For the vast majority of wearable electronics, Flexible PCBs are unequivocally the better choice due to their inherent ability to bend, conform to the human body, and their extremely lightweight and thin profile. These characteristics are essential for user comfort and innovative product design in devices like smartwatches and fitness trackers. However, Aluminum PCBs serve a critical, niche role for specific high-power components within a wearable ecosystem that demand superior heat dissipation, such as high-intensity LED arrays or power management modules.

Table of Contents

- Understanding the Core Contenders: What Are We Comparing?

- Head-to-Head Comparison: Aluminum PCB vs. Flexible PCB at a Glance

- Why is PCB Choice So Critical for Wearable Technology? The Key Decision Factors

- The Verdict: Which PCB Reigns Supreme for Specific Wearable Applications?

- Is There a “Best of Both Worlds”? Introducing the Rigid-Flex PCB

- Final Conclusion: Choosing the Right PCB for Your Wearable Innovation

- Frequently Asked Questions (FAQ)

Understanding the Core Contenders: What Are We Comparing?

Before diving into a direct comparison, it’s crucial to understand the fundamental construction and purpose of each printed circuit board (PCB) type. Their material composition dictates their primary strengths and weaknesses, especially within the demanding context of wearable technology.

What is a Flexible PCB (Flex Circuit)?

A Flexible PCB, often called a flex circuit, is a printed circuit board built on a pliable, thin, and lightweight substrate. Instead of the rigid fiberglass (FR-4) used in traditional boards, flex circuits use a flexible polymer film, most commonly polyimide (PI). This material allows the entire circuit board to bend, twist, and fold without damaging the conductive copper traces laminated onto it. This dynamic capability enables 3D product designs, reduces weight, and eliminates the need for bulky connectors between separate rigid boards, making them a cornerstone of modern compact electronics.

The primary advantage of flexible PCBs in wearables is their ability to conform to non-planar shapes. Imagine the circuitry inside a smartwatch band, a biometric sensor woven into a shirt, or the delicate electronics packed into a pair of smart glasses. These applications are only possible because the electronics can bend with the product’s form and the user’s movement. They are designed for dynamic stress and vibration, offering enhanced durability in devices that are constantly in motion.

What is an Aluminum PCB (Metal Core PCB)?

