Choosing the right Rogers PCB material is a critical decision that directly impacts the performance, reliability, and cost of your high-frequency electronic project. The selection process hinges on a careful analysis of your application’s specific electrical, thermal, and mechanical requirements. Key factors to consider include the operating frequency, the required dielectric constant (Dk), the acceptable signal loss (dissipation factor, Df), thermal conductivity for heat management, and the overall budget. By methodically matching these project needs to the distinct properties of different Rogers material families, you can ensure optimal signal integrity and long-term device stability.

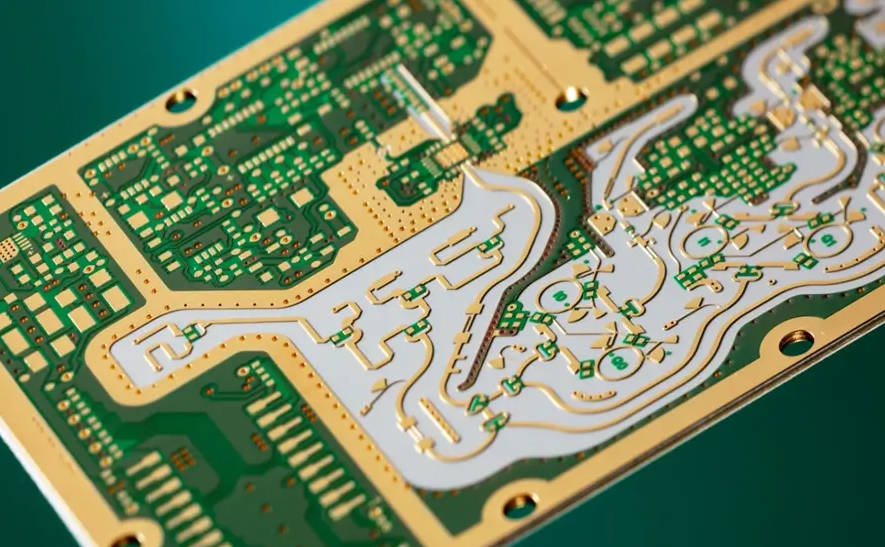

Unlike standard FR-4, which is a general-purpose, cost-effective laminate, Rogers materials are a family of high-performance substrates specifically engineered for demanding RF, microwave, and high-speed digital applications. Their superior electrical performance and stability come from their specialized composition, which often includes ceramic fillers in a PTFE (polytetrafluoroethylene) or hydrocarbon-based resin system. This guide will walk you through the essential criteria and provide a clear framework for selecting the perfect Rogers material for your next design.

Table of Contents

- The Core Four: Critical Electrical Properties to Consider

- Beyond the Basics: Essential Mechanical and Environmental Factors

- A Practical Guide to Rogers Material Families

- Matching Rogers Material to Your Application: A Quick-Reference Table

- Cost vs. Performance: Striking the Right Balance

- Your Quick Selection Checklist

- Conclusion: Making an Informed Decision

The Core Four: Critical Electrical Properties to Consider

The primary reason engineers choose Rogers over FR-4 is for superior and stable electrical performance at high frequencies. These four properties are the cornerstone of your material selection process.

What is the Role of Dielectric Constant (Dk)?

The dielectric constant, or relative permittivity, is arguably the most fundamental property of a PCB substrate. It determines the impedance of transmission lines and the speed at which signals propagate through the material. For high-frequency designs, what matters most is not just the Dk value itself, but its stability. Rogers materials excel here, offering a tight tolerance and remarkable consistency across a wide range of frequencies, temperatures, and humidity levels. A stable Dk ensures predictable impedance and timing, which is crucial for sensitive circuits like filters, couplers, and antennas. When choosing, consider not only the nominal Dk value needed for your impedance calculations but also the specified tolerance and its performance over your device’s expected operating frequency range.

Why is the Dissipation Factor (Df) or Loss Tangent So Important?

The dissipation factor (Df), also known as the loss tangent (tanδ), quantifies how much of a signal’s energy is absorbed and lost as heat within the substrate material. For high-frequency or high-data-rate signals, a low Df is paramount. A high Df leads to significant signal attenuation, degrading signal integrity, reducing the range of a wireless device, or increasing the bit error rate in a digital system. Rogers materials are engineered for extremely low Df values, often an order of magnitude lower than standard FR-4. When selecting a material, look at the Df specified at your target frequency. For applications above 10 GHz, such as millimeter-wave radar or 5G infrastructure, choosing a material from a series like RT/duroid® with an exceptionally low Df is non-negotiable.

