Use an Aluminum PCB over a standard FR4 PCB in industrial electronics primarily when superior thermal management is critical to the application’s performance, reliability, and longevity. While FR4 is the cost-effective industry standard for general-purpose electronics, aluminum PCBs are the definitive choice for high-power applications where heat dissipation is the primary engineering challenge. These applications include high-power LED lighting, power conversion systems, motor controllers, and automotive electronics, where excess heat can lead to component failure and reduced operational life. The aluminum base acts as an integrated heat sink, efficiently drawing thermal energy away from sensitive components, a task for which FR4 is fundamentally ill-equipped.

Table of Contents

- What Are the Fundamental Differences? A Head-to-Head Comparison

- Why Choose an Aluminum PCB? The Core Advantages in an Industrial Context

- When Does the Traditional FR4 PCB Still Reign Supreme?

- Critical Decision Factors: How to Choose the Right PCB for Your Industrial Application

- Real-World Industrial Applications: Where Aluminum and FR4 Shine

- Conclusion: Making the Strategic Choice for Industrial Excellence

What Are the Fundamental Differences? A Head-to-Head Comparison

Before diving into specific use cases, it’s essential to understand the core structural and material differences between Aluminum and FR4 PCBs. FR4 is a composite material made of woven fiberglass cloth with an epoxy resin binder, making it an excellent electrical insulator but a poor thermal conductor. An Aluminum PCB, often called a Metal Core PCB (MCPCB) or Insulated Metal Substrate (IMS), is a layered board with a metal base. This fundamental difference in construction dictates jejich respective strengths and weaknesses.

symptômes of efficient heat dissipationLow cost and electrical insulation

| Parameter | Aluminum PCB | FR4 PCB |

|---|---|---|

| Core Material | Aluminum alloy (e.g., 5052, 6061) | Woven fiberglass cloth with epoxy resin |

| Thermal Conductivity | High (typically 1.0 – 9.0 W/mK for the board) | Very Low (typically 0.3 – 0.5 W/mK) |

| Primary Advantage | ||

| Mechanical Strength | High; resistant to breakage and flex | Moderate; can break or crack under stress |

| Cost | Higher | Lower |

| Layer Complexity | Primarily single or double-sided | Can support complex multi-layer (30+) designs |

| Weight | Heavier for the same dimensions | Lighter |

| Coefficient of Thermal Expansion (CTE) | Lower; more stable with temperature changes | Higher; more prone to warping |

Deconstructing the Aluminum PCB (MCPCB)

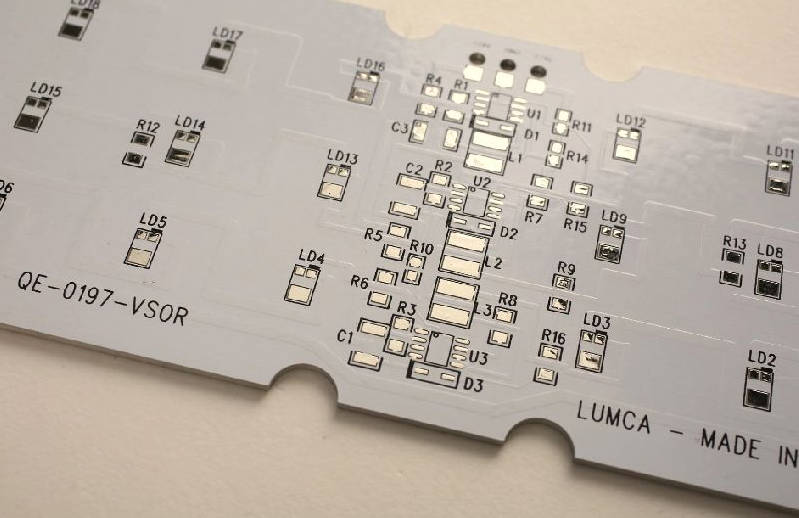

An Aluminum PCB is not simply a circuit etched onto a sheet of aluminum. It’s a sophisticated laminate designed for thermal transfer. Its structure typically consists of three critical layers:

- The Aluminum Base: This is the thickest layer and provides the mechanical structure and primary path for heat dissipation.

- The Dielectric Layer: A very thin, thermally conductive but electrically insulating layer. This is the most crucial and technologically advanced part of an MCPCB, as it must allow heat to pass through easily while preventing any short circuits to the aluminum base.