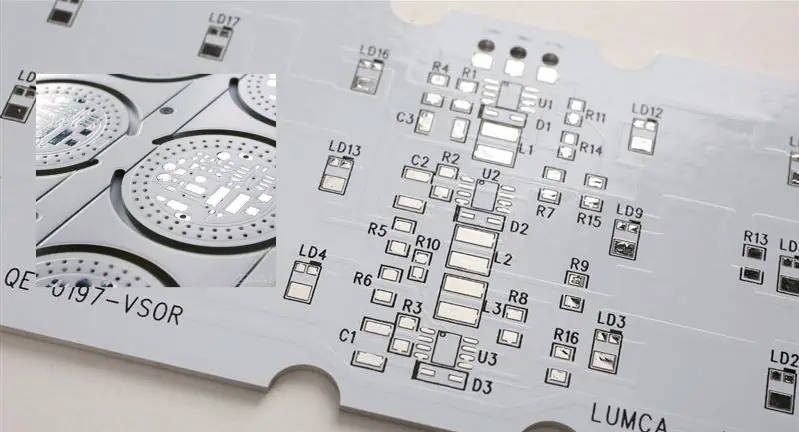

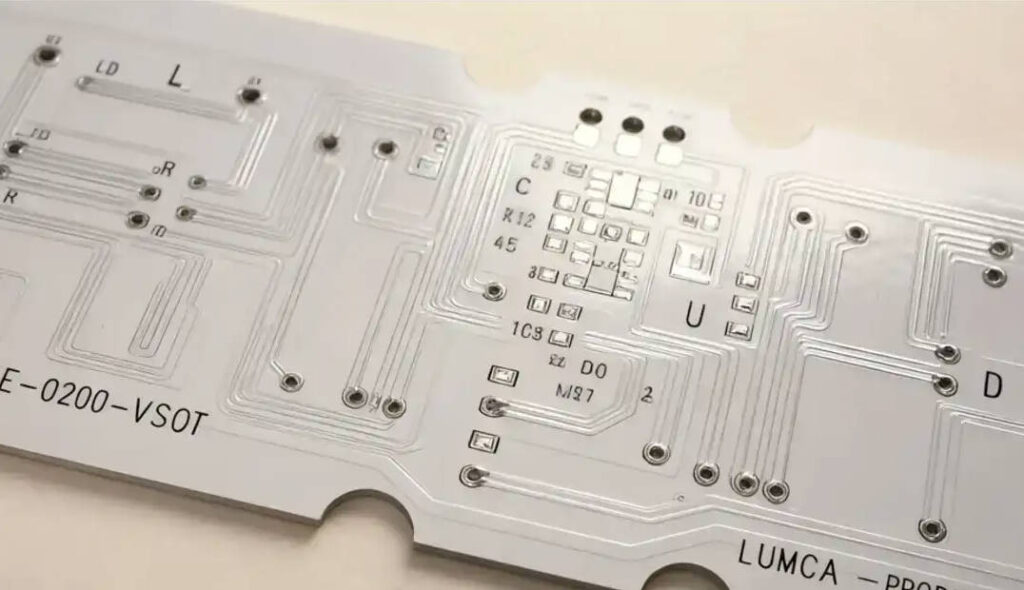

An Aluminum PCB is a type of Metal Core PCB (MCPCB) that uses a metal, typically aluminum, as its base material instead of FR-4. Its structure consists of a copper circuit layer, a thermally conductive but electrically insulating dielectric layer, and a thick aluminum base layer. This construction is designed for one primary purpose: outstanding thermal management. The aluminum base acts as a built-in heat sink, rapidly drawing heat away from critical components and dissipating it into the environment.

This property makes Aluminum PCBs the go-to solution for high-power applications where thermal buildup can lead to component failure or reduced performance, such as high-brightness LED lighting, power converters, and automotive electronics. However, this robust thermal performance comes at the cost of flexibility. Aluminum PCBs are completely rigid, significantly heavier, and bulkier than their flexible counterparts, characteristics that are generally undesirable for a device worn directly on the body.

Head-to-Head Comparison: Aluminum PCB vs. Flexible PCB at a Glance

To clarify the differences, here is a direct comparison of the key attributes of each PCB type relevant to wearable device design.

| Feature | Flexible PCB (Flex Circuit) | Aluminum PCB (MCPCB) |

|---|---|---|

| Substrate Material | Polyimide (PI), Polyester (PET) | Aluminum core with a thermally conductive dielectric layer |

| Flexibility/Rigidity | Highly flexible, can be bent and folded repeatedly | Completely rigid and non-pliable |

| Thermal Conductivity | Low. Polyimide is a thermal insulator. | Extremely high. The aluminum core acts as a heat sink. |

| Weight & Profile | Very lightweight and thin | Heavier and thicker due to the metal base |

| Primary Advantage | Conformability, space-saving, and light weight | Superior heat dissipation and structural rigidity |

| Common Wearable Use Case | Main boards, sensor connections, battery circuits in smartwatches, fitness bands, smart clothing | Niche use in high-power components like biometric sensor LEDs or charging modules |

| Cost | Generally higher per unit area than rigid boards, but can reduce total system cost | Cost-effective for its thermal performance, but more expensive than standard FR-4 |

Why is PCB Choice So Critical for Wearable Technology? The Key Decision Factors

Choosing between a flexible and an aluminum PCB for a wearable device isn’t just a technical decision; it fundamentally impacts user experience, product aesthetics, and device reliability. Several key factors must be weighed.

Factor 1: Flexibility and Conformability – The Ultimate Wearable Trait

The defining characteristic of a wearable is that it is worn. This means it must be comfortable, unobtrusive, and able to move with the human body. Flexible PCBs excel here. Their ability to bend around a wrist, fit within the curve of a headset, or be integrated into fabric is a non-negotiable requirement for most wearable form factors. An Aluminum PCB, being completely rigid, simply cannot meet this demand. For any part of a device that needs to contour to the body, a flexible circuit is the only viable option.

Factor 2: Thermal Management – How Do They Handle the Heat?

Heat is a major challenge in compact electronics. Processors, LEDs, and charging circuits all generate thermal energy that must be managed to ensure component longevity and, critically for wearables, user safety and comfort. Here, the roles are reversed. Aluminum PCBs are masters of thermal dissipation. The metal core can efficiently pull heat away from a high-power LED used for heart rate sensing (photoplethysmography) or a fast-charging IC. A standard flexible PCB, with its polyimide base, is a poor heat conductor and can lead to thermal hotspots if not carefully designed. This is the single most compelling reason to consider an Aluminum PCB for a specific, heat-intensive part of a wearable.

Factor 3: Size, Weight, and Profile – The Battle Against Bulk

Wearables need to be as small and light as possible. Every gram and every millimeter counts. Flexible PCBs contribute significantly to miniaturization. They can be folded into tight spaces, eliminating the volume that would be taken up by multiple rigid boards and their connectors. Their inherent thinness and the lightness of polyimide make them featherweight champions. In contrast, Aluminum PCBs are defined by their metal core, which adds substantial weight and thickness, making them unsuitable for the main body of a wearable device.

Factor 4: Durability and Reliability – Surviving Daily Life

Wearable devices are subjected to constant motion, vibration, and occasional impacts. Flexible circuits offer excellent mechanical durability. Their ability to bend absorbs stresses that would crack the solder joints on a rigid board. This resilience makes them more reliable in dynamic environments. While Aluminum PCBs are structurally very strong and rigid, this same rigidity makes them and their mounted components more vulnerable to failures caused by shock and vibration, as there is no give in the system.

