The primary difference between an HDI (High-Density Interconnect) PCB and a standard PCB lies in their circuit density and manufacturing complexity. HDI PCBs utilize advanced technologies like microvias, finer traces and spaces, and sequential lamination to pack more functionality into a smaller area, enabling device miniaturization and superior electrical performance. In contrast, standard PCBs rely on traditional through-hole vias and have lower component and routing density, making them suitable for less complex, larger-scale electronics. This article provides an in-depth comparison, exploring the core technologies, key advantages, and critical decision-making factors to help you choose the right board for your next project.

Table of Contents

- What is a Standard PCB? The Foundation of Electronics

- What is an HDI PCB? Pushing the Boundaries of Miniaturization

- Key Differences: A Head-to-Head Comparison

- Comparison Table: HDI PCB vs. Standard PCB at a Glance

- When Should You Choose an HDI PCB? A Decision-Making Guide

- The Future is Dense: The Growing Importance of HDI

What is a Standard PCB? The Foundation of Electronics

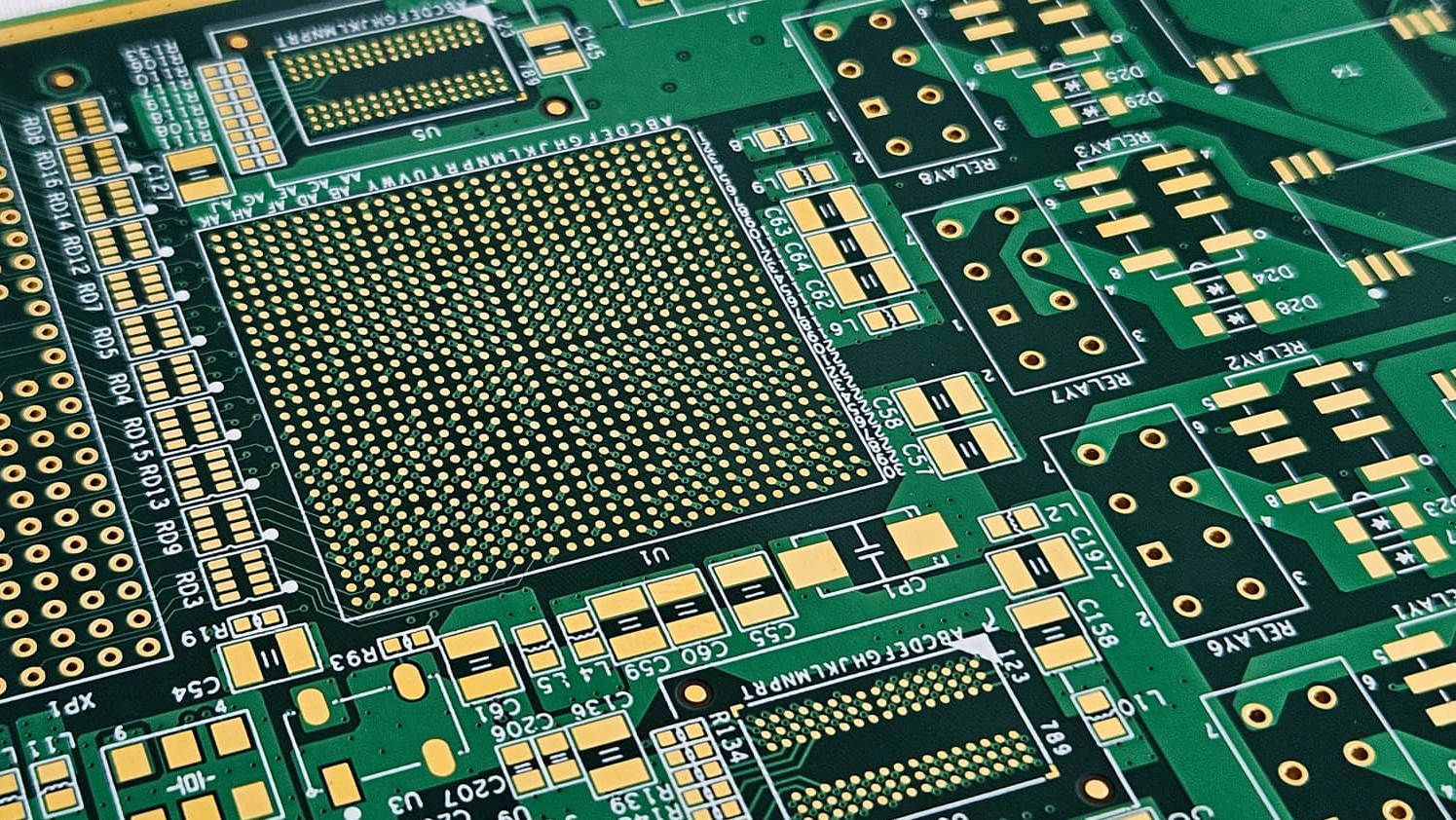

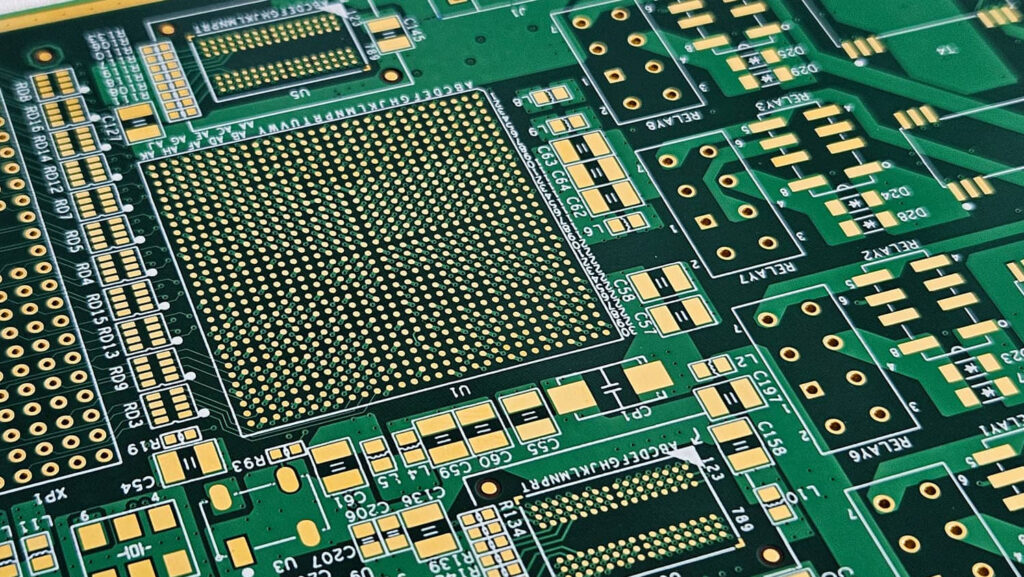

A standard Printed Circuit Board (PCB), often called a conventional PCB, is the workhorse of the electronics industry. It serves as the foundational platform for mounting and interconnecting electronic components in countless devices. These boards are defined by their relatively straightforward manufacturing processes and less dense design rules, making them a cost-effective and reliable solution for a wide range of applications.

Core Construction and Characteristics