How Does the Thermal Coefficient of Dk (TCDk) Affect Performance?

The Thermal Coefficient of Dielectric Constant (TCDk) measures how much the Dk value changes with temperature. In applications exposed to fluctuating thermal environments—like automotive radar, aerospace systems, or outdoor telecommunications equipment—a low TCDk is vital for stable performance. A high TCDk can cause filters to drift out of their passband, oscillators to change frequency, and phase-matched lines to lose their precise timing as the device heats up or cools down. Rogers RO3000® series, for example, is renowned for its industry-leading TCDk, making it a premier choice for temperature-sensitive applications where performance consistency is the top priority.

What is the Importance of Thermal Conductivity?

While an electrical property, thermal conductivity is about heat management. It measures a material’s ability to conduct heat away from active components like power amplifiers or high-speed processors. Inadequate heat dissipation leads to higher component temperatures, which can degrade performance, reduce reliability, and lead to premature failure. Rogers materials, particularly those with ceramic fillers, offer significantly better thermal conductivity than FR-4. This allows for more effective heat spreading across the PCB, reducing hot spots and potentially simplifying the overall thermal design of the system. For high-power RF applications or densely packed digital boards, selecting a material with higher thermal conductivity is a critical reliability consideration.

Beyond the Basics: Essential Mechanical and Environmental Factors

While electrical properties often take center stage, the mechanical and environmental stability of the substrate is just as crucial for the long-term reliability and manufacturability of your PCB.

Understanding the Coefficient of Thermal Expansion (CTE)

The Coefficient of Thermal Expansion describes how much a material expands or contracts with changes in temperature. This is incredibly important for PCB reliability, especially concerning plated through-holes (PTHs) and solder joints. The ideal scenario is to have the CTE of the substrate in the X and Y axes closely match that of copper. More importantly, the Z-axis CTE should be low to minimize stress on the PTH barrels during thermal cycling, which can otherwise lead to cracks and open circuits. Rogers materials are specifically engineered to have a low Z-axis CTE, drastically improving PTH reliability compared to FR-4, a critical advantage for devices that will experience significant temperature swings during their operational life.

How Does Moisture Absorption Impact Your PCB?

Moisture absorption can be detrimental to high-frequency PCB performance. When a substrate absorbs moisture from the environment, its electrical properties, particularly Dk and Df, can change significantly. This shift can detune sensitive circuits and increase signal loss, leading to inconsistent performance. Rogers materials, especially those based on PTFE, have extremely low moisture absorption rates. This inherent stability ensures that your device performs as designed, even in humid or uncontrolled environments, making them ideal for outdoor, marine, or aerospace applications.

Is Glass Transition Temperature (Tg) Still Relevant for Rogers Materials?

Glass Transition Temperature (Tg) is the temperature at which a PCB material transitions from a rigid, glassy state to a softer, more rubbery state. While it’s a primary specification for FR-4 (where a higher Tg indicates better performance during lead-free soldering), it is less of a defining characteristic for many high-performance Rogers materials, particularly PTFE-based ones. These materials do not have a distinct Tg in the same way FR-4 does and maintain their structural and electrical integrity at temperatures far exceeding standard assembly processes. However, for hydrocarbon-based series like RO4000®, the high Tg is still a testament to their excellent thermal and mechanical stability.

A Practical Guide to Rogers Material Families

Rogers organizes its materials into distinct families, each tailored for specific performance and processing needs. Understanding the key characteristics of the main series will help you narrow down your choices.

The Versatile Workhorse: RO4000® Series (Hydrocarbon Ceramic)

The RO4000® series, including popular materials like RO4350B™ and RO4003C™, is often considered the bridge between FR-4 and high-performance PTFE. These materials are glass-reinforced hydrocarbon/ceramic laminates, which means they offer excellent high-frequency performance while being processed using standard, low-cost FR-4 fabrication techniques. They provide a fantastic balance of performance, price, and ease of manufacturing.

- Best for: High-volume applications, automotive radar, power amplifiers, and high-speed digital designs where performance beyond FR-4 is needed without the cost and processing complexity of PTFE.

- Key Feature: FR-4 process compatibility.

The High-Performance Tier: RT/duroid® Series (PTFE Ceramic)

The RT/duroid® series, such as the industry-standard RT/duroid 5880, represents the pinnacle of low-loss RF performance. These materials are made from PTFE composites with ceramic fillers, resulting in extremely low dielectric loss (Df) and a very stable Dk. They are the go-to choice for the most demanding applications where preserving every fraction of a decibel of signal power is critical.

