A Rogers PCB is a critical and worthwhile investment for high-frequency, high-speed, and mission-critical applications where signal integrity, reliability, and performance are non-negotiable. While its initial cost is significantly higher than standard FR-4, Rogers material provides superior electrical performance through a stable dielectric constant and extremely low signal loss, preventing costly redesigns, product failures, and performance degradation in demanding electronic systems. The decision to use Rogers is less about expense and more about insuring the functionality of the final product.

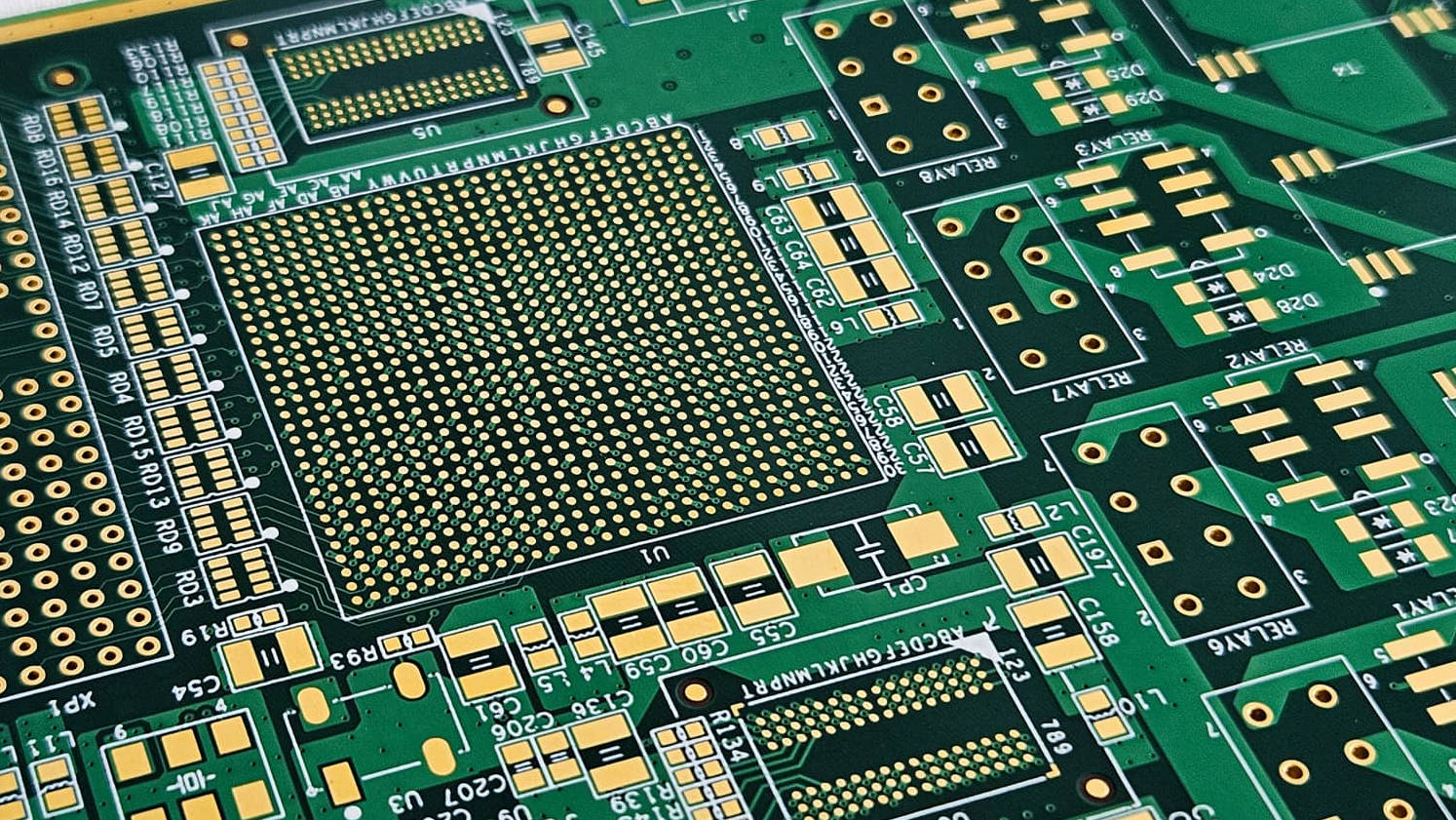

In the world of printed circuit board (PCB) design, material selection is one of the most foundational and impactful decisions an engineer can make. For decades, FR-4 (Flame Retardant 4) has been the go-to, a reliable and cost-effective workhorse for a vast array of electronics. However, as operating frequencies climb into the gigahertz range and data rates soar, the limitations of FR-4 become glaringly apparent. This is where high-performance materials from manufacturers like Rogers Corporation enter the picture. The question that immediately arises for project managers, engineers, and purchasing departments is a crucial one: is the substantial price premium for a Rogers PCB justified? This article provides an in-depth analysis of the cost-versus-performance trade-off, helping you determine when investing in Rogers material is not just a good idea, but an absolute necessity.

Table of Contents

- What Fundamentally Separates Rogers PCBs from Standard FR-4?

- The Core Performance Metrics: Why Do Engineers Choose Rogers?

- The Cost Equation: A Head-to-Head Comparison

- When is a Rogers PCB an Absolute Necessity? (The Decision Checklist)

- Can You Get the Best of Both Worlds? Exploring Hybrid Stack-ups

- The Final Verdict: Is Rogers PCB Worth Your Investment?

- Frequently Asked Questions (FAQ)

What Fundamentally Separates Rogers PCBs from Standard FR-4?

To understand the value proposition of Rogers materials, we first need to appreciate the characteristics and limitations of the industry standard, FR-4. They are fundamentally different materials designed for different operational paradigms.

The Ubiquitous Standard: Understanding FR-4

