1. Introduction to Ceramic Multilayer PCBs

In the rapidly evolving landscape of electronics, the demand for more robust, compact, and high-performing components is ceaseless. While traditional organic Printed Circuit Boards (PCBs) made from materials like FR-4 have served as the backbone for countless electronic devices, they often hit their limits when faced with extreme conditions such as high temperatures, high frequencies, or demanding power requirements. This is where ceramic PCB technology steps in, offering a superior alternative for critical applications.

A ceramic PCB is a type of circuit board manufactured using ceramic materials, primarily alumina (Al2O3) or aluminum nitride (AlN), as the substrate. Unlike organic PCBs that rely on fiberglass and epoxy resins, ceramic PCBs leverage the inherent thermal, electrical, and mechanical advantages of ceramic, making them indispensable in environments where conventional PCBs would simply fail. For engineers and product developers pushing the boundaries of performance, understanding the nuances of ceramic PCBs is not just an advantage—it’s a necessity. This guide will delve deep into the world of ceramic multilayer PCBs, addressing common questions and providing insights for those considering this advanced technology.

2. Key Advantages and Characteristics

The decision to opt for a ceramic PCB often stems from its distinct advantages, which significantly outperform organic counterparts in specific critical areas.

Superior Thermal Management

One of the most compelling reasons to choose ceramic is its exceptional thermal conductivity. Alumina, a common ceramic substrate, boasts a thermal conductivity of 20-30 W/mK, while aluminum nitride can reach 170-220 W/mK. Compare this to FR-4, which typically ranges from 0.3-0.6 W/mK, and the difference is stark. This high thermal conductivity enables rapid and efficient heat dissipation from active components, preventing overheating and significantly enhancing the lifespan and reliability of electronic devices, particularly in high-power applications. Furthermore, the Coefficient of Thermal Expansion (CTE) of ceramic materials closely matches that of semiconductor silicon chips (around 3-7 ppm/∘C). This CTE matching minimizes thermal stress and strain on soldered joints and chip interconnections during temperature fluctuations, dramatically reducing the risk of fatigue failures and improving long-term device stability.

Excellent Electrical Performance

For high-frequency and high-speed applications, the electrical properties of the PCB substrate are paramount. Ceramic materials offer:

- Low Dielectric Constant (K): Typically ranging from 6 to 10 for alumina and 8 to 9 for aluminum nitride, ceramic provides stable impedance control and minimizes signal delay, crucial for high-frequency signal integrity.

- Low Loss Tangent (tanδ): At high frequencies, energy loss within the dielectric material becomes a significant concern. Ceramic materials exhibit very low loss tangents (e.g., <0.001 at 10 GHz for LTCC), ensuring minimal signal attenuation and efficient power transmission, making them ideal for RF, microwave, and millimeter-wave circuits.

- High Breakdown Voltage and Insulation Resistance: Ceramic substrates provide excellent electrical isolation, preventing crosstalk and short circuits, which is vital for high-voltage applications.

Exceptional Mechanical Properties

Ceramic PCBs are renowned for their robustness and durability:

- High Rigidity and Dimensional Stability: Ceramic substrates maintain their shape and size even under extreme thermal cycling or mechanical stress, ensuring consistent performance.

- Resistance to Harsh Environments: They are inherently resistant to a wide range of chemicals, moisture, and radiation, making them suitable for aerospace, medical, and industrial applications where exposure to harsh conditions is common.

- High Flexural Strength: While brittle, certain ceramic formulations offer significant mechanical strength to withstand operational stresses.

Miniaturization and Integration Capabilities

The precise manufacturing techniques for ceramic PCBs allow for very fine line and spacing capabilities, enabling higher circuit density. This, coupled with the ability to embed passive components (resistors, capacitors, inductors) within the ceramic layers, facilitates significant miniaturization and increased functionality in a smaller footprint.

