1. Introduction: Understanding PCB Substrates and Why Your Choice Matters

At the heart of every electronic device lies a Printed Circuit Board (PCB), the foundational component that electrically connects and mechanically supports electronic components. But what’s often overlooked is the material underneath those shining traces and components – the PCB substrate. This base material isn’t just a passive support; it’s a critical element that significantly influences the performance, reliability, and cost of your final product. Choosing the right substrate is paramount, as it directly impacts everything from signal integrity in high-speed applications to the product’s lifespan in harsh environments.

While various FR-grades exist, FR-4 stands out as the industry standard for its superior balance of performance and cost, making it the preferred choice for a vast majority of modern electronic designs. For anyone involved in electronics manufacturing, especially those looking for a reliable and versatile solution, understanding FR-4 is essential. This article will delve into the distinctions between FR-1, FR-2, FR-3, and specifically highlight why FR-4 has become the go-to material for a wide array of applications.

2. A Quick Look at Early FR-Grades: FR-1, FR-2, and FR-3

Before we explore the dominance of FR-4, it’s helpful to understand its predecessors. These earlier FR-grades laid the groundwork but came with significant limitations, restricting their use in today’s demanding electronic landscape.

FR-1 and FR-2 (Phenolic Paper)

- Brief Description: These materials consist of paper impregnated with phenolic resin. They represent some of the earliest forms of PCB substrates.

- Key Characteristics:

- Low Cost: They were extremely inexpensive to produce.

- Good Electrical Insulation: Provided basic isolation between conductors.

- Punchable: Could be fabricated using simple punching methods, reducing manufacturing complexity.

- Limitations:

- Poor Moisture Resistance: Highly susceptible to absorbing moisture, leading to performance degradation and even delamination.

- Lower Temperature Resistance: Limited thermal stability, making them unsuitable for processes like reflow soldering.

- Not Suitable for High-Frequency or Complex Circuits: Their electrical properties were too unstable for advanced designs.

- Typical Applications (Historical/Niche): Due to their limitations, FR-1 and FR-2 are rarely used in modern electronics. Historically, they were found in very simple, single-sided consumer electronics like remote controls, toys, or basic calculators where cost was the absolute primary driver and performance demands were minimal.

FR-3 (Cotton Paper and Epoxy)

- Brief Description: FR-3 was an evolution, combining cotton paper with epoxy resin. The introduction of epoxy was a significant improvement.

- Key Characteristics:

- Improved Electrical Properties: Better dielectric constant (ϵr) and dissipation factor (tan δ) compared to phenolic resins.

- Enhanced Moisture Resistance: Epoxy resin offered superior protection against humidity.

- Limitations:

- Still not ideal for demanding applications requiring high mechanical strength or thermal robustness.

- The paper core still limited its overall performance compared to glass-reinforced materials.

- Typical Applications: FR-3 found its place in slightly more complex, often double-sided, consumer electronics where some performance improvement over FR-1/FR-2 was needed, but the cost was still a major concern.

3. Deep Dive into FR-4: The Industry Workhorse

The acronym FR-4 stands for “Flame Retardant 4.” It is by far the most common and widely used material for Printed Circuit Boards today.

What is FR-4?

FR-4 is a composite material made from woven fiberglass fabric impregnated with epoxy resin, then pressed under heat and pressure to form a rigid laminate. The “FR” indicates that the material is flame retardant, meeting the UL 94V-0 safety standard. This means it self-extinguishes within a specified time when exposed to fire, a critical safety feature.

Key Characteristics and Advantages of FR-4

The widespread adoption of FR-4 stems from its balanced and robust properties, making it suitable for an incredibly diverse range of applications.

