When comparing PCB surface mount vs. embedded components for heat dissipation, embedded components generally offer superior thermal performance. This is because embedding a component within the PCB layers creates a 3D heat dissipation path, allowing heat to conduct away in all directions through the board substrate, significantly lowering thermal resistance. Surface mount components, while highly effective with techniques like thermal vias, are primarily limited to 2D heat spreading across the board’s surface and top casing, making embedded technology a more efficient solution for high-power density applications.

As electronic devices become smaller, faster, and more powerful, managing the heat they generate is one of the most critical challenges for PCB designers. The relentless push for miniaturization means more power is being packed into tighter spaces, turning thermal management from an afterthought into a primary design consideration. The choice of component mounting technology—the traditional Surface Mount Technology (SMT) or the advanced Embedded Component Technology (ECT)—plays a pivotal role in a product’s thermal performance, reliability, and overall lifespan. This article provides an in-depth comparison of these two technologies, exploring their thermal dissipation capabilities, design considerations, and ideal use cases to help you make the most informed decision for your next project.

Table of Contents

- Understanding the Basics: What Are Surface Mount and Embedded Components?

- The Physics of Heat Dissipation in PCBs

- Thermal Management Strategies for Surface Mount Components

- Unlocking Superior Cooling with Embedded Components

- Head-to-Head Comparison: SMT vs. ECT for Heat Dissipation

- Which Technology is Right for Your Application?

- Conclusion: Making the Right Thermal Design Choice

Understanding the Basics: What Are Surface Mount and Embedded Components?

Before diving into the thermal complexities, it’s essential to understand the fundamental differences between these two component placement philosophies. They represent distinct approaches to PCB assembly, each with its own set of advantages and challenges that directly influence heat management.