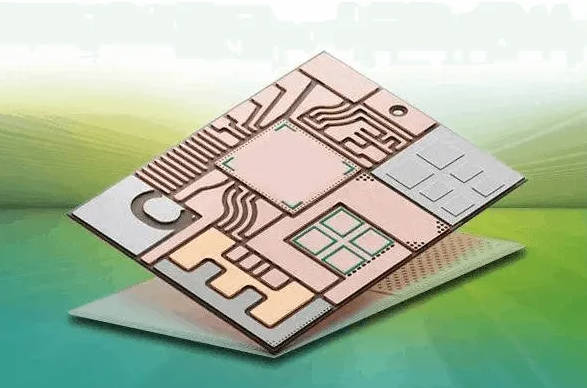

3. Types of Ceramic Multilayer PCBs

The world of ceramic PCBs is primarily categorized by their firing temperatures, leading to distinct manufacturing processes and material properties.

High-Temperature Co-fired Ceramic (HTCC)

HTCC technology involves firing ceramic layers at very high temperatures, typically above 1600$^\circ$C. The ceramic material, usually alumina, is co-fired with refractory metals like tungsten (W) or molybdenum (Mo) which have high melting points.

- Manufacturing Process: Ceramic “green tapes” are prepared, vias are punched, and circuits are screen-printed using refractory metal pastes. These layers are then stacked, laminated under pressure, and co-fired in a hydrogen or inert gas atmosphere.

- Pros: Excellent mechanical strength, high thermal conductivity (especially with AlN HTCC), high hermeticity, and suitability for high-power applications.

- Cons: High processing temperatures limit compatible metallization options (only high-melting-point metals), which can lead to higher resistivity and limits the ability to integrate advanced passive components easily.

- Typical Applications: High-power modules, LED packages, power semiconductors, sensors for harsh environments.

Low-Temperature Co-fired Ceramic (LTCC)

LTCC technology uses glass-ceramic materials that can be co-fired at much lower temperatures, typically between 850$^\circCand900^\circ$C. This lower firing temperature allows for the use of high-conductivity metals like silver (Ag), gold (Au), and copper (Cu) for circuit metallization.

- Manufacturing Process: Similar to HTCC, LTCC involves preparing glass-ceramic green tapes, punching vias, and screen-printing conductive traces and passive components. The layers are then stacked, laminated, and co-fired in a conventional furnace.

- Pros: Enables the integration of high-conductivity metals (Ag, Au), leading to excellent electrical performance at high frequencies. It allows for embedding passive components within layers, offering higher integration and miniaturization. It also boasts good thermal stability and hermeticity.

- Cons: Generally lower thermal conductivity compared to AlN HTCC, and sometimes lower mechanical strength than HTCC.

- Typical Applications: RF and microwave modules, wireless communication devices, automotive sensors, medical implants, high-density packaging.

Comparison of HTCC and LTCC

| Feature | HTCC | LTCC |

| Firing Temperature | >1600∘C | 850∘C – 900∘C |

| Ceramic Material | Alumina (Al2O3), Aluminum Nitride (AlN) | Glass-ceramic compounds |

| Metallization | Tungsten (W), Molybdenum (Mo) | Silver (Ag), Gold (Au), Copper (Cu) |

| Electrical Conductivity | Lower (due to refractory metals) | Higher (due to noble metals) |

| Thermal Conductivity | Very High (especially AlN) | Good (but generally lower than AlN HTCC) |

| Integration | Limited embedded components | High (passive components, cavities) |

| Cost of Metallization | Higher (specialized processes) | Lower (common noble metals) |

| Applications | High power, harsh environments | RF/Microwave, high-density packaging |

Thick Film Ceramic (TFC) and Thin Film Ceramic (TFC)

These are surface deposition technologies often used for specific features or in conjunction with co-fired ceramics.

- Thick Film Ceramic: Involves screen printing conductive, resistive, or dielectric pastes onto a pre-fired ceramic substrate, followed by firing at temperatures typically between 850$^\circCand950^\circ$C. It’s cost-effective for medium-density circuits and discrete components.