- Best for: Millimeter-wave applications, aerospace and defense systems, high-frequency satellite communications, and demanding test and measurement equipment.

- Key Feature: Extremely low signal loss.

The Temperature-Stable Choice: RO3000® Series (PTFE Ceramic)

The RO3000® series, featuring materials like RO3003™ and RO3010™, is distinguished by its exceptional Dk stability over temperature. They boast one of the best TCDk specifications on the market, ensuring consistent circuit performance across wide thermal ranges. This makes them ideal for environmentally sensitive applications.

- Best for: Automotive cruise control, GPS antennas, patch antennas for communications, and any RF circuit operating in an environment with significant temperature fluctuations.

- Key Feature: Best-in-class thermal stability of Dk.

Matching Rogers Material to Your Application: A Quick-Reference Table

To simplify your decision, here is a table that maps common applications to their key requirements and suggests suitable Rogers material series.

| Application | Key Requirements | Recommended Rogers Series |

|---|---|---|

| High-Speed Digital & Servers | Low Df, Controlled Dk, Good Thermal Conductivity, Cost-Effective | RO4000® Series (e.g., RO4350B) |

| Automotive Radar (77 GHz) | Low Df, Stable Dk over Temperature (Low TCDk), Low Cost for Volume | RO3000® Series, RO4000® Series |

| 5G/mmWave Telecom | Extremely Low Df, Very Stable Dk, Low PIM (Passive Intermodulation) | RT/duroid® Series, RO3000® Series |

| Aerospace & Satellite Comms | Extremely Low Df, Low Outgassing, Thermal Stability, Reliability | RT/duroid® Series (e.g., 5880) |

| RF Power Amplifiers | High Thermal Conductivity, Low Df, Stable Dk | RO4360G2™, RT/duroid® 6035HTC |

Cost vs. Performance: Striking the Right Balance

There is no denying that Rogers materials come at a premium compared to FR-4. The raw materials are more expensive, and some series may require specialized fabrication processes, which can add to the final cost. However, it’s crucial to view this not as an expense, but as an investment in performance and reliability. Over-specifying a material can unnecessarily inflate your bill of materials (BOM), while under-specifying can lead to product failure, costly redesigns, and a damaged reputation. The key is to select the material that meets, but does not excessively exceed, your design requirements. For many commercial applications, the RO4000® series offers an ideal compromise, delivering the necessary performance boost over FR-4 at a manageable price point. For mission-critical or extreme-performance designs, the higher cost of the RT/duroid® or RO3000® series is easily justified by the performance gains and assurance of reliability.

Your Quick Selection Checklist

Before finalizing your choice, run through this checklist to ensure you’ve covered all the bases:

- What is my maximum operating frequency? This will be the primary filter for eliminating unsuitable materials.

- How much signal loss (Df) can I tolerate? Be realistic. This will determine if you need a standard or an ultra-low-loss material.

- What is the required dielectric constant (Dk) for my impedance? Also, check the Dk tolerance.

- Will my device operate in a thermally fluctuating environment? If yes, prioritize a low TCDk.

- How much heat do my components generate? If significant, prioritize higher thermal conductivity.

- What is my budget and production volume? This will guide you between FR-4 process-compatible materials (RO4000®) and more specialized PTFE substrates.

- Have I consulted my PCB fabricator? Always confirm that your chosen fabricator has experience with and can process your selected material.

Conclusion: Making an Informed Decision

Choosing the right Rogers PCB material is a systematic process of aligning your project’s technical and commercial needs with the specific attributes of a substrate. By starting with a deep understanding of your operating frequency and signal integrity requirements, you can effectively use the core electrical properties—Dk, Df, TCDk, and thermal conductivity—to narrow your options. Factoring in mechanical reliability through CTE and environmental stability through moisture absorption further refines the selection. Finally, by understanding the trade-offs between different Rogers families and balancing performance against cost, you can confidently select a material that not only enables your design to function flawlessly but also ensures it remains reliable and manufacturable. This methodical approach transforms a complex decision into a clear path toward a successful high-performance product.

Rogers PCB material, how to choose Rogers PCB material, Rogers high frequency PCB material, Rogers PCB material selection guide, Rogers dielectric constant, dissipation factor, RO4350B, RT/duroid 5880, RO3003, high-speed pcb design, RF PCB material, microwave laminate