Table of Contents

- 1. Introduction

- 2. What is FR4?

- 3. What is Polyimide?

- 4. Cost Comparison: FR4 vs Polyimide

- 5. Performance Differences

- 6. Application Differences

- 7. Choosing the Right Material

- 8. Conclusion

- 9. FAQ Section

1. Introduction

When you’re designing a printed circuit board (PCB), choosing the right material for the substrate is one of the most important decisions you’ll make. This choice dictates the board’s performance, durability, and ultimately, its cost. While there are many options available, FR4 and Polyimide are the two most commonly compared PCB materials because they represent a fundamental trade-off: affordability versus high-performance capabilities.

The main difference between Polyimide and FR4 PCBs lies in heat resistance, flexibility, and cost: FR4 is affordable and widely used, while Polyimide is ideal for high-temperature and flexible applications.

This article will dive into a detailed comparison of FR4 PCB and Polyimide PCB materials, exploring their costs, performance characteristics, and typical applications. We will also highlight why FR4 remains the industry standard for the vast majority of projects. Choosing the wrong material can lead to project failure or unnecessary expenses, so understanding these differences is crucial for any designer, engineer, or hobbyist. Whether you’re working on a simple consumer device or a mission-critical aerospace component, a solid grasp of these two materials is essential.

2. What is FR4?

FR4, which stands for Flame Retardant 4, is a grade designation for a glass-reinforced epoxy laminate. It’s a composite material made from woven fiberglass cloth with an epoxy resin binder that has become the global standard PCB substrate. This material has become the global standard for PCB substrates because it offers an excellent balance of properties at a low cost.

A key reason for its widespread adoption is its strong mechanical and electrical characteristics. FR4 is known for its rigidity and dimensional stability, which is essential for manufacturing both double sided FR4 PCB and complex multilayer FR4 PCB boards. Its dielectric constant (DK) is around 4.5, providing good insulation properties for a wide range of electronic applications. The standard glass transition temperature ($T_g$) for FR4 is approximately 130–140°C, though higher-grade versions are available for more demanding thermal environments.

Because of these features, FR4 PCBs dominate the consumer electronics, automotive, and industrial electronics markets. The material’s ease of manufacturing and global availability make it a perfect fit for high-volume production, from FR4 PCB prototype development to full-scale FR4 PCB manufacturing. Companies can find a reliable FR4 PCB supplier or China FR4 PCB manufacturer to produce a wide range of products, making the FR4 PCB cost and FR4 PCB price very competitive. This is why FR4 material PCB is the standard for over 80% of all PCB designs.

3. What is Polyimide?

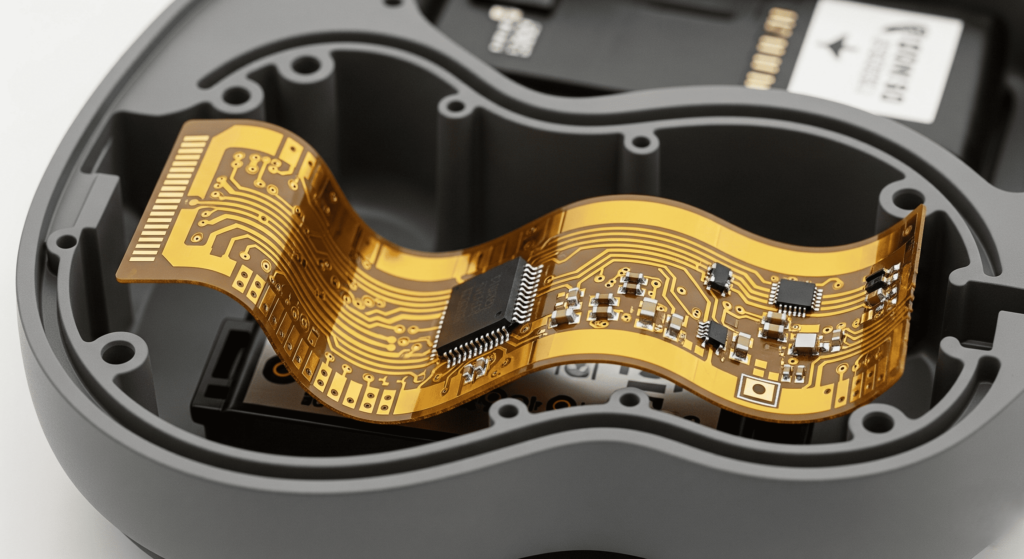

Polyimide is a high-performance polymer known for its flexibility, chemical resistance, and ability to withstand very high operating temperatures. Unlike the rigid nature of FR4, Polyimide is the foundation for flexible circuits and rigid-flex designs, which are essential for applications where space is limited or the circuit needs to conform to a specific shape.

The key properties of Polyimide highlight its high-performance nature. It boasts an exceptionally high glass transition temperature ($T_g$) of up to 260°C, making it suitable for extremely high-temperature environments where standard FR4 would fail. Its dielectric constant is lower than FR4, typically ranging from 3.5 to 4.0, which provides better electrical performance at high frequencies and is advantageous for signal integrity.