- Thin Film Ceramic: Involves highly precise deposition techniques like sputtering or evaporation to create very fine, thin layers of conductors and resistors on a polished ceramic substrate. It offers the highest precision and density, making it suitable for high-frequency ICs and highly sensitive sensors.

4. Design Considerations for Ceramic Multilayer PCBs

Effective ceramic PCB design is a specialized discipline that requires careful attention to material properties, thermal management, and electrical performance.

Material Selection

The choice between alumina, aluminum nitride, or glass-ceramic is fundamental.

- Alumina (Al2O3): A cost-effective and widely used ceramic, offering a good balance of electrical and mechanical properties, and decent thermal conductivity.

- Aluminum Nitride (AlN): The preferred choice for applications demanding extremely high thermal conductivity and excellent CTE matching with silicon. While more expensive, its thermal performance can be critical for high-power devices.

- Glass-Ceramic (for LTCC): Chosen for its lower processing temperature, allowing for noble metal conductors and embedded component integration, crucial for high-frequency modules.

Layer Stack-up and Via Design

Multi-layer ceramic PCBs allow for complex circuit routing and component integration.

- Stack-up Optimization: Careful planning of ground planes, power planes, and signal layers is essential to minimize impedance discontinuities and crosstalk, especially at high frequencies.

- Via Design: Unlike drilling in organic PCBs, vias in ceramic are typically punched during the green tape stage for HTCC/LTCC. Blind and buried vias are commonly used to maximize routing density and improve electrical performance by shortening signal paths. Through vias connect all layers. Thermal vias are strategically placed and filled with conductive materials to efficiently channel heat away from hot spots to heat sinks or radiating surfaces.

Trace Width and Spacing

Ceramic manufacturing allows for significantly finer trace widths and spaces compared to traditional FR-4, often down to 50-100 micrometers for HTCC/LTCC and even finer for thin-film. This enables higher component density and miniaturization. However, designers must adhere to manufacturer-specific design rules, as these limits can vary based on the specific process and material.

Thermal Management Strategies

Given the excellent thermal properties of ceramic, maximizing heat dissipation is a key design goal.

- Integrated Heat Spreaders: Utilizing the ceramic substrate itself as a heat spreader.

- Thermal Vias: A common technique, where an array of vias beneath a heat-generating component is filled with conductive material to create a low thermal resistance path.

- Heat Sinks: Direct attachment of external heat sinks to the ceramic package can further enhance cooling.

- Thermal Simulation: Advanced thermal simulation software is crucial during the ceramic PCB design phase to predict temperature profiles and optimize the layout for efficient heat removal.

Component Mounting and Interconnection

- Die Attach: For bare die attachment, techniques like eutectic bonding (e.g., gold-tin) or conductive epoxies are used to ensure robust electrical and thermal connection to the ceramic substrate.

- Wire Bonding: Gold or aluminum wire bonding is a common method for connecting bare dies to the ceramic circuit.

- Hermetic Sealing: Many ceramic packages are designed for hermetic sealing to protect sensitive components from moisture and environmental contaminants, which is critical for long-term reliability in harsh conditions.

5. Manufacturing Process and Quality Control

The manufacturing of custom ceramic PCB boards is a highly specialized process, demanding precision at every stage.

Overview of Manufacturing Steps (General for Co-fired Ceramics)

- Powder Preparation & Green Tape Casting: High-purity ceramic powders (alumina, aluminum nitride, or glass-ceramic) are mixed with organic binders and solvents to form a slurry. This slurry is then cast into thin, flexible sheets known as “green tapes” using a doctor blade process. The thickness and consistency of these tapes are precisely controlled.

- Via Punching: Using mechanical punches, lasers, or computer-controlled machines, precise holes (vias) are created in the green tapes according to the ceramic PCB design specifications. These vias will form vertical interconnections between layers.

- Screen Printing/Metallization: Conductive pastes (e.g., tungsten, molybdenum for HTCC; silver, gold for LTCC) are screen-printed onto the green tapes to form circuit traces, pads, and fill vias. This is where the intricate circuitry is laid out on each layer. Dielectric or resistive pastes can also be printed for embedded components.

