When selecting a printed circuit board (PCB) for applications in harsh environments, aluminum PCBs consistently outperform their plastic (FR-4) counterparts due to superior thermal conductivity and mechanical strength. While standard plastic PCBs are the cost-effective workhorse for most consumer electronics, they falter under the extreme stress of high temperatures, physical shock, and vibration, making aluminum-backed boards the essential choice for reliability and longevity in demanding sectors like automotive, industrial, and high-power LED lighting. This decision is not merely about material preference; it’s a critical engineering choice that directly impacts product performance, safety, and lifespan.

Table of Contents

- What Exactly Makes an Environment ‘Harsh’ for a PCB?

- The Contenders: Aluminum PCB vs. Plastic (FR-4) PCB at a Glance

- Deep Dive: The Unmatched Durability of Aluminum PCBs

- The Case for Plastic (FR-4) PCBs: When Are They Sufficient?

- Application Spotlight: Where Each PCB Type Shines

- How to Choose? Key Questions for Your Project

- Conclusion: Prioritizing Durability for Mission-Critical Applications

What Exactly Makes an Environment ‘Harsh’ for a PCB?

Before comparing the materials, it’s crucial to understand what “harsh” truly means in the context of electronics. A harsh environment introduces stressors that can degrade a PCB’s materials, compromise its electrical integrity, and ultimately lead to catastrophic failure. Understanding these factors is the first step in selecting the appropriate substrate.

Thermal Stress and High Temperatures

This is arguably the most common and damaging environmental factor. Heat is generated not only by the external environment (e.g., under the hood of a car) but also by the high-power components mounted on the PCB itself. Excessive heat can cause the board to expand at different rates (known as a high Coefficient of Thermal Expansion or CTE), leading to delamination (layers separating), solder joint fatigue, and a drastic reduction in the lifespan and performance of electronic components.

Mechanical Shock and Vibration

In applications like automotive, aerospace, and heavy industrial machinery, PCBs are subjected to constant vibration and occasional physical shocks. A brittle or flexible PCB can easily crack under this stress. Solder joints can fracture, and components can be shaken loose from the board, resulting in intermittent or total system failure. The board’s structural rigidity is paramount in these scenarios.

Chemical and Moisture Exposure

Industrial settings often involve exposure to corrosive chemicals, oils, and cleaning agents. Similarly, outdoor or marine applications introduce high levels of humidity and salt spray. These elements can corrode copper traces, degrade the substrate material, and create short circuits, rendering the entire electronic assembly useless.

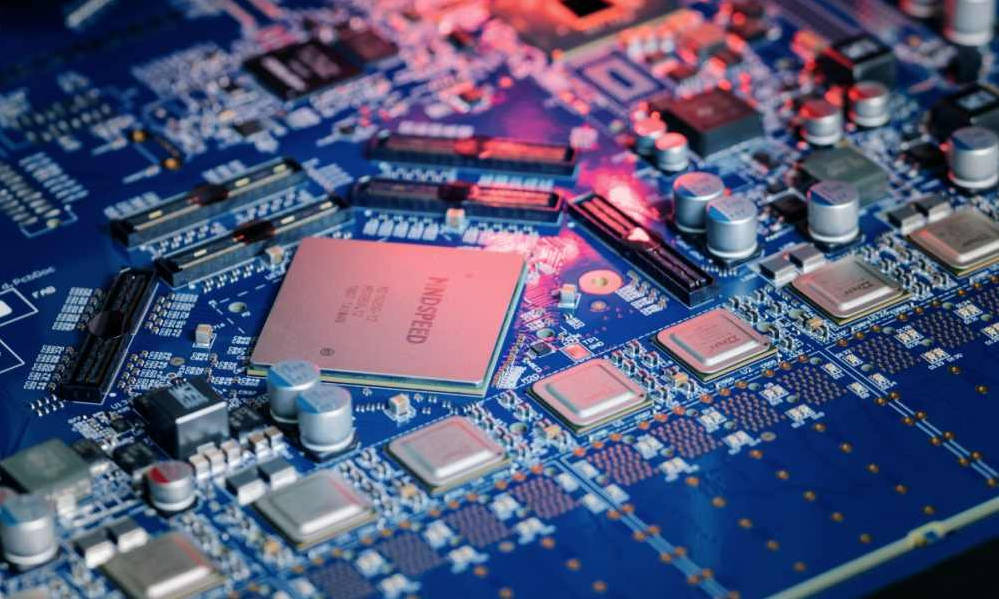

The Contenders: Aluminum PCB vs. Plastic (FR-4) PCB at a Glance

To simplify the choice, a direct comparison reveals the stark differences in material properties. The most common “plastic” PCB is FR-4, a glass-reinforced epoxy laminate. We will use it as the benchmark for comparison against a typical aluminum-clad PCB.

