more complex, requiring sophisticated EDA (Electronic Design Automation) software and careful consideration of mechanical factors like bend radius and stiffeners to ensure the board’s long-term integrity.

Head-to-Head Comparison: Multilayer vs. Rigid-Flex PCB

Choosing between these two technologies requires a direct comparison across several key metrics. While both can host complex circuits, their fundamental differences in construction lead to vastly different performance characteristics, costs, and ideal use cases.

| Attribute | Multilayer PCB | Rigid-Flex PCB |

|---|---|---|

| Fabrication Cost | Lower | Higher (3-7x) |

| Flexibility | None (Completely Rigid) | High (Can be bent and folded) |

| Reliability | Good, but dependent on connectors/cables | Excellent (Fewer interconnects, high shock/vibration resistance) |

| Size & Weight | Larger and heavier system due to need for interconnects | Smaller and lighter system by eliminating connectors |

| 3D Design Capability | Limited (Requires multiple boards and cables) | Inherent (Designed for 3D enclosures) |

| Assembly Complexity | Higher (Requires manual assembly of cables/connectors) | Lower (Single-piece installation) |

| Design Complexity | Moderate | High |

Cost Analysis: Upfront Fabrication vs. Total Cost of Ownership

On a per-board basis, a rigid-flex PCB is always more expensive to manufacture than a multilayer PCB of similar complexity. However, this only tells part of the story. It’s crucial to consider the Total Cost of Ownership (TCO). A system built with multilayer boards may require purchasing multiple PCBs, connectors, wiring harnesses, and the labor costs associated with assembling them all. When these ancillary costs are factored in, a rigid-flex solution, which integrates all these elements into one part, can become cost-competitive or even cheaper, especially when considering the reduced assembly time and improved yield from eliminating potential connection errors.

Mechanical Properties: Flexibility and Durability

This is where rigid-flex PCBs truly excel. Their ability to bend and fold is their defining feature. This makes them ideal for applications subjected to high vibration or shock, as the flexible sections can absorb mechanical stress that would crack a rigid board or dislodge a connector. The continuous connections within a rigid-flex board are far more durable than the discrete solder joints and crimped pins of a cable assembly, significantly enhancing the product’s long-term reliability in harsh environments.

Design and Form Factor: Space, Weight, and 3D Integration

For modern compact devices like wearables, medical implants, and advanced military hardware, space and weight are at a premium. Rigid-flex technology enables “3D packaging,” where the circuit can be folded to conform to the contours of the product’s chassis. This eliminates wasted space, reduces the overall weight by removing bulky connectors and wires, and allows for more streamlined and innovative product designs that would be impossible with flat, rigid boards.

Assembly and Reliability: The Role of Connectors

Connectors are a necessary evil in many electronic systems. They are a primary source of failure due to issues like intermittent connections, contact fretting from vibration, or incorrect mating during assembly. Rigid-flex PCBs largely eliminate this failure point. The entire circuit is a single, integrated piece, which simplifies the bill of materials (BOM), streamlines the assembly line, reduces the chance of assembly errors, and leads to a more robust and reliable final product.

Electrical Performance and Signal Integrity

Both board types can be designed for excellent electrical performance. Multilayer PCBs offer well-controlled impedance through the use of ground and power planes. Rigid-flex PCBs maintain these benefits in their rigid sections. In the flexible sections, careful design is required to manage impedance and signal integrity, but the elimination of connectors—which can introduce impedance discontinuities and signal degradation—can often result in superior overall system performance, particularly for high-speed signals.

Making the Right Choice: Key Questions to Ask for Your Application

To determine which PCB is best for you, move beyond the spec sheets and ask practical questions about your project’s goals and constraints.

What Are Your Space and Weight Constraints?

If your device must fit into a tight, irregularly shaped enclosure, or if minimizing weight is a top priority (e.g., in aerospace, drones, or wearable tech), the advantages of a rigid-flex PCB are compelling. Its ability to fold and conform to the product’s shape makes it the superior choice for miniaturization. If your product has a standard boxy enclosure with ample space, a multilayer PCB is likely the more economical and practical option.

Does Your Application Involve Vibration, Shock, or Bending?