Factor 5: Cost and Manufacturing Complexity

While the per-unit area cost of a flexible PCB can be higher than that of an Aluminum PCB, a total system cost analysis often tells a different story. By eliminating connectors, wires, and other assembly components, a single flex circuit can reduce assembly time and potential points of failure, potentially lowering the overall product cost. Aluminum PCB manufacturing is a well-established process, but its application is specific. Integrating a small, rigid aluminum board into a flexible design adds complexity and connection points, which must be factored into the final cost and reliability assessment.

The Verdict: Which PCB Reigns Supreme for Specific Wearable Applications?

The right choice depends entirely on the specific function and location of the circuit within the wearable device.

For Smartwatches and Fitness Trackers: Flexibility is King

For the main logic board, display connections, and sensor arrays that must fit into a compact, curved chassis, flexible PCBs are the default and superior choice. Their ability to wrap around batteries and other components is essential for achieving the sleek designs consumers expect.

For Smart Clothing and E-Textiles: Only Flex Circuits Apply

In applications where electronics are directly integrated into fabric, there is no contest. The circuit must be able to bend, stretch, and move with the textile. Flexible PCBs, especially those designed with stretchable interconnects, are the only technology that can fulfill this requirement. An aluminum board is a non-starter.

For High-Intensity Medical or Biometric Sensors: A Case for Aluminum?

This is where nuance is key. Consider a wearable device for phototherapy that uses a dense array of high-power LEDs. These LEDs generate significant heat that a polyimide substrate cannot handle. In this scenario, the best design might involve mounting the LEDs on a small Aluminum PCB to act as an efficient heat sink. This small, rigid module would then be connected to the main control unit via a flexible circuit. Here, the Aluminum PCB isn’t the primary board, but a specialized component chosen for its unique thermal properties.

Is There a “Best of Both Worlds”? Introducing the Rigid-Flex PCB

For many advanced wearables, the optimal solution is a hybrid: the Rigid-Flex PCB. This construction combines rigid board sections (typically made of FR-4) with integrated flexible circuit sections. This allows engineers to mount sensitive, high-pin-count components onto stable rigid platforms while using the flexible parts to create dynamic, pre-routed connections that fold into the final product shape. A Rigid-Flex board could even incorporate a rigid section made with a metal core for thermal management, truly merging the benefits of both technologies into a single, highly integrated package. This approach offers the highest level of design sophistication, eliminating connectors entirely and maximizing space utilization, though it often comes at a higher initial cost.

Final Conclusion: Choosing the Right PCB for Your Wearable Innovation

The debate between Aluminum and Flexible PCBs for wearables has a clear winner for general-purpose applications. Flexible PCBs are the dominant and most suitable technology for the core circuitry of wearable devices, thanks to their unmatched flexibility, light weight, and space-saving advantages.

However, to dismiss Aluminum PCBs entirely would be a mistake. Their role is not as a primary board but as a specialized problem-solver for thermal management. The future of advanced wearable design lies in a hybrid approach: using flexible and rigid-flex circuits for the overall structure and strategically placing small Aluminum PCBs only where extreme heat dissipation is a critical design requirement. The ultimate decision rests on a careful analysis of your device’s form factor, thermal output, and overall system architecture.

Frequently Asked Questions (FAQ)

Can you use an Aluminum PCB in a smartwatch?

You would not use an Aluminum PCB for the main board of a smartwatch due to its rigidity and weight. However, a tiny Aluminum PCB might be used internally for a specific component that generates a lot of heat, such as the module for high-power LEDs used for advanced blood oxygen or heart rate monitoring, and then be connected to the main flexible board.

Are flexible PCBs more expensive than aluminum PCBs?

On a simple square-inch to square-inch comparison, flexible PCB material and processing can be more expensive. However, when considering the total cost of the product, flexible PCBs can be more economical by eliminating the need for connectors, wiring harnesses, and reducing assembly labor, which simplifies the design and improves reliability.

What is the main advantage of an aluminum PCB?

The single greatest advantage of an Aluminum PCB is its excellent thermal conductivity. The metal core acts as an integrated heat sink, efficiently transferring heat away from electronic components. This makes it ideal for high-power applications where managing heat is the primary design challenge.

Aluminum PCB, Flexible PCB, Wearable Electronics, Rigid-Flex PCB, aluminum pcb vs flexible pcb, best pcb for smartwatches, flexible pcb for medical wearables, thermal management in wearable tech, pcb for compact electronic devices, aluminum pcb heat dissipation, what is a flexible pcb, benefits of rigid-flex pcb, Flex Circuits, Metal Core PCB, MCPCB, Wearable Technology