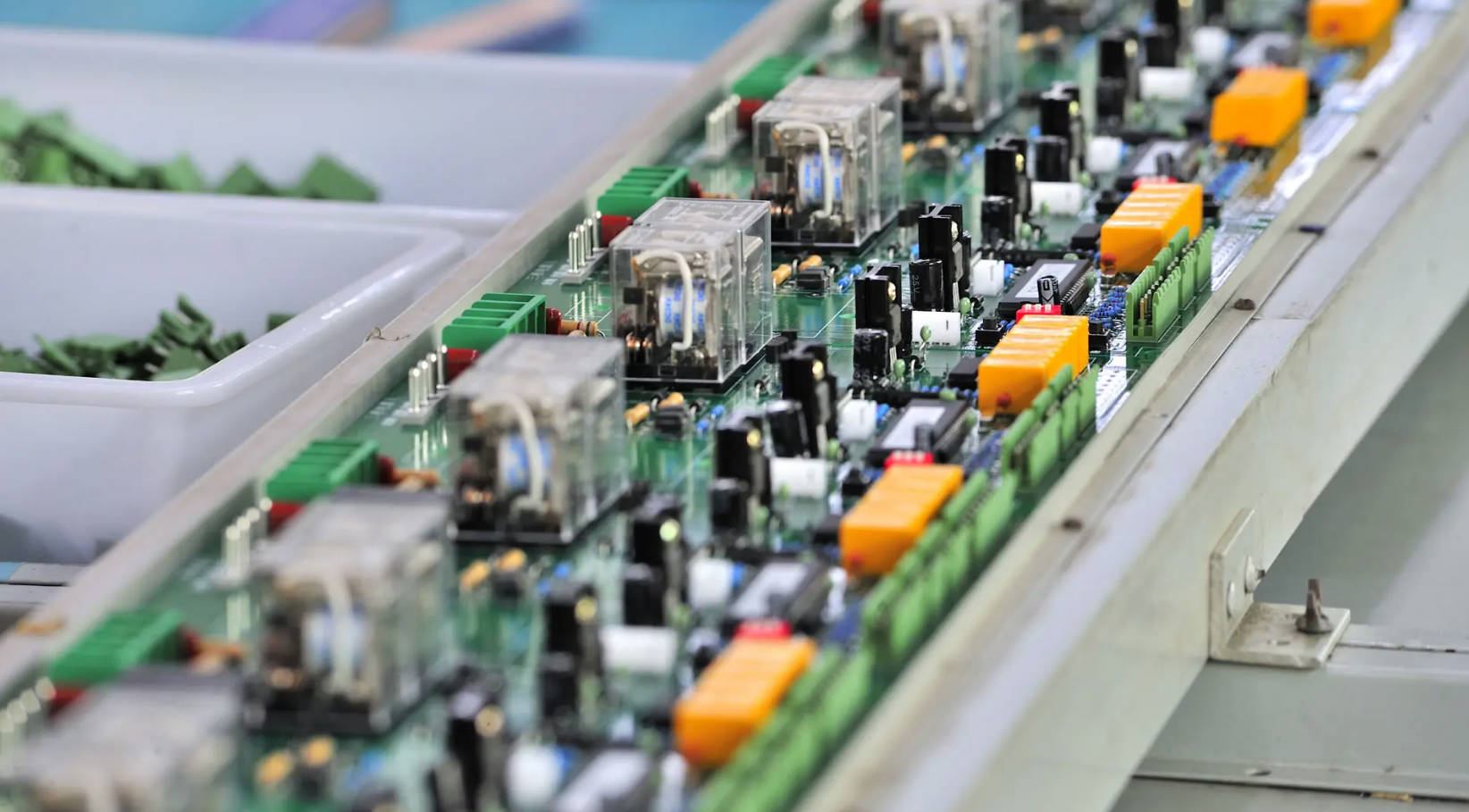

Surface Mount Technology (SMT): The Industry Standard

Surface Mount Technology is the most common method for placing components on a PCB. In this process, components, known as Surface Mount Devices (SMDs), are soldered directly onto pads on the surface of the circuit board. There are no leads that pass through the board, unlike the older through-hole technology. SMT revolutionized electronics manufacturing by enabling higher component density, smaller board sizes, and automated, high-volume production. Heat generated by an SMD must travel from the component’s silicon die, through its packaging, into the solder joints, and finally into the copper layers of the PCB, or dissipate from the component’s top surface into the surrounding air.

Embedded Component Technology (ECT): The Next Frontier in Miniaturization

Embedded Component Technology, also known as component embedding or buried components, involves placing active or passive components inside the layers of the PCB itself during the board’s fabrication process. The component is effectively sealed within the board’s substrate (e.g., FR-4). This radical approach offers significant benefits, including dramatic size reduction, improved signal integrity due to shorter connection paths, and enhanced EMI/RFI shielding. From a thermal perspective, ECT fundamentally changes the game by completely surrounding the heat-generating component with the PCB’s dielectric material and copper layers, creating a more holistic and efficient cooling environment.

The Physics of Heat Dissipation in PCBs

To effectively compare SMT and ECT, one must grasp the three primary mechanisms of heat transfer at play in a PCB: conduction, convection, and radiation. The efficiency of a thermal design hinges on optimizing these paths to move heat away from a sensitive component and into the ambient environment.

- Conduction: This is the transfer of heat through direct physical contact. In a PCB, it is the most critical mechanism. Heat conducts from the component’s die, through its package, into the solder, and then spreads through the copper traces, pours, and planes of the board. The thermal conductivity of the materials involved (copper, FR-4, solder) dictates the speed and efficiency of this process.

- Convection: This involves heat transfer through the movement of a fluid, which in this case is typically air. Heat that reaches the surface of the component or the PCB is transferred to the surrounding air. This process can be natural (relying on hot air rising) or forced (using a fan to increase airflow).

- Radiation: This is the transfer of heat through electromagnetic waves. Any object with a temperature above absolute zero radiates thermal energy. While less dominant than conduction and convection at typical operating temperatures, it still contributes to overall cooling, especially for components with large, dark surfaces.

A successful thermal management strategy aims to maximize conduction within the PCB to spread the heat and then maximize convection and radiation from the PCB and component surfaces to dissipate it.

Thermal Management Strategies for Surface Mount Components

SMT is a mature technology with a well-established portfolio of thermal management techniques. Designers have developed numerous methods to enhance the cooling of surface-mounted components, making it a highly viable option even for many power-intensive applications.