Due to its high cost and specialized properties, Polyimide PCBs are typically used in aerospace, military, and mission-critical applications where cost is secondary to performance. The unique combination of flexibility and thermal resistance makes Polyimide the only viable option for some mission-critical applications, such as those in oil and gas exploration or in devices exposed to extreme heat and chemicals.

4. Cost Comparison: FR4 vs Polyimide

When it comes to PCB materials, cost is often the deciding factor. This is where the difference between FR4 and Polyimide becomes most apparent. FR4 is an affordable and mass-produced material, making it ideal for cost-sensitive projects and high-volume manufacturing. The low FR4 PCB cost has made it the global standard for most consumer and industrial applications.

In contrast, Polyimide is a high-performance material with a much higher price tag. It is typically 2–4 times more expensive than FR4. This higher cost is due to the more complex manufacturing processes required for Polyimide, particularly in creating flexible and rigid-flex circuits.

Here is a comparison table that highlights the cost differences and their implications:

| Material | Relative Cost | Manufacturing Complexity | Typical Use Case |

|---|---|---|---|

| FR4 | Low | Standard, cost-efficient | Consumer and industrial electronics |

| Polyimide | High | Advanced, flexible PCB fabrication | Aerospace, defense, flexible circuits |

If cost is your priority, FR4 is the clear and practical choice. The higher cost of Polyimide is only justified when its unique performance benefits are absolutely necessary for the application.

5. Performance Differences

Beyond cost, the performance characteristics of FR4 and Polyimide set them apart. These differences are critical for designers who need to ensure their PCBs can withstand specific operational environments.

Thermal Properties

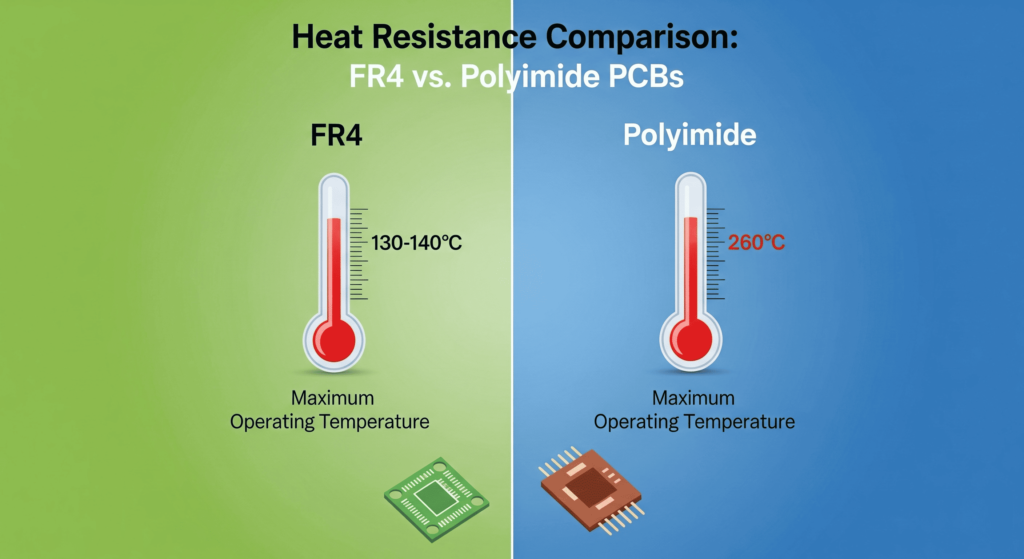

The most significant performance difference is in thermal stability. Standard FR4 has a glass transition temperature ($T_g$) of about 130–140°C, though high-temperature grades can go up to 170–180°C. This is sufficient for most commercial applications. Polyimide, however, can handle much higher temperatures, with a $T_g$) of up to 260°C. This makes it the superior choice for high-heat environments.

Mechanical Properties

FR4 is known for its rigidity, which provides mechanical strength and durability for rigid board designs. Polyimide’s key advantage is its flexibility and bend-resistance, making it perfect for applications that require a circuit to bend or fold, such as in FR4 flex PCB alternatives or rigid-flex designs.

Electrical Properties

Both materials are good insulators, but they have different dielectric properties. FR4 has a dielectric constant (Dk) of approximately 4.5, while Polyimide’s Dk is lower, typically between 3.5 and 4.0. This lower Dk means Polyimide has better electrical performance at high frequencies and provides superior signal integrity, which is crucial for high-speed digital and RF designs.

Here is a simple-to-read comparison table summarizing the key performance differences:

| Property | FR4 | Polyimide |

|---|---|---|

| Glass Transition Temperature ($T_g$) | ~130–140°C | ~260°C |

| Flexibility | Rigid | Flexible |

| Dielectric Constant (Dk) | ~4.5 | ~3.5–4.0 |

| Durability | High (for rigid use) | High (for flexible use) |

6. Application Differences

The stark differences in cost and performance between FR4 and Polyimide lead to distinct application areas for each material. The choice between them is dictated by the specific requirements and operating environment of the final product.

FR4 PCB Applications

FR4’s affordability and reliability make it the workhorse of the electronics industry. It is the preferred choice for a vast range of products where cost is a major consideration and operating conditions are not extreme.

