Low-Volume PCB Assembly Services

● Cost Efficiency

● Rapid Delivery

● Design Adaptability

● High Standards

Searching for Low-Volume PCB Assembly Services?

If you’re looking for low-volume PCB assembly services, Mars PCB is here to help. As a One-stop Printed Circuit Board PCB Assembly Manufacturer With 15+ Years Industry Experience, we offer production runs that start at around 25 boards and scale up to a few thousand. Our expertise and advanced equipment mean you can rely on us to deliver exceptional quality and support, no matter where you do business.

Definition of Low-Volume PCB Assembly

Low-volume PCB assembly refers to producing and assembling small orders, typically ranging from 25 to a few thousand pieces. This approach suits businesses developing new products, running pilot tests, or supplying niche markets with high-quality but smaller batches.

Advantages of Low-Volume PCB Assembly

Cost Efficiency

Undertaking large production of unproven designs can be risky. Early-stage feedback and potential recalls can become expensive if the designs aren’t fully validated. Low-volume PCB assembly minimizes such financial risks, helping you refine prototypes or small batches before rolling out extensive mass production.

Rapid Delivery

Low-volume assembly often requires less time on the production line, shortening overall lead times. You can anticipate receiving completed PCBs in just a few days—depending on the design complexity and quantity—so you can promptly test and finalize your products.

Design Adaptability

With short production runs, it’s easier to adjust design schematics or switch out components between iterations. This adaptability means you can rapidly incorporate feedback or experiment with emerging electronic parts without facing major production hurdles.

High Standards

Smaller batches allow our workforce to devote more attention to each individual board. This dedication promotes better assembly procedures and thorough checks, resulting in products that meet stringent international criteria.

Consistent Performance

When we commit more resources to short production runs, the possibility of errors goes down significantly. With less chance for oversights, the final boards become more reliable and stable in real-world applications.

How Much Does Low-Volume PCB Assembly Cost?

Manufacturing and assembling a small batch of PCBs typically costs between $0.02 and $0.05 per square inch—but this figure can vary based on multiple elements. Factors that can influence the final price per square inch include:

- Required labor for assembly

- Local labor costs

- Time spent on assembly processes

- Time spent on assembly processes

- Facility overheads

- Circuit complexity

Our Low-Volume PCB Assembly Core Capabilities

Mars PCB views PCB assembly as a holistic process that starts with the design phase. Here’s what we offer in our low-volume services:

A. Layout and Design

Our engineering team can assist in designing or refining your circuit boards if needed. Just give us your device’s functional requirements and the environment in which it operates. We will:

● Generate and optimize the PCB layout

● Provide prototypes for internal checks and further refinements

We have vast experience across communication devices, automotive electronics, industrial controllers, and more—enabling us to tackle various complexity levels and layer counts.

B. DFM (Design for Manufacturability) Evaluation

If you already have design files, we’ll review them for any potential production challenges. Our specialists use advanced design checks to help identify signal or component placement issues before fabrication starts, saving you time and money.

C. PCB Fabrication

Once we’ve validated the schematics and components, the fabrication process begins. Mars PCB’s factories in China are equipped to handle a broad range of materials—such as FR4, specialized metal-based substrates, and flexible laminates—and layer counts of up to 50 layers for complex designs.

D. Component Procurement

We have a streamlined global supply chain that grants us direct access to parts from reputable distributors, ensuring authenticity and competitive pricing. We also keep a well-stocked inventory of commonly used resistors, capacitors, chips, and more to speed up your assembly schedule.

E. Surface Coating Options

For environments prone to extreme moisture or temperature swings, we offer conformal coatings. These protective finishes (like epoxy, silicone, or urethane) keep your boards operating reliably in harsh situations, such as automotive engine bays or outdoor telecom enclosures.

F. IC Programming

We can handle firmware loading and device programming to make sure each assembled PCB is fully functional straight off the assembly line. Our technicians can use offline or in-circuit methods tailored to your particular requirements.

G. Stringent Testing

We implement a blend of in-circuit tests, functional tests, and specialized burn-in procedures to confirm each PCBA’s reliability. Additional tests are available based on the target application, including advanced imaging or contamination checks for higher-risk uses in medical, military, or telecom systems.

H. Prototype Builds

If you only need a handful of boards quickly, Mars PCB can fast-track prototyping. We combine CNC machining, precision etching, or other advanced techniques so you can verify and modify your product design in short, efficient cycles.