FR-4 is a composite material composed of woven fiberglass cloth impregnated with an epoxy resin binder. Its popularity stems from a potent combination of good mechanical strength, excellent flame-retardant properties, and a very low price point. For the majority of consumer electronics, computer peripherals, and low-frequency applications, FR-4 performs admirably. However, its electrical properties begin to break down as signal frequencies increase. Its dielectric constant (Dk) can vary significantly with frequency and temperature, and its dissipation factor (Df), or signal loss, is relatively high, making it unsuitable for sensitive, high-performance circuits.

The High-Performance Specialist: Introducing Rogers Materials

Rogers Corporation manufactures a range of high-performance laminates that are not based on simple epoxy/glass composites. Instead, they often use proprietary ceramic-filled PTFE (Polytetrafluoroethylene) composites or hydrocarbon-based thermoset materials. This advanced composition is engineered specifically for superior electrical performance. The key benefit is consistency. Rogers materials exhibit an extremely stable dielectric constant across a wide frequency range and under varying temperatures. Furthermore, their dissipation factor is an order of magnitude lower than FR-4, meaning far less signal energy is lost as it travels through the PCB.

The Core Performance Metrics: Why Do Engineers Choose Rogers?

The decision to invest in Rogers material boils down to four critical performance characteristics where it vastly outperforms FR-4. These metrics directly impact signal integrity, which is the measure of the quality of an electrical signal.

Dielectric Constant (Dk): The Foundation of Signal Speed and Stability

The dielectric constant determines how fast a signal travels through the PCB material and is a critical parameter for impedance calculations. FR-4 has a Dk of around 4.5, but this value can fluctuate by as much as 10% depending on the frequency, temperature, and even the resin content of the specific batch. This instability makes precise impedance matching difficult. Rogers materials, such as the popular RO4350B™, have a tightly controlled Dk (e.g., 3.48 ± 0.05) that remains remarkably stable across gigahertz frequencies. This stability is essential for predictable circuit performance.

Dissipation Factor (Df) / Loss Tangent: Minimizing Signal Energy Loss

The dissipation factor, also known as loss tangent, quantifies how much of the signal’s energy is absorbed and lost as heat within the PCB substrate. FR-4 has a relatively high Df of about 0.020. In contrast, Rogers materials boast much lower Df values, often as low as 0.003 or less. For a high-frequency signal, this difference is profound. A lower Df means a stronger, cleaner signal reaches its destination, which is critical in applications like amplifiers, antennas, and high-speed data links where every decibel of loss matters.