- The Copper Circuit Layer: This is the standard copper foil (typically 1-4 oz) where the electronic circuit is etched, identical to a conventional PCB.

The effectiveness of an Aluminum PCB is directly tied to the quality and thermal impedance of this dielectric layer. A lower thermal impedance means faster heat transfer from the copper to the aluminum base.

Why Choose an Aluminum PCB? The Core Advantages in an Industrial Context

The decision to invest in an Aluminum PCB is driven by a need for performance and reliability that FR4 simply cannot provide. In harsh industrial settings, these advantages often justify the higher initial cost.

Unmatched Thermal Dissipation: The Primary Driver

This is the single most important reason to choose an Aluminum PCB. Industrial electronics, especially in power applications, generate substantial heat. Components like power MOSFETs, voltage regulators, and high-brightness LEDs operate most efficiently and have the longest lifespan within a specific temperature range. Exceeding this range leads to degraded performance, color shifts (in LEDs), and eventual catastrophic failure. An FR4 board, with its thermal conductivity of around 0.3 W/mK, traps heat around the component, creating localized “hot spots.”

In stark contrast, an Aluminum PCB’s structure is designed to combat this. The aluminum base, with a material conductivity often exceeding 200 W/mK, acts as a built-in heat sink. The thermally conductive dielectric layer efficiently funnels heat from the copper trace directly into the aluminum base, which then dissipates it into the ambient environment or to a larger attached heatsink. This active cooling mechanism keeps component junction temperatures low, ensuring stable operation and dramatically extending the product’s service life. It often eliminates the need for bulky, separate heat sinks, fans, and other cooling hardware, simplifying the overall mechanical design.

Superior Mechanical Strength and Durability

Industrial environments are unforgiving. Equipment is often subjected to mechanical shock, vibration, and accidental impacts. FR4, being a glass-reinforced epoxy, is relatively brittle. It can crack or fracture, especially at mounting points or around large, heavy components, leading to broken traces and complete circuit failure. Aluminum PCBs, on the other hand, are inherently far more robust.

The aluminum substrate provides exceptional rigidity and strength, preventing the board from flexing, warping, or breaking during assembly or in the field. This makes them ideal for applications with significant vibration, such as in motor drives, automotive systems, or heavy machinery control units. The added durability reduces the risk of field failures, which is a critical consideration for industrial equipment where downtime is extremely costly.

Enhanced Dimensional Stability

All materials expand and contract with changes in temperature, a property measured by the Coefficient of Thermal Expansion (CTE). FR4 has a significantly higher CTE than the ceramic and metal components mounted on it. This mismatch can induce mechanical stress on solder joints during thermal cycling (powering on and off), potentially leading to joint fatigue and failure over time.

Aluminum has a CTE that is much closer to that of the components mounted on the board. This results in superior dimensional stability across a wide range of operating temperatures. The board expands and contracts more uniformly with the components, reducing stress on solder joints and improving the long-term reliability of the entire assembly, a crucial factor in products designed for a service life of a decade or more.

When Does the Traditional FR4 PCB Still Reign Supreme?

Despite the clear advantages of aluminum in certain scenarios, FR4 remains the most widely used PCB material for good reason. For a vast majority of electronic applications, it provides the perfect balance of performance, cost, and design freedom.

The Undeniable Cost-Effectiveness for Mass Production

The primary advantage of FR4 is its low cost. The raw materials are inexpensive, and the manufacturing process is mature, highly optimized, and scaled for massive volumes globally. For any low-power or general-purpose industrial application where thermal load is not a concern—such as in control panels, sensor interfaces, or data acquisition modules—using an Aluminum PCB would be an unnecessary and prohibitive expense. The cost-performance ratio of FR4 is simply unbeatable for these applications.

Versatility and Multi-Layer Design Flexibility

Modern electronics demand complexity. FR4 is the master of complex, high-density designs. It can be easily manufactured in multi-layer configurations, with some designs exceeding 30 layers. This allows engineers to route complex high-speed signals, create dense component layouts, and manage signal integrity with dedicated ground and power planes. Aluminum PCBs, by their nature, are much more difficult and expensive to produce in multi-layer versions. They are typically limited to single or double-sided designs, which severely restricts routing options for complex digital or mixed-signal circuits.