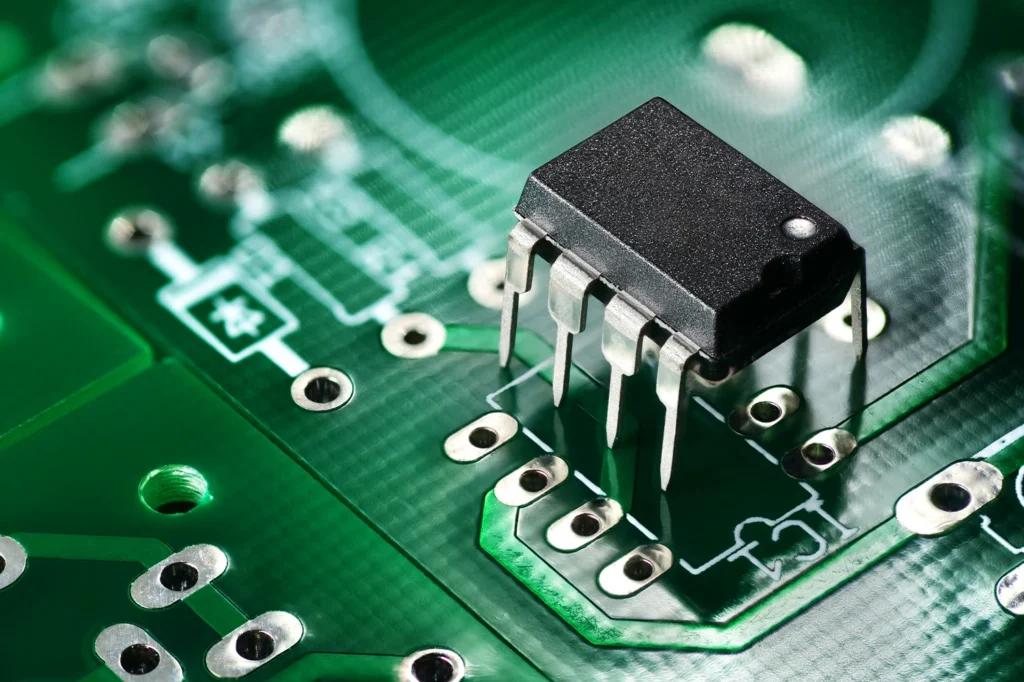

Assembly Techniques for Small Batches

● Surface Mount Technology (SMT): Places small components directly on the top of the board. Ideal for compact, performance-driven designs.

● Thru-Hole Technology (THT): Inserts leads through drilled holes in the PCB for robust mechanical support. Common in automotive and defense applications.

● Hybrid Approaches: Mixes surface-mounted parts with thru-hole solutions, offering the best blend of high-density packaging and secure mechanical fixes.

Quality Control in Low-Volume Production

At Mars PCB, each of our three facilities has a dedicated quality assurance unit staffed by trained inspectors who track your project from start to finish. We hold multiple certifications—ISO9001, ISO14001, IATF16949, OHSAS18001, ISO/IEC27001, ISO13485, and AS9100—ensuring that our boards comply with international benchmarks across different markets.

Why Pick Mars PCB for Low-Volume Assembly?

Since opening in 2002, Mars PCB has continuously focused on pushing innovation in PCB manufacturing. We now have three facilities in China, spanning more than 30,000 square meters and employing 500 skilled workers. Our collective monthly output can go up to 300,000 pieces. This extensive capacity allows us to dedicate specialized lines for low-volume assembly, guaranteeing efficient turnaround times.

Key reasons to work with Mars PCB include:

- Proven Experience: More than 15 years in business, delivering to thousands of clients worldwide.

- Cutting-Edge Equipment: We operate advanced lines for both assembly and testing, ensuring your boards meet or exceed expectations.

- Customized Approach: Every order is unique, and we tailor each production run to match your exact functional and aesthetic targets.

- Full Communication: We value transparency, keeping you informed at each milestone, including manufacturing progress and final QA results.

- Ongoing Support: You’re never left hanging. Our technical team remains ready to troubleshoot or provide additional help even after shipping.

Markets We Serve

Automotive engineering

High-frequency communication

Medical equipment manufacturing

Industrial automation

Defense and aerospace

Security systems

LED lighting and displays

Consumer electronics

How to Initiate Your Low-Volume PCB Project

1.Consultation: Provide us with your design schematics or a detailed concept.

2.Quotation: We deliver a comprehensive price estimate, including a timeline for prototype and final production runs.

3.Manufacture: Once confirmed, fabrication begins. Our team will keep you informed with frequent progress updates.

4.Delivery: After final testing, we’ll ship your boards via your preferred method. To begin, simply email us with your Gerber files, Bill of Materials, or overall design plan. You’ll then receive a detailed quote aligned with your technical specs.

Low-Volume PCB Assembly Services: Frequently Asked Questions

We can assemble parts of nearly any size, from small passives (like 0201) up to large connectors. We also deal with BGAs (ball grid arrays) and advanced chip packages.

We provide both leaded and lead-free solder. If you need products aligned with RoHS or environmental regulations, we’ll use lead-free materials. For specialized gear like automotive or defense projects, leaded solder might be a better choice.

Mars PCB: Your Comprehensive PCB Partner

Mars PCB is here to turn your concepts into finished products. Let’s bring your designs to life with expert SMT solutions.