The construction of a standard PCB primarily involves a subtractive manufacturing method, where copper is etched away from a laminate substrate to create the desired conductive traces. The most defining feature of a standard board is its reliance on mechanically drilled Plated Through-Holes (PTHs) to connect different layers. These vias pass through the entire thickness of the board, from the top to the bottom layer, regardless of which internal layers they need to connect. This approach, while simple and robust, creates significant limitations. Because a PTH occupies space on every layer it passes through, it restricts the available area for component placement and signal routing, especially in multi-layer designs.

Typically, design rules for standard PCBs feature wider trace and space widths, generally greater than 4 mils (0.1mm). This makes them easier to manufacture with high yields but inherently limits the overall circuit density. Consequently, achieving complex functionality often requires increasing the board’s physical size or adding more layers, which can lead to bulkier end products.

Common Applications and Use Cases

The simplicity and cost-effectiveness of standard PCBs make them the ideal choice for applications where space is not a primary constraint and electrical performance demands are moderate. You will find standard PCBs in a vast array of products, including:

- Desktop computer motherboards and peripherals

- Power supplies and converters

- Industrial control systems and machinery

- Large consumer electronics like televisions and home appliances

- Automotive electronics that do not require extreme miniaturization

- Simple electronic toys and gadgets

What is an HDI PCB? Pushing the Boundaries of Miniaturization

High-Density Interconnect (HDI) represents a significant evolution in PCB technology, specifically engineered to address the relentless demand for smaller, lighter, and more powerful electronic devices. An HDI PCB is defined by its ability to achieve a much higher wiring and component density per unit area compared to its standard counterpart. This is accomplished through a suite of advanced manufacturing techniques that fundamentally change how circuits are designed and fabricated.

