In the rapidly evolving landscape of electronics manufacturing, the transition from MegaHertz (MHz) to GigaHertz (GHz) represents more than just a speed upgrade—it is a fundamental shift in physics. As we push into the realms of 5G, automotive radar, and high-speed networking, the printed circuit board (PCB) is no longer merely a mechanical carrier for components. It has become an active circuit element.

For engineers designing high-speed digital (HSD) or radio frequency (RF) systems, the choice of substrate material is the single most critical decision in the stack-up process. The standard FR-4 that has served the industry for decades is effectively a “signal sponge” at high frequencies. To maintain Signal Integrity (SI), designers must navigate a complex market of advanced materials.

This comprehensive guide provides an in-depth comparison of the industry’s leading high-speed materials—from Rogers and Panasonic to Isola. We will dissect the physics of dielectric loss, analyze the manufacturing challenges of hybrid stack-ups, and declare the winners for specific GHz applications.

I. The Physics of Loss: Why FR-4 Fails at GHz

To understand why advanced materials are necessary, we must first understand the enemy: Insertion Loss. When a high-frequency signal travels through a PCB trace, it loses energy. This loss comes from two primary sources, and the choice of material dictates both.

1. Dielectric Loss (The Material Factor)

Dielectric loss occurs because the insulating material between the copper layers absorbs energy from the alternating electric field. This is measured by the Dissipation Factor (Df) or Loss Tangent ($\tan \delta$).

- The Mechanism: In standard FR-4, the polar molecules in the epoxy resin try to align themselves with the oscillating high-frequency field. As they rotate, they generate heat. This heat is literally your signal energy being cooked away.

- The Frequency Impact: Dielectric loss increases linearly with frequency. An FR-4 board that works perfectly at 100 MHz becomes a black hole for signals at 10 GHz.

- Featured Snippet: For high-speed designs operating above 1 GHz, standard FR-4 (Df ~0.020) causes excessive signal attenuation. Engineers must switch to “Low Loss” materials (Df < 0.005) or “Ultra-Low Loss” materials (Df < 0.003) to preserve signal integrity.

2. Conductor Loss (The Copper Factor)

While this article focuses on the dielectric, the material choice also impacts conductor loss. High-frequency signals travel on the skin of the copper conductor (Skin Effect).

- Surface Roughness: If the copper surface is rough (to help it stick to the dielectric), the signal has to travel a longer path over the “peaks and valleys” of the copper tooth.

- The Material Connection: High-performance materials like Rogers RO4350B or Megtron 6 are often paired with Hyper-Very Low Profile (HVLP) copper foil to minimize this effect. Standard FR-4 relies on rougher copper for mechanical adhesion, further degrading high-speed performance.

II. The Critical Scorecard: Key Material Parameters

When reading a laminate datasheet, three parameters define whether a material is suitable for your GHz application.

1. Dielectric Constant (Dk / $\epsilon_r$): Speed and Stability

The Dk value determines the speed of signal propagation ($V_p$).

- Lower Dk = Faster Speed: A lower Dk allows signals to travel faster, reducing propagation delay—critical for high-speed digital buses like DDR5 or PCIe Gen 5.

- Dk Stability: This is arguably more important than the absolute value.

- Dk vs. Frequency: Does the Dk change as you move from 1 GHz to 50 GHz? If it drops significantly, it causes broadband signal distortion.

- Dk vs. Temperature: As the device heats up, does the Dk shift? This is vital for phase-sensitive applications like Phased Array Radars.

2. Dissipation Factor (Df): The Loss Metric

As mentioned, this measures how “lossy” the material is.

- Standard Loss (FR-4): 0.015 ~ 0.025

- Mid Loss (Isola 370HR): 0.010 ~ 0.015

- Low Loss (Rogers 4350B): 0.003 ~ 0.004

- Ultra-Low Loss (Rogers 3003 / Megtron 7): < 0.002

3. Thermal Reliability (Tg, Td, and CTE)

High-speed materials must also survive the manufacturing process and harsh operating environments.

- Tg (Glass Transition Temperature): The point where the rigid material becomes soft. For lead-free soldering reliability, a Tg > 170°C is preferred.

- CTE (Coefficient of Thermal Expansion): How much the material expands under heat. A low Z-axis CTE is crucial to prevent plated through-holes (vias) from cracking during reflow.