Excellent Electrical Insulation Properties

FR4 is, by its very nature, an outstanding electrical insulator. This is its primary function. There is no risk of the substrate causing a short circuit. While Aluminum PCBs have a dielectric layer, it is extremely thin and can be susceptible to failure under high voltage stress or due to manufacturing defects. For very high-voltage applications, the robust and predictable insulating properties of a thick FR4 board are often preferred for safety and certification purposes.

Critical Decision Factors: How to Choose the Right PCB for Your Industrial Application

How do you make the final call? The choice between aluminum and FR4 is not just a technical one; it’s a strategic decision that impacts cost, reliability, and time-to-market. Ask yourself these key questions.

Analyzing Your Thermal Load: Is Heat the Enemy?

This is the first and most important question. Perform a thermal analysis of your circuit. Identify the heat-generating components (e.g., MOSFETs, IGBTs, LEDs, power resistors). Calculate the total power dissipation. If the components will operate near or above their maximum rated temperature with a standard FR4 board (even with a small heat sink), you have a strong case for an Aluminum PCB. If the total power dissipation is low and components remain cool, FR4 is the logical choice.

Evaluating the Operating Environment: Shock, Vibration, and Stress

Where will this product live? If it’s destined for a stationary, climate-controlled server room, FR4’s mechanical properties are likely sufficient. If it will be mounted on a vibrating motor, inside a vehicle, or in heavy machinery subject to physical stress, the superior durability and rigidity of an Aluminum PCB can be a crucial factor in preventing field failures and ensuring long-term reliability.

Balancing Budget vs. Long-Term Reliability (TCO)

Consider the Total Cost of Ownership (TCO), not just the initial board cost. An Aluminum PCB might cost 2-5x more than an equivalent FR4 board. However, if it prevents field failures, service calls, and warranty claims, its TCO can be significantly lower. If a failure in the field could lead to costly downtime for your customer or a safety hazard, the added upfront cost of an Aluminum PCB is a wise investment in risk mitigation.

Considering Circuit Complexity and Layer Count

How complex is your circuit? If you need a high-density, 8-layer board with controlled impedance for high-speed digital signals, FR4 is your only practical option. The design constraints of Aluminum PCBs (mostly single-sided) make them unsuitable for this level of complexity. If your circuit is a relatively simple power or driver circuit that can be laid out on a single layer, then aluminum remains a viable option.

Real-World Industrial Applications: Where Aluminum and FR4 Shine

Case Studies for Aluminum PCBs

- High-Power LED Lighting: This is the quintessential application. Industrial high-bay lights, streetlights, and automotive headlights generate immense heat. Aluminum PCBs are essential to draw heat away from the LED chips, preventing color shift and ensuring a 50,000+ hour lifespan.

- Power Supplies and Converters: Switching power supplies, AC/DC converters, and inverters use power transistors that dissipate significant heat. Mounting them on an Aluminum PCB provides direct, efficient cooling, allowing for a more compact and reliable power unit.

- Motor Controllers: Variable Frequency Drives (VFDs) and brushless DC motor controllers use powerful IGBTs or MOSFETs to drive motors. These components are prime candidates for mounting on an Aluminum PCB to manage the intense thermal load during operation.

Case Studies for FR4 PCBs

- PLC and Automation Controllers: The main CPU, memory, and I/O logic in a Programmable Logic Controller (PLC) are complex, multi-layer digital circuits with low power dissipation. FR4 is the perfect, cost-effective choice.

- Sensor and Instrumentation: A board for a temperature or pressure sensor interface involves low-power analog and digital circuitry. Heat is not a concern, but cost and small form factor are. FR4 is ideal.

- Prototyping and General Electronics: For any new design, development board, or low-volume general-purpose circuit, FR4’s low cost, versatility, and fast turnaround time make it the default standard.

Conclusion: Making the Strategic Choice for Industrial Excellence

The choice between an Aluminum PCB and an FR4 PCB is a classic engineering trade-off. It is not about which material is “better” overall, but which is unambiguously right for a specific industrial application.

FR4 remains the undisputed king solution of cost-effectiveness and design complexity, making it the default choice for the vast majority of low-power digital and analog circuits. However, when your industrial design’s primary challenge is managing heat, and its success hinges on long-term reliability in a demanding environment, the Aluminum PCB is not a luxury—it’s an essential engineering tool. By prioritizing thermal performance, mechanical durability, and long-term reliability, the higher initial investment in an Aluminum PCB pays dividends, ensuring your product stands up to the rigors of the industrial world.