For any product that will be dropped, moved, or exposed to significant vibration (e.g., automotive electronics, industrial machinery, military equipment), reliability is paramount. The inherent durability of the integrated connections in a rigid-flex PCB makes it far more resilient than a system of rigid boards linked by connectors. If your device will remain stationary in a controlled environment, such as a server or desktop computer, a multilayer PCB provides sufficient durability.

What is Your Project Budget and Production Volume?

If upfront cost is the primary driver and you are producing in high volumes, the mature manufacturing processes of multilayer PCBs offer an undeniable economic advantage. For prototypes or low-volume runs where the per-unit cost difference is less impactful, a rigid-flex board might be justifiable. However, remember to calculate the TCO. If the assembly savings and reliability gains of a rigid-flex PCB offset its higher fabrication cost over the product’s lifecycle, it can be the wiser long-term investment.

How Complex is Your Assembly Process?

Consider your manufacturing capabilities. A system requiring multiple multilayer boards connected by a complex wiring harness can lead to high labor costs and a greater potential for errors. A rigid-flex PCB simplifies this dramatically by arriving as a single, pre-tested component. This can accelerate production, reduce rework, and improve final product quality, making it an attractive option for complex assemblies.

Real-World Applications: Where Each PCB Type Shines

Typical Use Cases for Multilayer PCBs

Thanks to their balance of performance and cost, multilayer boards are ubiquitous in the electronics industry. You will find them in:

- Computer Systems: Motherboards, servers, and data storage devices where high-density routing is needed in a standard form factor.

- Consumer Electronics: Televisions, gaming consoles, and home appliances that have fixed internal structures.

- Industrial Controls: Power supplies and control systems that are housed in protective, static enclosures.

Dominant Applications for Rigid-Flex PCBs

Rigid-flex boards are the go-to solution for applications where space, weight, and reliability are non-negotiable. Key markets include:

- Aerospace and Defense: Avionics, missile guidance systems, and satellite electronics where durability and weight reduction are critical.

- Medical Devices: Pacemakers, hearing aids, and endoscopic cameras that require biocompatible, miniaturized, and highly reliable circuits.

- Wearable Technology: Smartwatches, fitness trackers, and AR/VR headsets where the electronics must conform to the human body.

Conclusion: Matching the PCB to Your Project’s DNA

The debate between Multilayer PCB vs. Rigid-Flex PCB is not about which is universally “better,” but which is fundamentally right for your specific application. A multilayer PCB remains the industry standard for a reason: it delivers exceptional performance and density at an unbeatable price point for a vast range of static applications. It is the workhorse of the electronics world.

A rigid-flex PCB, on the other hand, is a specialized solution for conquering mechanical and spatial challenges. It represents a higher investment in fabrication, but pays dividends in reliability, miniaturization, and design innovation. By carefully evaluating your project’s unique demands against the strengths of each technology, you can make an informed decision that ensures your product is not only functional but also competitive, reliable, and cost-effective in the long run.

Frequently Asked Questions (FAQ)

Is rigid-flex always more expensive than a multilayer PCB assembly?

The upfront fabrication cost of a single rigid-flex board is almost always higher. However, when you factor in the total system cost—including multiple rigid boards, connectors, cables, and the labor to assemble them—the rigid-flex solution can sometimes be less expensive overall, especially for complex, low-to-mid volume products.

Can you have a multilayer rigid-flex PCB?

Yes. In fact, most rigid-flex PCBs are inherently multilayer. Both the rigid sections and the flexible sections can contain multiple conductive layers to accommodate complex routing, just like a standard multilayer board.

How does rigid-flex improve reliability?

It improves reliability primarily by eliminating connectors and solder joints between boards. These are the most common points of mechanical and electrical failure in an electronic system. By creating continuous, integrated connections, a rigid-flex board is far less susceptible to problems caused by shock, vibration, and thermal cycling.

Multilayer PCB, Rigid-Flex PCB, Multilayer PCB vs Rigid-Flex PCB, printed circuit board, PCB design, flexible circuits, what is the difference between multilayer and rigid-flex pcb, when to use rigid-flex pcb, cost of rigid-flex pcb, multilayer pcb applications, rigid-flex pcb advantages