III. The Contenders: A Deep Dive into Market Leaders

We will categorize the materials into four distinct tiers, analyzing the most popular options in the industry.

Tier 1: High-Performance Epoxy (The “Better” FR-4)

- Representative: Isola 370HR

- Composition: Modified Epoxy with high-performance fillers.

- Performance Profile:

- Dk: ~4.0

- Df: ~0.016

- Analysis: Isola 370HR is the workhorse of the “high-reliability” world. It has excellent thermal properties (high Tg), making it great for automotive under-the-hood applications or industrial controllers. However, electrically, it is still an epoxy system. It is not suitable for long-trace GHz signals, but it serves as an excellent, cost-effective “core” material in hybrid stack-ups.

Tier 2: Low-Loss Thermoset (The Digital King)

- Representative: Panasonic Megtron 6 / Megtron 7

- Composition: Polyphenylene Ether (PPE) or Polyphenylene Oxide (PPO) resin blends.

- Performance Profile:

- Dk: 3.4 ~ 3.7

- Df: 0.002 ~ 0.004

- Analysis: Panasonic Megtron 6 is the industry standard for High-Speed Digital (HSD) applications. Whether it’s a supercomputer motherboard, a network switch, or a high-end server, you will likely find Megtron inside.

- Why it wins: It offers “PTFE-like” electrical performance but processes like a standard FR-4 board. It can be laminated into high-layer-count boards (20+ layers) without the mechanical drift issues associated with Teflon.

Tier 3: Hydrocarbon Ceramic (The RF Standard)

- Representative: Rogers RO4000 Series (RO4350B, RO4003C)

- Composition: Hydrocarbon resin reinforced with ceramic filler and woven glass.

- Performance Profile:

- Dk: 3.38 (RO4003C) / 3.48 (RO4350B)

- Df: 0.0027 (RO4003C) / 0.0037 (RO4350B)

- Analysis: Rogers RO4350B is the most famous material in the RF world. Unlike PTFE, it is rigid. This means it can be handled by standard pick-and-place machines and processed in standard PCB fab lines (no special plasma etching required).

- The “Ceramic” Advantage: The ceramic filler provides immense dimensional stability and high thermal conductivity ($0.6+ W/m/K$), making it excellent for Power Amplifiers (PA) where heat dissipation is critical.

Tier 4: PTFE / Teflon (The mmWave Specialist)

- Representative: Rogers RO3000 Series, Taconic TLY, Rogers RT/duroid

- Composition: PTFE (Polytetrafluoroethylene) with ceramic or glass fillers.

- Performance Profile:

- Dk: Can be as low as 2.2 (excellent for antennas).

- Df: As low as 0.0009 (Near zero loss).

- Analysis: When you enter the world of 77 GHz Automotive Radar or mmWave 5G, nothing else competes. PTFE has the lowest loss of any solid material.

- The Downside: It is soft (difficult to machine) and requires high processing temperatures. It is also dimensionally unstable, making it difficult to build multi-layer boards without specialized “bondply” layers.

IV. Head-to-Head Technical Comparison

Let’s compare these materials directly using data typically found in industry IPC-4103 slash sheets.

Comparison Table: Electrical & Thermal Properties

| Material Property | Standard FR-4 | Isola 370HR | Panasonic Megtron 6 | Rogers RO4350B | Rogers RO3003 (PTFE) |

| Material Base | Epoxy / Glass | High-Tg Epoxy | PPE Blend | Hydrocarbon Ceramic | PTFE / Ceramic |

| Dk (10 GHz) | ~4.5 (varies) | 4.04 | 3.70 | 3.48 | 3.00 |

| Df (10 GHz) | 0.0200 | 0.0160 | 0.0020 | 0.0037 | 0.0010 |

| Tg (°C) | 135 | 180 | 185 | >280 | N/A (Melts >327) |

| Thermal Cond. (W/m/K) | 0.25 | 0.40 | 0.42 | 0.62 | 0.50 |

| Moisture Absorption | >0.20% | 0.15% | 0.05% | 0.06% | <0.04% |

| Relative Cost | 1x | 1.5x | 3x – 4x | 4x – 5x | 8x – 10x |

The Battle: Megtron 6 vs. Rogers RO4350B

This is the most common question we receive from clients: “Should I use Megtron or Rogers?”