The Technology Behind High-Density Interconnect

The magic of HDI lies in its specialized features and processes. Rather than relying on bulky through-holes, HDI technology employs sophisticated interconnects and build-up methods to maximize real estate.

- Key Feature: Microvias. This is the cornerstone of HDI technology. Microvias are tiny, laser-drilled holes, typically with a diameter of 150 microns or less, that connect adjacent layers. Unlike through-holes, they do not need to penetrate the entire board. This enables several types of advanced vias:

- Blind Vias: Connect an outer layer to one or more inner layers without passing through the entire board.

- Buried Vias: Connect two or more inner layers without extending to either outer layer.

- Stacked/Staggered Microvias: Multiple microvias can be stacked on top of each other or staggered across layers to create complex interconnections.

- Key Process: Sequential Lamination. Standard multi-layer boards are typically laminated in a single pressing operation. In contrast, HDI boards are built using a Sequential Build-Up (SBU) process. Layers are added in pairs, one at a time, followed by laser drilling, plating, and etching. This iterative process allows for the creation of the complex blind and buried via structures that are impossible to achieve with standard methods.

- Key Benefit: Finer Lines and Spaces. The precision of HDI manufacturing allows for significantly narrower trace widths and tighter spacing between them, often falling below 4 mils (0.1mm). This drastically increases the routing capacity of each layer, allowing designers to route complex signals without needing to expand the board size or layer count.

Advanced HDI Structures (e.g., Any-Layer HDI)

The pinnacle of HDI technology is the “Any-Layer” or Every Layer Interconnect (ELIC) structure. In these highly advanced boards, each layer is a microvia layer, allowing connections to be made between any two layers in the stack-up with maximum flexibility. This technology is crucial for the ultra-compact designs found in high-end smartphones and other premium handheld devices, where every micron of space is critical.

Key Differences: A Head-to-Head Comparison

Understanding the fundamental distinctions between HDI and standard PCBs is crucial for making informed design and engineering decisions. The differences span everything from the physical construction to electrical performance and overall system cost.

Via Technology: Through-Holes vs. Microvias

The most significant differentiator is the via technology. A standard through-hole acts like a building-wide elevator shaft, occupying a fixed space on every single floor, even the ones it doesn’t stop at. This “via stub” creates unwanted capacitance and inductance, which can degrade high-speed signals. More importantly, it creates a “keep-out” zone on every layer, preventing traces from being routed through that area. In contrast, microvias are like express elevators that only travel between the specific floors (layers) that need to be connected. This targeted approach frees up immense amounts of routing space on unused layers, a concept known as “via-in-pad” design, where microvias can be placed directly on component pads, further densifying the layout.

Density and Miniaturization

The use of microvias and finer traces directly translates to a massive increase in density. HDI technology allows designers to use smaller, more advanced component packages, such as fine-pitch Ball Grid Arrays (BGAs) with pitches below 0.5mm, which are nearly impossible to route on a standard PCB. By placing components closer together and routing more traces between them, HDI can achieve the same electrical functionality of a large, 12-layer standard board in a smaller, 8-layer HDI board. This reduction in both size and layer count is the primary driver for miniaturization in modern electronics.

Electrical Performance and Signal Integrity

HDI offers substantial performance benefits, especially for high-frequency applications. The shorter signal paths created by microvias reduce signal travel time and minimize performance-degrading parasitics like unwanted capacitance and inductance. This leads to cleaner signals with better integrity. Furthermore, the compact design allows for more solid and contiguous ground planes, which is critical for providing a stable return path for signals and improving power integrity. The smaller current loops inherent in dense HDI layouts also lead to a significant reduction in Electromagnetic Interference (EMI) emissions, making it easier to pass regulatory compliance tests.

Manufacturing Process and Complexity

The manufacturing processes for these two types of boards are worlds apart. Standard PCBs use well-established, high-volume processes involving mechanical drilling and single-step lamination. This makes them relatively simple and quick to produce. HDI manufacturing, however, is a far more intricate and capital-intensive affair. It requires specialized equipment like CO2 or UV laser drills for microvias, advanced imaging systems for fine lines, and a multi-step sequential lamination process. Each lamination cycle adds time, complexity, and potential points of failure, requiring stringent process control and advanced quality assurance.

Cost Implications: Initial vs. System-Level

At first glance, an HDI PCB is more expensive to fabricate on a per-board basis than a standard PCB of the same size. The advanced processes, specialized equipment, and tighter tolerances naturally command a higher price. However, this view can be misleading. It is crucial to consider the total system-level cost. By enabling a smaller form factor, an HDI board can lead to savings on the product’s enclosure and other mechanical parts. By reducing the layer count needed for a complex design (e.g., moving from a 12-layer standard board to an 8-layer HDI board), the cost difference can narrow or even reverse. Furthermore, improved electrical performance can eliminate the need for costly signal conditioning components, leading to a lower Bill of Materials (BOM).