| Feature | Aluminum PCB | Plastic PCB (FR-4) |

|---|---|---|

| Thermal Conductivity | Excellent (~138-200 W/mK for the base) | Very Poor (~0.25 W/mK) |

| Mechanical Strength | High (Resists bending, warping, and impact) | Moderate (Can be brittle and prone to fracture) |

| Heat Dissipation | Acts as a built-in heat sink, transferring heat away | Traps heat, requiring external heat sinks |

| Durability & Lifespan | Significantly longer in high-stress environments | Reduced lifespan under thermal and mechanical stress |

| Cost | Higher initial cost | Low cost, industry standard |

| Weight | Heavier | Lighter |

| Manufacturing Complexity | More complex due to the dielectric layer | Simple, well-established process |

Deep Dive: The Unmatched Durability of Aluminum PCBs

An aluminum PCB, also known as a Metal Core PCB (MCPCB), is not simply a piece of aluminum with circuits on it. It’s a sophisticated laminate structure typically composed of a copper circuit layer, a thermally conductive but electrically insulating dielectric layer, and a thick aluminum base layer. This construction is the source of its incredible durability.

Superior Thermal Management: The Core Advantage

The primary reason engineers choose aluminum PCBs is for unparalleled thermal management. Heat generated by components like high-power LEDs or voltage regulators passes through the thin dielectric layer and is rapidly spread across the entire aluminum base. The aluminum base acts as a highly effective heat sink, dissipating the thermal energy into the surrounding environment. This efficiency prevents the formation of “hot spots” on the board, which are a primary cause of component failure in FR-4 designs. By keeping components running cooler, their operational lifespan and stability are dramatically increased.

Incredible Mechanical Strength and Rigidity

Unlike FR-4, which can be brittle and prone to flexing, aluminum provides a robust and rigid foundation for the circuitry. This structural integrity is vital in environments with high vibration or the risk of physical impact. The material’s rigidity prevents the board from warping during thermal cycling or breaking when dropped or struck. This means solder joints and delicate component leads are protected from the mechanical stresses that would quickly cause failure on a less durable plastic substrate. Furthermore, the dimensional stability of aluminum ensures that the board maintains its shape and form over time, even in fluctuating temperatures.

Enhanced Lifespan and Long-Term Reliability

The combination of superior thermal dissipation and mechanical strength directly translates to a longer, more reliable product life. By mitigating the two biggest threats to a PCB—heat and physical stress—aluminum PCBs ensure that the electronic assembly operates within its safe temperature limits and remains physically intact. For mission-critical systems in automotive safety, medical devices, or industrial automation, this enhanced reliability is not just a benefit; it’s a requirement. The higher initial cost of an aluminum PCB is often offset by lower failure rates, reduced warranty claims, and a more trustworthy end product.

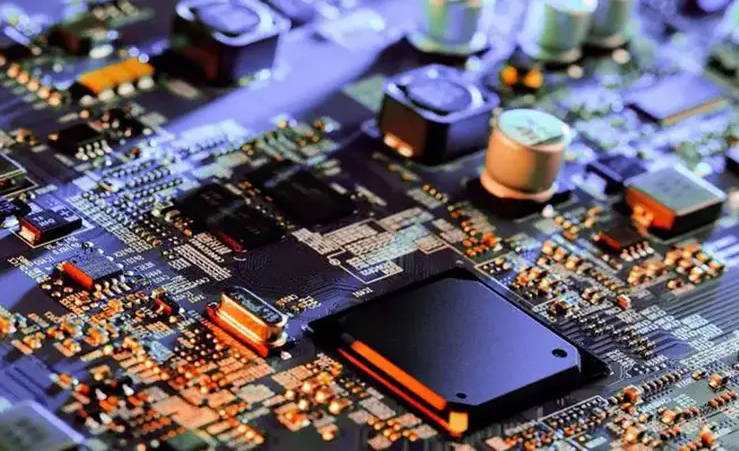

The Case for Plastic (FR-4) PCBs: When Are They Sufficient?

Despite the clear advantages of aluminum in harsh conditions, the vast majority of PCBs in the world are made from FR-4. There are excellent reasons for this, and understanding its strengths helps define its proper use cases.

Cost-Effectiveness and Manufacturing Simplicity

FR-4 is the undisputed champion of cost. The raw materials—woven fiberglass cloth impregnated with an epoxy resin—are inexpensive and readily available. The manufacturing processes for FR-4 are mature, standardized, and highly optimized for mass production, including complex multi-layer designs. For a massive range of consumer electronics where environmental stresses are minimal and cost is a primary driver, FR-4 is the logical and most economical choice.

Natural Electrical Insulation Properties

FR-4 is an excellent electrical insulator by its very nature. This simplifies board design, as there’s no inherent risk of the substrate shorting out the circuit. In contrast, aluminum PCBs require a specialized dielectric layer to isolate the copper circuitry from the conductive aluminum base. While highly effective, this dielectric layer adds a step to manufacturing and represents a potential, albeit rare, point of failure if its integrity is compromised.