- Signal Integrity: Megtron 6 actually has a lower Df (0.002) than RO4350B (0.0037) at 10 GHz. For purely digital differential pairs, Megtron 6 is often superior.

- Impedance Control: Rogers RO4350B has tighter Dk control. If you are designing a band-pass filter where the Dk shifting by 1% ruins the filter response, Rogers is the winner.

- Thermal Management: RO4350B conducts heat significantly better. For high-power RF amplifiers, Rogers is the safer choice to prevent overheating.

- Manufacturing: Megtron 6 is a prepreg-based system ideal for lamination (multilayer boards). RO4350B is a core-based system; while you can make multilayer Rogers boards, they are often harder to laminate without using special bond plies (like RO4450).

V. Manufacturing Realities: Hybrid Stack-ups and Cost Control

Choosing the best material is easy if budget is unlimited. In the real world, cost optimization is key. This leads to the technique of Hybrid Stack-ups.

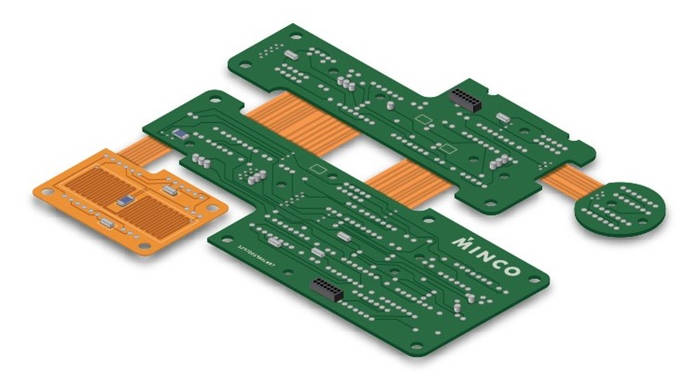

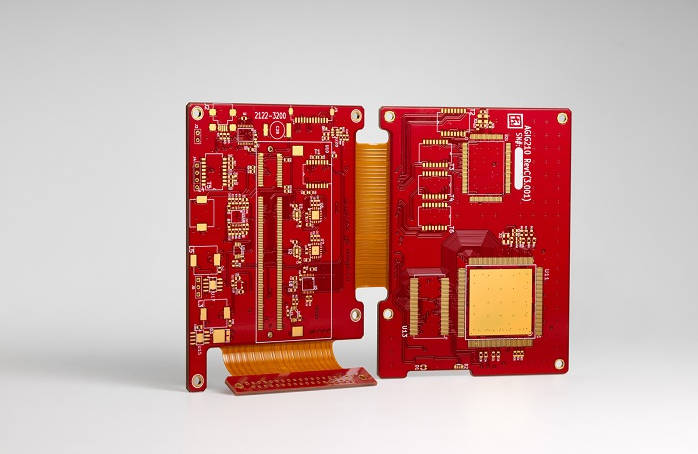

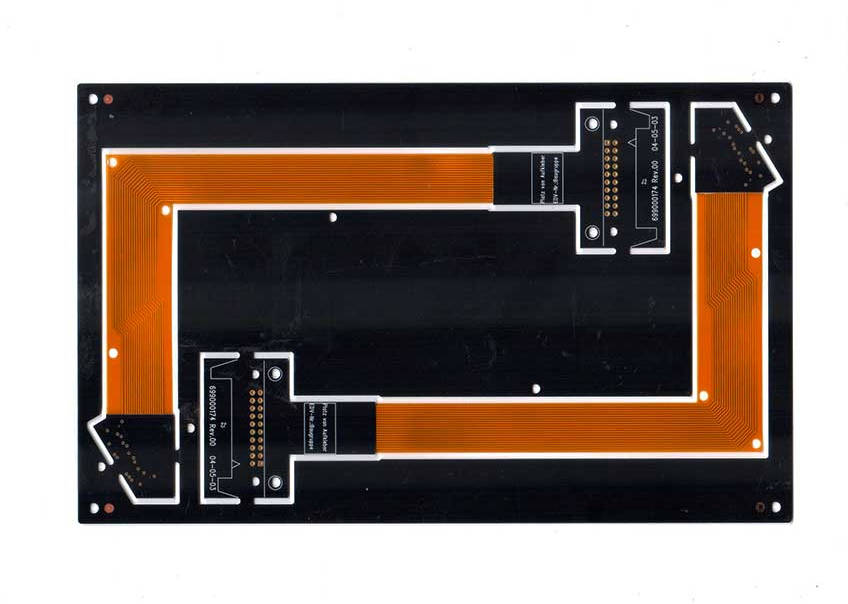

What is a Hybrid Stack-up?