Comparison Table: HDI PCB vs. Standard PCB at a Glance

| Feature | Standard PCB | HDI PCB |

|---|---|---|

| Via Type | Plated Through-Holes (PTH), mechanically drilled. | Microvias (Blind, Buried, Stacked), laser-drilled. |

| Line/Space Width | Typically ≥ 4 mils (0.1mm) | Typically ≤ 4 mils (0.1mm), often much finer. |

| Component Density | Low to medium. Limited by through-hole pads. | High to very high. Enables fine-pitch BGAs. |

| Layer Count Reduction | Higher layer counts needed for complex designs. | Can achieve the same routing in fewer layers. |

| Manufacturing Process | Single lamination cycle, subtractive etching. | Sequential Build-Up (SBU), multiple lamination cycles. |

| Cost per Board | Lower | Higher |

| Electrical Performance | Good for low-to-mid frequency. Prone to EMI. | Excellent for high-speed signals. Better signal integrity and EMI control. |

| Typical Applications | Power supplies, industrial controllers, desktop PCs. | Smartphones, wearables, medical devices, aerospace. |

When Should You Choose an HDI PCB? A Decision-Making Guide

Choosing between a standard and an HDI PCB is not a matter of which is “better,” but which is appropriate for the specific demands of your product. The decision hinges on a careful balance of performance requirements, physical constraints, and budget.

Scenarios Demanding HDI Technology

Opt for HDI technology when your design faces one or more of the following challenges:

- Miniaturization is Critical: If your product is a smartphone, wearable, IoT sensor, or medical implant, size and weight are non-negotiable constraints. HDI is the enabling technology for creating compact, feature-rich devices.

- High-Speed Signal Requirements: For designs incorporating fast digital circuits, such as DDR4/5 memory interfaces, high-speed SerDes, or powerful processors, signal integrity is paramount. The shorter stubs and controlled impedance of HDI routing are essential for maintaining signal quality and preventing data errors.

- Complex, High Pin-Count Components: When your design is built around fine-pitch Ball Grid Arrays (BGAs) or other high-density packages, standard through-hole routing is often physically impossible. HDI’s via-in-pad capability is necessary to “escape” the dense pin fields of these modern components.

- Reducing Layer Count is a Goal: If a standard design approach results in a thick, complex, and expensive board with a high layer count (e.g., 16+ layers), it’s worth re-evaluating with an HDI structure. It’s often possible to achieve the same routing in fewer layers, which can improve manufacturability and potentially reduce cost.

When a Standard PCB is the Right Choice

Despite the advanced capabilities of HDI, the standard PCB remains the most practical and economical choice for a huge number of projects. Stick with a standard board when:

- The project is highly cost-sensitive and has ample physical space. For products where the final form factor is flexible and minimizing part cost is the top priority, standard PCBs are unbeatable.

- The design primarily uses larger, through-hole components or wide-pitch surface-mount devices. These components do not require the density offered by HDI.

- The circuits are low-frequency analog or simple digital logic. If signal integrity concerns are minimal, the added performance benefits and cost of HDI are unnecessary.

- You are in the early stages of prototyping. Standard PCBs are faster and cheaper to fabricate in small quantities, making them ideal for initial proof-of-concept models where design rules can be relaxed.

The Future is Dense: The Growing Importance of HDI

In summary, the choice between HDI and standard PCBs is a strategic engineering decision. Standard PCBs offer a reliable, cost-effective foundation for a vast range of conventional electronics, while HDI provides the advanced capabilities needed for miniaturization and high-performance applications. HDI is not merely an incremental improvement; it is a fundamentally different technology designed to solve a different class of problems.

As industry trends like 5G, the Internet of Things (IoT), artificial intelligence hardware, and autonomous vehicles continue to push for more computational power in smaller packages, the adoption of HDI technology will only accelerate. For modern hardware engineers and product designers, understanding the distinct advantages and trade-offs of both standard and high-density interconnect technologies is no longer optional—it is a critical skill for creating the innovative products of tomorrow.

HDI PCB, Standard PCB, HDI PCB vs Standard PCB, High-Density Interconnect, PCB Technology, Microvias, PCB Design, Difference between HDI and standard PCB, Sequential Lamination, When to use HDI PCB