| Characteristic | Description | Impact on PCB Performance/Reliability |

| Excellent Electrical Properties | High dielectric strength (insulation capacity), stable dielectric constant (ϵr), and low dissipation factor (tan δ) across a wide frequency range. These properties are crucial for maintaining signal integrity and minimizing signal loss, especially in high-frequency applications. FR-4 typically has a ϵr between 4.3 and 4.7 at 1 GHz, which can vary slightly depending on the resin system. | Ensures clear signal transmission with minimal distortion and loss, vital for high-speed digital circuits and analog RF applications. Stable electrical properties prevent performance fluctuations. This is a key reason why FR4 PCB fabrication is so prevalent. |

| Superior Mechanical Strength | FR-4 boasts high flexural strength, rigidity, and excellent dimensional stability. The woven fiberglass provides significant structural integrity. | Prevents warpage and bending, maintaining precise component alignment and layer registration, especially important for multilayer FR4 PCB designs. Reduces the risk of board damage during assembly, shipping, and in demanding operational environments. |

| Good Thermal Performance | It has a high Glass Transition Temperature (Tg), typically ranging from 130°C to 180°C (standard is ~130°C). Tg is the temperature at which the epoxy resin transitions from a rigid, glassy state to a softer, rubbery state. It also offers good thermal conductivity for effective heat dissipation. | Ensures the PCB maintains its structural integrity and electrical properties during soldering processes (e.g., reflow soldering) and under operational heat loads. A higher Tg means the board can withstand higher temperatures before softening, which is critical for reliability. This makes FR4 PCB manufacturing highly reliable. |

| Moisture Resistance | FR-4 exhibits low water absorption, thanks to the epoxy resin. | Prevents delamination and electrical degradation when the PCB is exposed to humid environments, ensuring long-term reliability and preventing short circuits or performance drops due to moisture absorption. |

| Chemical Resistance | Good resistance to common chemicals used in PCB manufacturing processes (e.g., etching solutions, cleaning agents) and typical operating environments. | Ensures board integrity throughout the FR4 PCB assembly process and during its operational life, even when exposed to various substances. |

| Versatility | Suitable for single-sided, double-sided, and highly complex multilayer FR4 PCB designs. Its material properties allow for very fine trace and space capabilities. | Accommodates a vast range of electronic designs, from simple power boards to complex high-density interconnect (HDI) boards, making it the most versatile choice for a custom FR4 PCB. |

| Cost-Effectiveness | While not the cheapest material, FR-4 offers the best balance of performance for the cost, making it highly accessible and widely adopted. The widespread FR4 PCB manufacturing infrastructure drives competitive pricing. | Provides an optimal solution for budget-conscious projects that still demand high reliability and performance, giving an excellent return on investment in terms of board longevity and functionality. This is a major factor in the widespread availability of a competitive FR4 PCB price. |

| Processability | Compatible with standard PCB manufacturing processes, including drilling, etching, plating, and laminating. | Facilitates efficient and high-yield production, reducing lead times and costs. This is why most FR4 PCB manufacturers are well-equipped to handle complex designs. FR4 PCB fabrication processes are highly mature. |

Common Applications of FR-4

The ubiquity of FR-4 is evident in its applications across almost every sector of the electronics industry:

- Computers and Peripherals: Motherboards, graphics cards, network cards.

- Telecommunications Equipment: Routers, switches, base stations.

- Industrial Control Systems: PLCs, factory automation equipment.

- Automotive Electronics: Engine control units (ECUs), infotainment systems (where extreme temperatures aren’t a constant).

- Consumer Electronics: Smartphones, tablets, televisions, home appliances.

- Medical Devices: Diagnostic equipment, monitoring systems.

4. Why FR-4 is the Preferred Choice for Most Modern Applications

For users requiring new PCBs, FR-4 consistently emerges as the most practical and efficient solution for several compelling reasons:

- Reliability: The robust physical and electrical properties of FR-4 contribute directly to the long-term reliability and stable performance of electronic devices. Its resistance to moisture, temperature fluctuations, and mechanical stress means less risk of component failure or board damage over time. When you choose an FR4 PCB, you’re investing in a proven, stable foundation for your electronics.

- Performance: FR-4’s stable dielectric constant and low dissipation factor support increasingly higher operating frequencies and faster signal transmission. This is crucial for maintaining signal integrity in today’s high-speed digital circuits. Whether you’re designing for IoT, AI, or advanced computing, FR4 PCB design principles are well-established to handle demanding performance requirements.