Superior Thermal Management and Stability

High-power and high-frequency circuits generate significant heat. The ability of a PCB to manage this heat is crucial for long-term reliability. Rogers materials often feature a lower Coefficient of Thermal Expansion (CTE) than FR-4, especially in the Z-axis. This means they expand and contract less with temperature changes, reducing stress on plated through-holes and solder joints. This enhanced thermal stability prevents mechanical failures, particularly in devices that experience frequent thermal cycling, such as automotive radar or aerospace electronics.

Unmatched Impedance Control for High-Speed Designs

Controlled impedance is vital for preventing signal reflections and maintaining signal integrity in high-speed digital and RF circuits. Due to the stable Dk and tightly controlled manufacturing tolerances of Rogers laminates, designers can achieve far more precise and reliable impedance control (e.g., 50 ohms for single-ended traces). This predictability simplifies the design process and ensures the circuit performs as simulated, avoiding signal degradation that can cause data errors or complete system failure.

The Cost Equation: A Head-to-Head Comparison

There is no denying the significant price difference. A bare Rogers PCB can cost anywhere from 4 to 20 times more than an equivalent FR-4 board. This cost differential arises from several factors.

Raw Material Price: The Obvious Difference

The advanced polymer and ceramic-filled compositions used in Rogers laminates are intrinsically more expensive to synthesize and produce than the commodity-grade glass and epoxy used for FR-4. The raw material cost is the single largest contributor to the final price of the PCB.

Manufacturing and Fabrication Complexity

Working with Rogers materials requires specialized knowledge and equipment. The PTFE-based materials, for example, are softer and require different drill speeds, feeds, and specialized drill bits to prevent smearing and ensure clean holes for plating. The plasma desmear process, often required for these materials, adds another step and associated cost to the fabrication process. Not all PCB fabricators are equipped or experienced enough to handle these materials, which can also limit supply chain options.

The Hidden Costs of Not Using Rogers: Total Cost of Ownership

Focusing solely on the initial PCB cost is shortsighted. The true cost analysis must include the Total Cost of Ownership (TCO). Consider the following “hidden” costs of choosing an inadequate material like FR-4 for a high-performance application:

- Cost of Redesign: If a prototype built on FR-4 fails due to signal integrity issues, the project incurs significant costs in engineering time, new prototypes, and project delays.

- Cost of Product Failure: For mission-critical systems in aerospace, military, or medical fields, a board failure can have catastrophic consequences that far outweigh the savings on PCB material.

- Cost of Poor Performance: In a competitive market, a product with lower performance (e.g., shorter communication range, slower data rates) is less viable. The investment in Rogers can be a key competitive differentiator.

| Parameter | Standard FR-4 | Rogers (Typical, e.g., RO4000 series) | Why It Matters |

|---|---|---|---|

| Dielectric Constant (Dk) | ~4.2 – 4.8 (Varies with frequency) | ~2.2 – 10.2 (Highly stable with frequency) | Stable Dk is crucial for impedance control and predictable performance. |

| Dissipation Factor (Df) | ~0.020 | ~0.002 – 0.004 | Low Df minimizes signal loss, preserving signal strength and integrity. |

| Operating Frequency | Generally < 3 GHz | Up to 77 GHz and beyond | Defines the suitable application range. |

| Cost Index | 1x (Baseline) | 4x – 20x | Reflects the initial investment required. |

| Thermal Stability (CTE) | Moderate | Excellent | Ensures mechanical reliability under temperature changes. |

When is a Rogers PCB an Absolute Necessity? (The Decision Checklist)

The investment in a Rogers PCB is justified when the application falls into one or more of the following categories, where the limitations of FR-4 present an unacceptable risk to performance and reliability.