- Stacking and Lamination: Multiple patterned green tapes are precisely aligned and stacked. The stack is then subjected to high pressure and often elevated temperature in a lamination press. This process bonds the layers together, removing air voids and creating a robust, monolithic structure.

- Co-firing/Sintering: This is the critical step where the laminated stack undergoes a controlled firing process in a high-temperature furnace.

- HTCC: Fired at >1600∘C in a reducing or inert atmosphere. The organic binders burn out, and the ceramic particles sinter (fuse) together, forming a dense, rigid structure, while the refractory metals densify to form conductors.

- LTCC: Fired at 850∘C – 900∘C in an air atmosphere. The glass phase in the ceramic softens, densifies, and then crystallizes, encapsulating the noble metal conductors.

- Post-firing Processes: After firing, the ceramic substrate undergoes various post-processing steps:

- Dicing: The large ceramic panel is precisely cut into individual ceramic PCB units or packages using diamond saws.

- Plating: Electroless or electrolytic plating (e.g., nickel, gold) may be applied to exposed metallization for improved solderability, wire bonding, or corrosion resistance.

- Lapping/Polishing: In some cases, the surface may be lapped or polished for improved flatness and surface finish, especially for thin-film applications.

Key Quality Control Measures

Rigorous quality control is essential throughout the manufacturing process to ensure the high reliability expected of ceramic PCB products.

- Dimensional Accuracy: Optical inspection and precise measurement systems verify layer alignment, via placement, and overall dimensions.

- Electrical Testing: Continuity checks and insulation resistance tests are performed to identify opens, shorts, or leakage currents. High-frequency performance testing (e.g., S-parameter measurements) is conducted for RF applications.

- Thermal Performance Testing: Thermal cycling, power cycling, and thermal resistance measurements assess the PCB’s ability to dissipate heat under operational conditions.

- Microstructural Analysis: Cross-sectional analysis of fired samples helps verify proper sintering, metallization quality, and absence of defects.

- Hermeticity Testing: For sealed packages, leak testing (e.g., fine and gross leak tests) ensures the integrity of the hermetic seal.

6. Common Applications of Ceramic Multilayer PCBs

The unique properties of ceramic PCBs make them indispensable in a wide array of high-reliability and high-performance applications.

- High-Power Electronics: Due to their excellent thermal conductivity, ceramic PCBs are ideal for power modules, high-brightness LEDs, solar cell arrays, motor controllers, and automotive power electronics where efficient heat dissipation is critical for performance and longevity.

- RF and Microwave Modules: The low dielectric loss and stable electrical properties of ceramic materials make them perfect for high-frequency applications like antennas, transceivers, filters, power amplifiers, radar systems, and satellite communication components. LTCC technology is particularly prevalent here due to its ability to integrate high-Q passives and use low-loss conductors.

- Medical Devices: Biocompatibility, hermeticity, and reliability are paramount in medical applications. Ceramic PCBs are found in implantable medical devices (pacemakers, neural implants), diagnostic equipment, medical sensors, and high-precision instruments.

- Aerospace and Defense: Extreme temperatures, vibrations, and radiation are common in aerospace and defense environments. Ceramic PCBs are used in avionics, missile guidance systems, satellite communication modules, military radar, and ruggedized electronic systems due to their high reliability and resistance to harsh conditions.

- Automotive Electronics: Modern vehicles contain numerous electronic systems operating in demanding thermal and vibrational environments. Ceramic PCBs are utilized in engine control units (ECUs), sensor modules (e.g., pressure, temperature, exhaust gas), and power management systems where durability and performance under stress are essential.

- Industrial Control and Sensor Applications: For industrial automation, process control, and sensor systems that operate in high-temperature or corrosive environments, ceramic PCBs provide the necessary stability and long-term reliability.

7. Cost Considerations and ROI

When evaluating a ceramic PCB, the initial ceramic PCB cost can often seem higher than that of an organic PCB. However, a holistic view that includes the total cost of ownership and return on investment (ROI) is crucial.