- Manufacturing Ease & Cost: Because FR-4 is the industry standard, the entire ecosystem around its manufacturing is highly optimized. FR4 PCB manufacturers worldwide possess extensive expertise and equipment specifically calibrated for FR-4. This leads to efficient FR4 PCB fabrication processes, competitive FR4 PCB price points, and reliable FR4 PCB assembly. The widespread availability of materials and established production lines means faster turnaround times and greater cost predictability for custom FR4 PCB orders.

- Meeting Industry Standards: FR-4’s compliance with critical safety and performance standards, particularly its UL 94V-0 flame retardancy, ensures that products meet necessary regulatory requirements for consumer safety and market entry.

5. When to Consider Alternatives (Briefly, for Context)

While FR-4 is exceptionally versatile, there are niche applications where its properties might not be optimal. In such cases, specialized materials come into play:

- Extremely High-Frequency/RF Applications (e.g., Millimeter Wave, 5G): Materials like PTFE (Teflon) or ceramic-filled laminates (e.g., Rogers Corporation’s materials) offer significantly lower dielectric loss (tan δ) and more stable dielectric constants, critical for maintaining signal integrity at very high frequencies.

- Extreme High-Temperature Environments: For applications continuously exposed to temperatures well above FR-4’s Tg, materials like polyimide or specialized high-Tg epoxies are used.