High-Frequency RF and Microwave Applications

This is the primary domain for Rogers materials. Any circuit operating above 3-5 GHz will see significant performance degradation on FR-4. Examples include:

- 5G and 6G infrastructure: Base station antennas, power amplifiers, and filters.

- Automotive Radar: 77 GHz collision avoidance and ADAS systems.

- Satellite and Aerospace Communication: Uplink/downlink systems, GPS receivers.

- Phased-array antennas where phase accuracy is critical.

High-Speed Digital Circuits

As data rates exceed 10 Gbps, even digital signals begin to behave like RF signals. The low loss and stable Dk of Rogers materials are essential for maintaining the sharp signal edges and open “eye diagrams” necessary for low bit-error rates in:

- High-performance servers and data centers.

- Advanced networking switches and routers.

- Automated test equipment (ATE).

Environments with Extreme Temperature Fluctuations

In applications where the device must operate reliably from freezing cold to scorching heat, the thermal stability of Rogers materials is a key advantage. The stable Dk prevents performance drift as the temperature changes, and the matched CTE reduces mechanical stress on components and vias. This is crucial for aerospace, military, and downhole oil and gas exploration equipment.

Applications Demanding Minimal Signal Distortion

For sensitive measurement and medical imaging equipment, any distortion or loss added by the PCB can compromise the accuracy of the results. Rogers materials ensure that the signal being measured is a true representation of the input, making them indispensable in laboratory instruments and MRI systems.