A hybrid PCB mixes different materials in the same board.

- The Strategy: Use expensive high-speed material (e.g., Rogers RO4350B) only for the layers carrying critical high-frequency signals (usually the Top and Bottom layers).

- The Cost Saver: Use standard, cheaper FR-4 (or Isola 370HR) for the inner layers that only carry power, ground, or low-speed control signals.

The Challenges of Hybrid Fabrication

While cost-effective, hybrid boards are a nightmare for inexperienced PCB fab houses.

- CTE Mismatch: FR-4 and Rogers materials expand at different rates when heated. During the lamination process (pressing the layers together under heat), this mismatch can cause the board to warp or bow.

- Drilling Debris: Different materials produce different types of smear when drilled. The plasma cleaning cycle used to remove resin smear from FR-4 might not be aggressive enough for the Rogers material, or vice-versa.

- Prepreg Compatibility: You must ensure the “glue” (prepreg) used to bond the Rogers core to the FR-4 core is chemically compatible.

Pro Tip: Always define your stack-up before you start routing the layout. Send a preliminary request to your PCB manufacturer asking: “Can you manufacture a hybrid stack with RO4350B on L1/L2 and Isola 370HR for L3-L6?” Their engineering team will often adjust your design to match their verified hybrid process.

VI. Selection Guide: Matching Material to Application

Based on our analysis, here is the definitive selection guide for 2025.

Scenario A: The High-Speed Digital Board (Servers, AI Accelerators)

- Requirements: 25 Gbps+ data rates, long trace lengths, high layer counts (16-30 layers).

- The Problem: Signal attenuation over long traces (insertion loss) is the main killer.

- The Solution: Panasonic Megtron 6 (or Megtron 7).

- Reasoning: Its ultra-low loss (Df 0.002) combined with excellent processability for high-layer counts makes it the only logical choice. PTFE is too mechanically unstable for a 20-layer server board.

Scenario B: The RF Transceiver (WiFi 6E/7, Bluetooth, LoRa)

- Requirements: 2.4 GHz – 7 GHz, precise impedance matching for antennas, moderate heat.

- The Problem: Need stable Dk for filters and antennas; cost is a factor.

- The Solution: Rogers RO4350B.

- Reasoning: It offers the perfect balance. It’s significantly better than FR-4 for consistency but doesn’t have the high processing cost of PTFE. It is the “standard” for commercial RF.

Scenario C: Automotive Radar (77 GHz) & 5G mmWave

- Requirements: Extremely high frequencies (wavelengths in millimeters).

- The Problem: At 77 GHz, any dipole movement in the material absorbs the signal instantly.

- The Solution: Rogers RO3003 or Taconic TLY-5 (PTFE).

- Reasoning: You need a Df close to 0.001. No thermoset/epoxy material can achieve this. You must accept the higher cost and fabrication difficulty of PTFE to make the physics work.

VII. Conclusion: The Final Verdict

The question “Which dielectric wins?” has no single answer—it depends entirely on the frequency and application.

- For sheer speed in digital computing: Panasonic Megtron 6 wins. It is the backbone of the modern internet infrastructure.

- For general purpose RF and microwave: Rogers RO4350B wins. It provides ceramic stability with FR-4-like processing ease.

- For the millimeter-wave frontier (5G/Radar): PTFE (Rogers RO3003) wins. It is the only material capable of handling the extreme demands of 77 GHz+.

Advice for Buyers:

When requesting a quote, do not simply write “Rogers Material” on your fab notes. This is ambiguous and costly. Be specific.

- Instead of “Rogers,” specify “Rogers RO4350B, 20mil thickness, 1oz copper.”

- Consult your manufacturer about lead times. Rogers and Megtron materials can sometimes have lead times of 4-8 weeks if not in stock. Designing with a “standard stock” dielectric thickness can save months of project time.

By understanding the physics of Dk and Df, and balancing them against thermal reliability and cost, you can ensure your high-speed PCB performs flawlessly from the prototype stage to mass production.