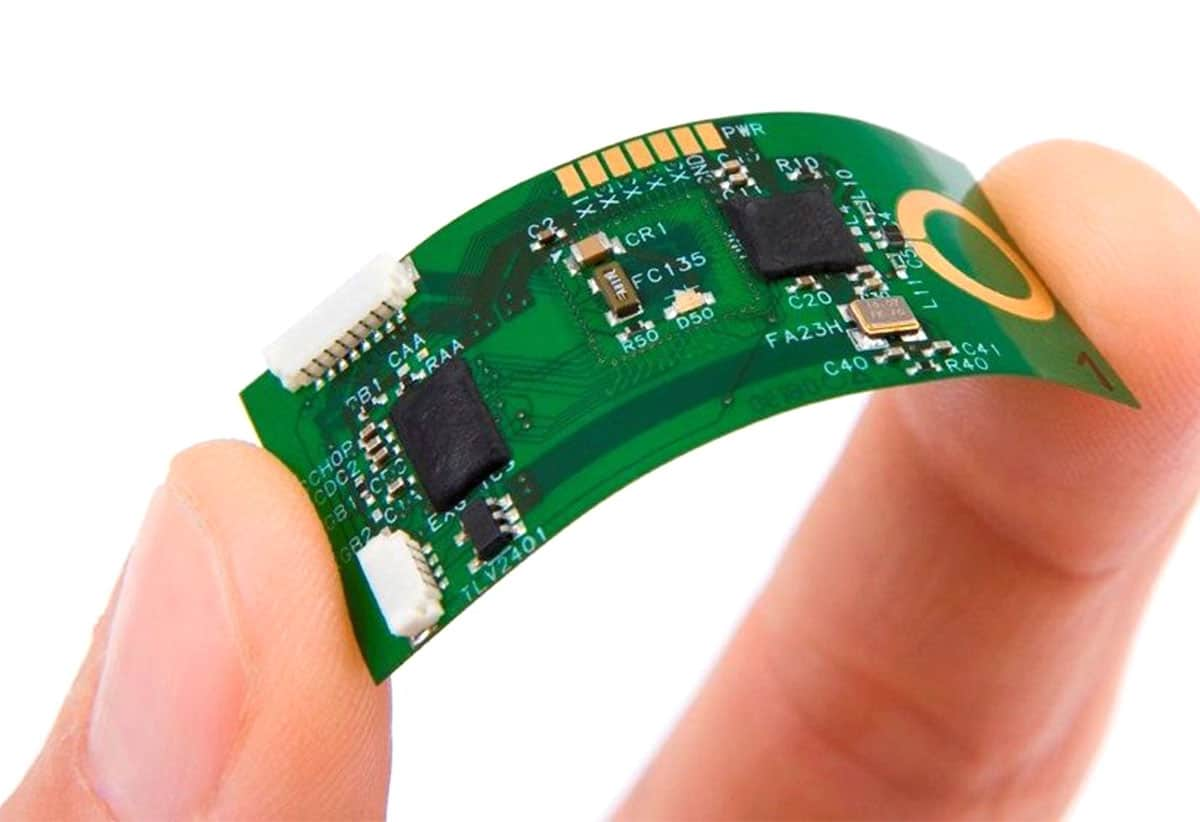

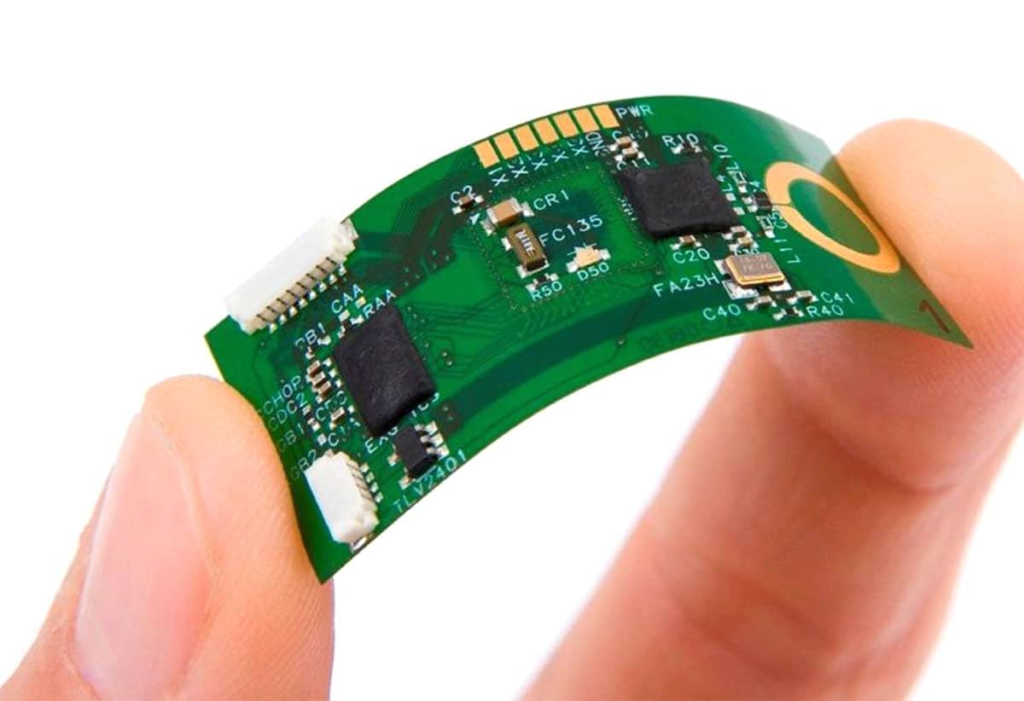

- Flexible Electronics: For circuits designed to bend or flex repeatedly, polyimide films (e.g., Kapton) are the material of choice for flexible PCBs.

- Extreme Thermal Management: For high-power applications generating significant heat, metal-core PCBs (e.g., aluminum core) are employed to efficiently dissipate heat away from components.

Key Takeaway: For the vast majority of applications, from consumer gadgets to industrial controls and telecommunications infrastructure, FR-4 provides an excellent balance of performance, reliability, and cost-effectiveness, making it the default and most robust recommendation.

6. Conclusion: The Enduring Legacy of FR-4

In the complex world of electronics, the choice of PCB substrate is foundational. While earlier FR-grades like FR-1, FR-2, and FR-3 served their purpose, their limitations quickly became apparent with the increasing demands of modern technology. FR-4 emerged as the quintessential material, offering an unmatched combination of electrical performance, mechanical strength, thermal stability, and cost-effectiveness.

For any electronic designer or product developer, understanding the advantages of FR-4 is crucial. When seeking a reliable FR4 PCB manufacturer for your next project, you’re tapping into a mature industry with established processes for FR4 PCB design, fabrication, assembly, and manufacturing. Its enduring legacy is a testament to its versatility and ability to meet the stringent requirements of today’s diverse electronic landscape. For users needing reliable, high-performance, and cost-effective PCBs, FR-4 remains the most robust and versatile choice.