The Primary Heat Paths: Solder Joints and Component Casing

For a standard SMD, there are two main avenues for heat to escape. The first and most effective path is downward, through the component’s solder pads. Many power components, like QFN packages, feature a large, central exposed pad (thermal pad) designed specifically to be soldered to a large copper area on the PCB. This creates a low thermal resistance path for conduction directly into the board, which acts as a heatsink. The second path is upward and outward from the component’s plastic or ceramic casing. This heat is then removed primarily by convection (airflow) and radiation. The effectiveness of this path is heavily dependent on the ambient temperature, airflow, and the surface area of the component.

Enhancing SMT Cooling: The Role of Thermal Vias and Copper Pours

Designers are not limited to the basic heat paths. The most common technique to enhance SMT cooling is the use of thermal vias. These are small, plated holes drilled directly under the component’s thermal pad, connecting the top copper layer to internal and bottom copper planes. These vias act as thermal pipelines, dramatically reducing the thermal resistance and allowing heat to spread efficiently into a larger volume of copper and to the opposite side of the board. Combining thermal vias with large copper pours (solid areas of copper) on the surface and inner layers transforms the PCB itself into an effective, low-cost heat spreader, significantly boosting the conductive cooling potential.

Limitations and Challenges of SMT Thermal Management

Despite these enhancements, SMT has inherent thermal limitations. Heat dissipation is fundamentally a 2D-centric process. Heat spreads outward across the plane of the copper layer and downward through vias, but the component itself is thermally isolated on its sides. As component density increases, multiple heat-generating SMDs can create localized “hot spots” on the board, and their thermal zones can overlap, leading to a cumulative temperature rise. The reliance on surface airflow also means that performance can be compromised in sealed enclosures or densely packed systems where airflow is restricted. Ultimately, there is a physical limit to how much heat can be efficiently extracted from the top surface and a small footprint on the PCB.

Unlocking Superior Cooling with Embedded Components

Embedded Component Technology offers a paradigm shift in thermal management by integrating the component into the PCB structure. This opens up new and highly efficient pathways for heat dissipation that are simply not possible with surface mount devices.

The 3D Advantage: How Embedding Transforms Heat Flow

The single greatest thermal advantage of ECT is its ability to create a true 3D heat dissipation path. When a component is embedded, it is in direct contact with the PCB’s dielectric material and, more importantly, can be directly connected to multiple internal and external copper planes on its top, bottom, and even sides. Heat is no longer forced to flow primarily downwards; it can conduct outwards in all directions simultaneously. This 360-degree heat transfer drastically increases the effective surface area for conduction, allowing the entire board structure surrounding the component to act as an integrated, high-performance heatsink. This leads to a significantly lower junction-to-board thermal resistance compared to an equivalent SMT component.

Design Techniques for Maximizing Embedded Component Cooling

To fully leverage the 3D advantage, designers use specialized techniques. Stacked microvias can be placed directly on the component’s contact pads, creating a very short and direct thermal path to external layers. For high-power components, a cavity can be created in the PCB where the component is placed, and this cavity can then be filled with a thermally conductive paste or connected to a custom metal heat slug. This slug can extend to the outer surface of the PCB, providing an extremely low-resistance path for connection to an external heatsink or chassis. This approach effectively couples the embedded component’s heat directly to the outside world, bypassing much of the board’s internal thermal resistance.

Overcoming the Hurdles: CTE Mismatch and Manufacturing

The benefits of ECT come with significant challenges. A primary concern is the Coefficient of Thermal Expansion (CTE) mismatch. The embedded component (often silicon or ceramic) expands and contracts with temperature at a different rate than the surrounding organic PCB substrate (like FR-4). This can induce mechanical stress on the component and its solder joints during thermal cycling, potentially leading to long-term reliability issues. Careful material selection and advanced fabrication processes are required to mitigate this risk. Furthermore, the manufacturing process for PCBs with embedded components is far more complex and costly than standard SMT assembly. It requires specialized equipment and expertise, and any rework or repair of a faulty embedded component is practically impossible, which can have major implications for yield and cost.