Understanding the Limitations in Demanding Scenarios

The very properties that make FR-4 a good insulator also make it a terrible thermal conductor. It traps heat around components, effectively “baking” them over time. In a high-power or high-temperature environment, this thermal buildup is its Achilles’ heel. While designers can add external heat sinks, fans, and other thermal management solutions, this adds cost, complexity, and bulk. At a certain point, it becomes more efficient and reliable to use a substrate that has thermal management built into its core, which is precisely where aluminum PCBs take over.

Application Spotlight: Where Each PCB Type Shines

The theoretical differences are best understood through real-world applications. The choice of PCB substrate is dictated entirely by the demands of the final product’s operating environment.

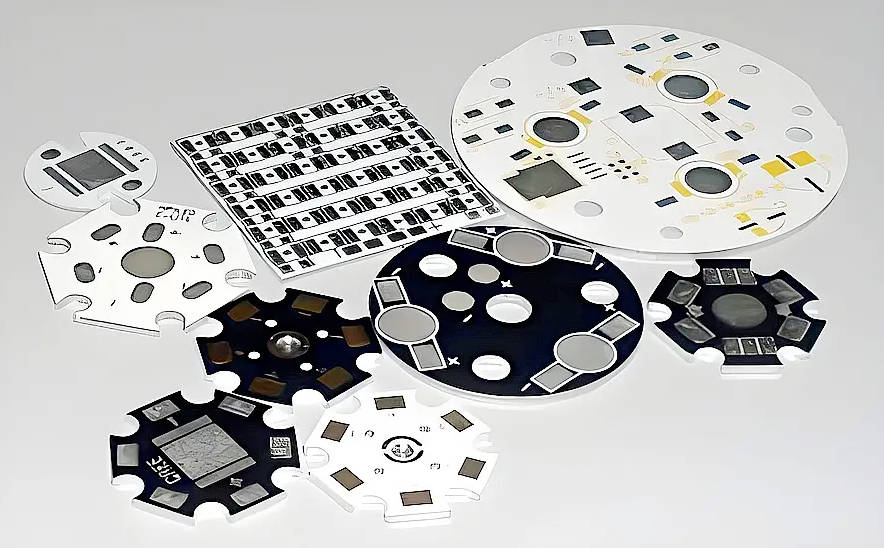

Aluminum PCBs in Action: Power and Resilience

- High-Power LED Lighting: Streetlights, stadium lights, and automotive headlights generate immense heat. Aluminum PCBs are essential for drawing this heat away from the LED chips, preventing color shifts and premature failure.

- Power Supplies & Converters: Components like MOSFETs and regulators in power electronics dissipate significant heat. Aluminum PCBs provide the necessary cooling to ensure stable and reliable power delivery.

- Automotive Electronics: From engine control units (ECUs) to ABS systems, PCBs in vehicles must withstand extreme temperatures and constant vibration. Aluminum’s durability is critical for safety and performance.

- Industrial Controls: Factory equipment and motor drivers operate in demanding environments. Aluminum PCBs ensure these systems remain reliable under heavy load and physical stress.

Plastic PCBs’ Domain: The Everyday Standard

- Consumer Electronics: Televisions, smartphones, toys, and home appliances operate in stable, climate-controlled environments where cost is paramount and thermal loads are low. FR-4 is the perfect fit.

- Prototyping and Hobbyist Projects: FR-4’s low cost and ease of manufacturing make it the go-to for developing and testing new circuit designs.

- Low-Power Devices: IoT sensors, remote controls, and other battery-powered devices generate negligible heat, making the thermal benefits of aluminum unnecessary.

How to Choose? Key Questions for Your Project

When you’re at the design stage, making the right decision comes down to answering a few critical questions about your application’s requirements. Your answers will clearly point toward either an aluminum or plastic solution.

- What is the maximum continuous operating temperature of the key components? If you are dealing with high-power LEDs, power transistors, or processors that run hot, thermal management is your primary concern. This strongly favors aluminum.

- Will the product be exposed to significant vibration, shock, or risk of impact? For any application that isn’t stationary and protected, from automotive to portable industrial equipment, mechanical robustness is key. This points directly to aluminum.

- What are the consequences of a field failure? If a failure could lead to a safety risk (e.g., automotive braking), significant financial loss (e.g., factory downtime), or is in a location that is difficult to service, the enhanced reliability of aluminum justifies the cost.

- Is cost the single most important design constraint? For high-volume consumer goods in stable environments, the cost savings of FR-4 are undeniable and make it the correct choice.

Conclusion: Prioritizing Durability for Mission-Critical Applications

The debate between aluminum and plastic PCBs is not about which material is “better” overall, but which is right for the job. For the vast world of standard electronics, plastic FR-4 PCBs offer an unbeatable combination of low cost and sufficient performance. However, when the environment turns harsh—with high temperatures, punishing vibrations, and a demand for unwavering reliability—the choice is clear. The superior thermal conductivity and mechanical strength of aluminum PCBs make them the definitive solution for ensuring durability and longevity. Investing in an aluminum substrate is an investment in the resilience and long-term performance of your entire electronic system.