Factors Influencing Cost

- Material Cost: Ceramic substrates like aluminum nitride are inherently more expensive than FR-4.

- Manufacturing Complexity: The specialized processes (e.g., high-temperature firing, precise green tape handling, noble metal usage) require sophisticated equipment and skilled labor, contributing to higher manufacturing costs.

- Layer Count and Design Complexity: As with any PCB, higher layer counts and more intricate designs increase costs.

- Metallization Type: Using noble metals like gold for LTCC can be more expensive than copper on FR-4, but offers superior electrical performance.

- Volume: Ceramic PCB prototyping and small-batch production typically have a higher per-unit cost than large-scale wholesale ceramic PCB orders, where economies of scale can be realized.

Long-Term Value Proposition and ROI

While the upfront ceramic PCB cost may be higher, the long-term benefits often justify the investment:

- Enhanced Reliability and Durability: Ceramic’s resistance to thermal stress, harsh environments, and chemical degradation leads to significantly fewer field failures and longer product lifespans. This translates to reduced warranty claims, lower repair costs, and improved brand reputation.

- Superior Performance: For high-frequency, high-power, or high-temperature applications, ceramic PCBs enable performance levels that are simply unachievable with organic materials. This can lead to competitive advantages, new product capabilities, and market leadership.

- Reduced Total Cost of Ownership (TCO): When considering the entire lifecycle of a product—from manufacturing to deployment, maintenance, and potential replacement—the higher reliability of ceramic can result in a lower TCO. Fewer replacements, less downtime, and stable performance can lead to significant savings over time.

- Miniaturization and Integration: The ability to achieve higher component density and embed passive components can lead to smaller, lighter products, potentially reducing overall system costs and opening up new form factor possibilities.

For companies requiring custom ceramic PCB solutions, it’s vital to work closely with manufacturers to optimize the ceramic PCB design for cost-effectiveness without compromising critical performance metrics.

8. Future Trends and Innovations

The field of ceramic multilayer PCBs continues to evolve, driven by the relentless demand for higher performance and greater integration.

- Advanced Ceramic Materials: Research is ongoing into novel ceramic compositions with even higher thermal conductivities, lower dielectric constants, and improved mechanical properties. This includes exploration of composite ceramics and new methods for densification.

- Miniaturization and Higher Integration: Expect even finer line/space capabilities and greater integration of active and passive components within the ceramic substrate, leading to true System-in-Package (SiP) solutions based on ceramic. This will simplify ceramic PCB assembly and reduce overall system size.

- Integration with Other Technologies: The future will see more seamless integration of ceramic PCBs with other advanced technologies, such as Micro-Electro-Mechanical Systems (MEMS), photonics, and fluidics, creating highly functional, multi-domain modules.

- Additive Manufacturing for Ceramics: While still in its early stages, additive manufacturing techniques like stereolithography (SLA) or binder jetting for ceramics hold immense promise. These technologies could revolutionize ceramic PCB prototyping by enabling rapid production of complex 3D structures with intricate internal features, opening up possibilities for highly customized and functionally integrated ceramic components that are impossible with traditional methods.

9. Conclusion

Ceramic multilayer PCBs represent a pinnacle of electronic packaging technology, offering unparalleled thermal, electrical, and mechanical performance for the most demanding applications. While the initial ceramic PCB cost might be higher than traditional organic boards, their superior reliability, extended lifespan, and ability to operate in extreme environments often translate into a significantly lower total cost of ownership and a strong return on investment.

For engineers and product developers grappling with thermal dissipation challenges, high-frequency signal integrity issues, or the need for extreme environmental ruggedness, a custom ceramic PCB solution is often the optimal choice. By understanding the different types (HTCC, LTCC), crucial ceramic PCB design considerations, and the intricate manufacturing processes, users can harness the full potential of this advanced technology to create next-generation electronic systems that are more reliable, powerful, and compact than ever before. Whether exploring ceramic PCB prototyping or seeking wholesale ceramic PCB solutions, partnering with experienced manufacturers is key to unlocking the benefits of ceramic technology.