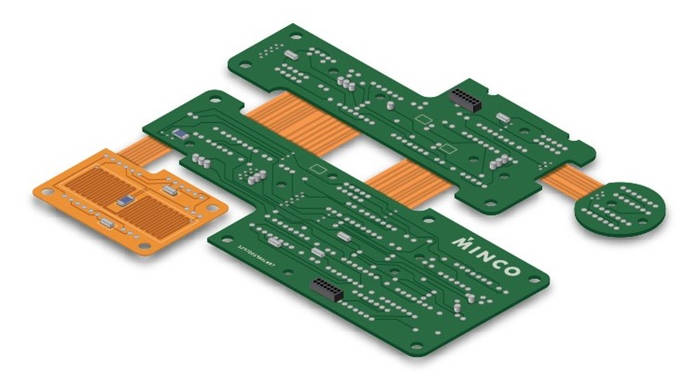

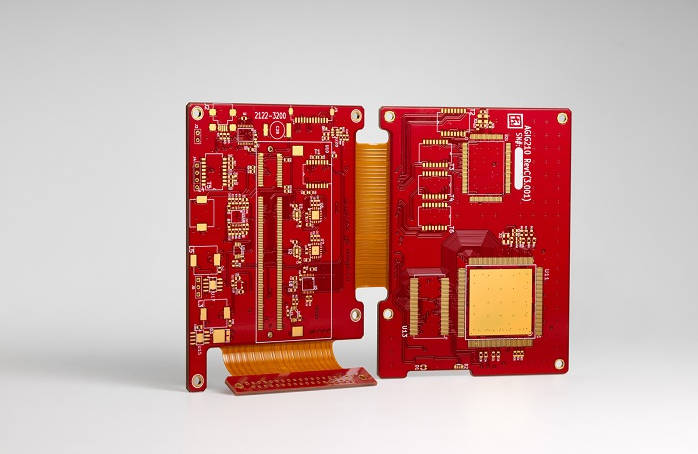

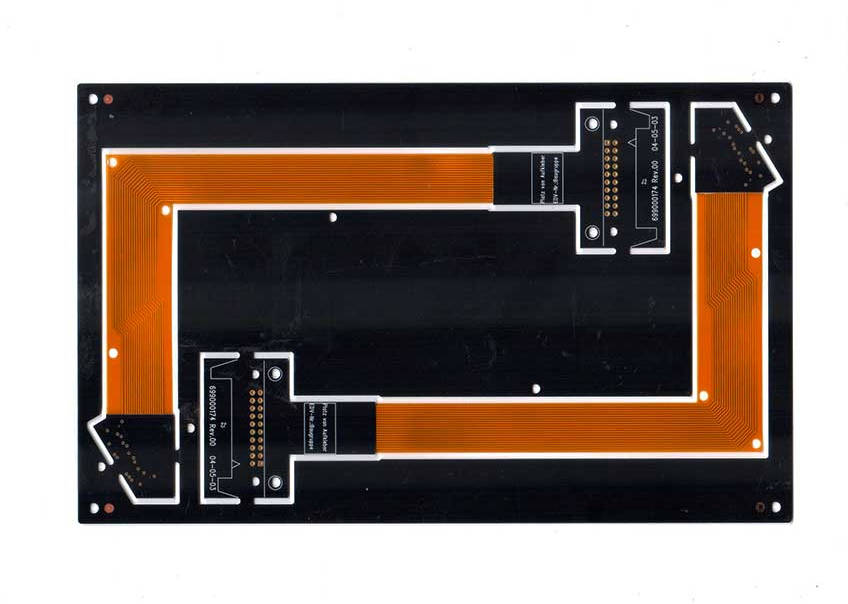

Can You Get the Best of Both Worlds? Exploring Hybrid Stack-ups

For many complex designs, not all layers require high-performance materials. A common cost-saving strategy is to use a hybrid or mixed-material PCB stack-up.

What is a Hybrid PCB Stack-up?

A hybrid stack-up involves using different materials for different layers within the same PCB. For example, the outer layers handling the high-frequency RF signals might be made from a Rogers laminate, while the inner layers responsible for power distribution and low-speed control signals can be made from standard FR-4. These layers are then bonded together into a single, cohesive board.

The Strategic Advantage: Balancing Cost and Performance

This approach provides a powerful compromise. It places the expensive, high-performance material only where it is electrically necessary, significantly reducing the overall material cost of the board. However, hybrid stack-ups introduce their own fabrication challenges, such as bonding dissimilar materials with different CTEs. It’s crucial to work with a PCB fabricator that has proven expertise and experience in manufacturing these complex mixed-dielectric boards.

The Final Verdict: Is Rogers PCB Worth Your Investment?

So, we return to the central question: is a Rogers PCB worth the investment? The answer is an unequivocal yes, when the application demands it. For any project operating in the high-frequency or high-speed domain, trying to “save money” by using FR-4 is a false economy. The potential costs of poor performance, signal failure, extensive troubleshooting, and product redesigns will invariably dwarf the initial savings on the bare board.

Think of it not as buying a more expensive PCB, but as investing in performance insurance. Rogers materials provide the predictability, stability, and signal integrity necessary for modern electronics to function reliably at their limits. When your design’s success hinges on a clean, strong signal, the investment in a high-performance substrate like Rogers isn’t a luxury—it’s a fundamental requirement for success.

Frequently Asked Questions (FAQ)

Q1: How much more expensive is Rogers than FR-4?

The cost can vary widely based on the specific Rogers material series, panel utilization, and board complexity. As a general rule, expect a Rogers PCB to cost anywhere from 4 to 20 times more than an FR-4 board of the same size and layer count.

Q2: Can I use FR-4 for high-frequency prototypes to save money?

While tempting, it is generally not recommended. A prototype built on FR-4 will not accurately represent the performance of the final product built on Rogers. The impedance, signal loss, and timing will be completely different, making the prototype data unreliable for design validation. It can lead to false passes or failures, wasting valuable engineering time.

Q3: What are the main series of Rogers materials?

Rogers offers a wide range of materials tailored for different applications. Some of the most common series include the RO4000® Series (e.g., RO4350B™, RO4003C™), which are hydrocarbon ceramic laminates known for easy processing similar to FR-4, and the RT/duroid® Series (e.g., RT/duroid 5880), which are PTFE composites offering extremely low loss for the most demanding microwave and millimeter-wave applications.

Rogers PCB, FR-4, PCB Cost, High-Frequency PCB, PCB Performance, Rogers vs FR-4, Is Rogers PCB Worth It, Signal Integrity, PCB Material, Dielectric Constant, Dissipation Factor, High-Speed Digital PCB, RF PCB Material, Hybrid PCB Stack-up, Cost-Performance Analysis PCB