Head-to-Head Comparison: SMT vs. ECT for Heat Dissipation

Choosing between SMT and ECT requires a careful evaluation of their trade-offs. While ECT often holds the thermal high ground, SMT’s cost-effectiveness and design simplicity make it the default choice for a reason. The following table provides a direct comparison of key attributes related to thermal performance and practicality.

| Attribute | Surface Mount Technology (SMT) | Embedded Component Technology (ECT) |

|---|---|---|

| Heat Dissipation Path | Primarily 2D (across board surface) and from the top of the component. | Truly 3D (omnidirectional into the board substrate). |

| Thermal Resistance (Junction-to-Board) | Higher. Relies on solder joints and thermal vias under the component. | Significantly Lower. Heat conducts in all directions into a larger volume. |

| Thermal Enhancement Techniques | Thermal vias, large copper pours, external heatsinks. | Stacked microvias, thermal slugs, conductive fillers, multi-layer connections. |

| Component Density & Hot Spots | Prone to localized hot spots and thermal crosstalk between adjacent components. | Better heat spreading reduces peak temperatures and mitigates hot spots. Allows for higher functional density. |

| Manufacturing Cost & Complexity | Low. Standard, mature, and highly automated process. | High. Requires specialized fabrication processes and tight quality control. |

| Rework & Repair | Relatively easy and standard practice. | Extremely difficult to impossible. A faulty component often means scrapping the entire board. |

| Reliability Concerns | Well-understood and generally high reliability. | Potential for CTE mismatch stress, delamination, and manufacturing defects. |

Which Technology is Right for Your Application?

The decision to use SMT or ECT is not a simple one. It is a strategic choice that depends on a delicate balance of thermal requirements, performance goals, size constraints, and budget.

When to Choose Surface Mount Technology

SMT remains the go-to choice for the vast majority of electronic designs, and for good reason. You should choose SMT when:

- Cost is a primary driver. SMT manufacturing is significantly cheaper and more widely available.

- Thermal requirements are moderate. For many applications, a well-designed SMT layout with proper copper pours and thermal vias is more than sufficient to manage heat.

- Time-to-market is critical. The design and manufacturing cycle for SMT is faster and more predictable.

- Reworkability and serviceability are required. The ability to easily replace a component is a massive advantage in prototyping, low-volume production, and long-life products.

- The design does not push the absolute limits of miniaturization. If you have adequate board space to implement proper thermal management features, SMT is the practical choice.

When to Opt for Embedded Component Technology

ECT is a specialized, high-performance solution for when standard methods fall short. You should consider ECT when:

- Extreme miniaturization is essential. For products like wearables, medical implants, or ultra-compact modules, embedding components is the only way to achieve the required form factor.

- Thermal performance is the top priority. In high-power density applications like advanced power converters, high-frequency RF modules, or compact motor drives, the superior cooling of ECT can be the enabling factor.

- Electrical performance is critical. The shorter interconnects offered by ECT can provide significant improvements in signal integrity and EMI, which may be as important as the thermal benefits.

- The budget and production volume can justify the higher cost and complexity. ECT is best suited for high-value products where its performance advantages outweigh its drawbacks.

- Rework is not a concern. For disposable modules or products with extremely high reliability requirements and validation, the impossibility of rework may be an acceptable trade-off.

Conclusion: Making the Right Thermal Design Choice

In the contest of PCB surface mount vs. embedded components for heat dissipation, embedded technology is the clear winner in terms of raw thermal performance. Its inherent 3D heat conduction path provides a lower thermal resistance and a more effective cooling solution than what is achievable with surface mount technology. By integrating the component into the board, the entire surrounding structure becomes part of the thermal solution, enabling unparalleled heat spreading in a minimal footprint.

However, this performance comes at a steep price in terms of cost, complexity, and a complete lack of reworkability. Surface Mount Technology, while thermally inferior on a purely theoretical level, is a remarkably capable and versatile workhorse. Through intelligent design using thermal vias, generous copper planes, and other established techniques, designers can successfully manage significant thermal loads in a cost-effective and manufacturable way. Therefore, the ultimate decision rests on the specific needs of the application. For the majority of projects, a well-executed SMT design will provide the optimal balance of performance, cost, and practicality. For those pushing the very boundaries of power density and miniaturization, Embedded Component Technology offers a powerful, albeit challenging, path forward.

PCB heat dissipation, surface mount components, embedded components, thermal management, surface mount vs embedded components heat dissipation, pcb thermal management techniques, embedded component thermal performance, smt component cooling, pcb thermal vias, pcb design for heat dissipation