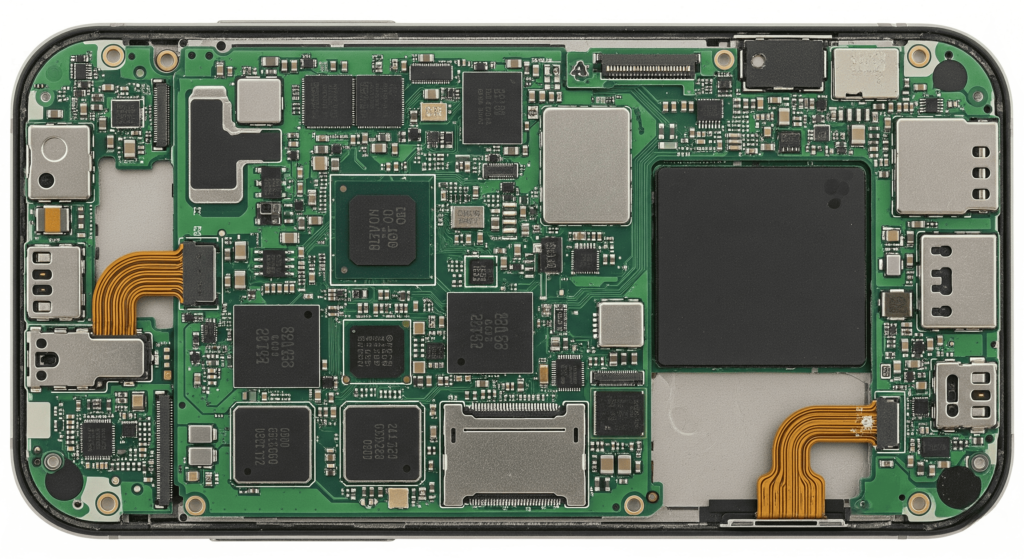

- Consumer Electronics: Devices like phones, laptops, and wearables almost universally use FR4 PCB boards due to the need for cost-effective, high-volume manufacturing.

- Automotive Control Units: Many non-critical automotive systems, from dashboard electronics to power supply circuits, rely on custom FR4 PCBs.

- Industrial Devices: Machines and power supplies in industrial settings benefit from the mechanical strength and stability of rigid FR4 material PCB.

- General Low-to-Mid Temperature Environments: For any device operating below 150°C, a standard FR4 board is a reliable and economical choice.

Polyimide PCB Applications

Polyimide is reserved for mission-critical and specialized applications where its unique properties are essential for the device’s function and reliability.

- Aerospace and Defense Equipment: In these fields, equipment must withstand extreme temperatures and environmental stress, making Polyimide’s thermal stability a non-negotiable requirement.

- Flexible Circuits (FPCs) and Rigid-Flex PCBs: Polyimide is the primary material for designs that need to bend or conform to tight spaces, such as in medical implants or advanced wearable technology.

- Harsh Environments: Industries like oil and gas exploration, where devices are exposed to high temperatures and corrosive chemicals, rely on Polyimide’s superior chemical resistance.

For the majority of commercial electronics, FR4 remains the most practical choice due to its optimal balance of cost and reliability.

7. Choosing the Right Material

Choosing between FR4 and Polyimide comes down to a simple, yet critical, set of questions about your project’s priorities.

Choose FR4 if:

- Your design is cost-sensitive and intended for mass production. The low FR4 PCB fabrication and assembly costs make it ideal for competitive markets.

- You are manufacturing consumer or industrial products. For most of these applications, the standard performance of FR4 is more than adequate.

- The operating temperatures are below 150°C. FR4 performs reliably within these temperature ranges.

- You need a rigid board with excellent dimensional stability.

Choose Polyimide if:

- Your PCB must survive extreme environments, such as high heat or chemical exposure.

- You need a flexible PCB design to fit into a non-standard form factor.

- Reliability is more important than cost. Polyimide’s durability and superior performance in demanding conditions justify its higher price.

Ultimately, in over 80% of PCB designs, FR4 is the go-to material because it offers the best trade-off between cost, performance, and manufacturability. It provides a reliable and affordable foundation for most electronic devices, making it the industry standard.

8. Conclusion

Both Polyimide and FR4 have unique strengths that make them valuable in different contexts. Polyimide excels in extreme and flexible applications, but FR4 dominates the global PCB market because it is reliable, cost-effective, and versatile. For most PCB buyers and designers, FR4 PCBs are the optimal solution unless your project specifically requires the extreme heat resistance or flexibility of Polyimide. This fundamental difference in priority—affordability and versatility versus high-performance—defines their respective roles in the world of electronics manufacturing.

9. FAQ Section

- Is FR4 cheaper than Polyimide? Yes. FR4 is significantly cheaper, often 2–4x less costly than Polyimide.

- Can FR4 PCBs withstand high temperatures? Standard FR4 can handle up to ~130–140°C, but high-Tg FR4 options can go higher (~170–180°C).

- When should I use Polyimide instead of FR4? Use Polyimide for aerospace, defense, or flexible PCBs where high thermal or chemical resistance is required.