China Rigid-Flex PCB Manufacturer

2 - 30 Layers

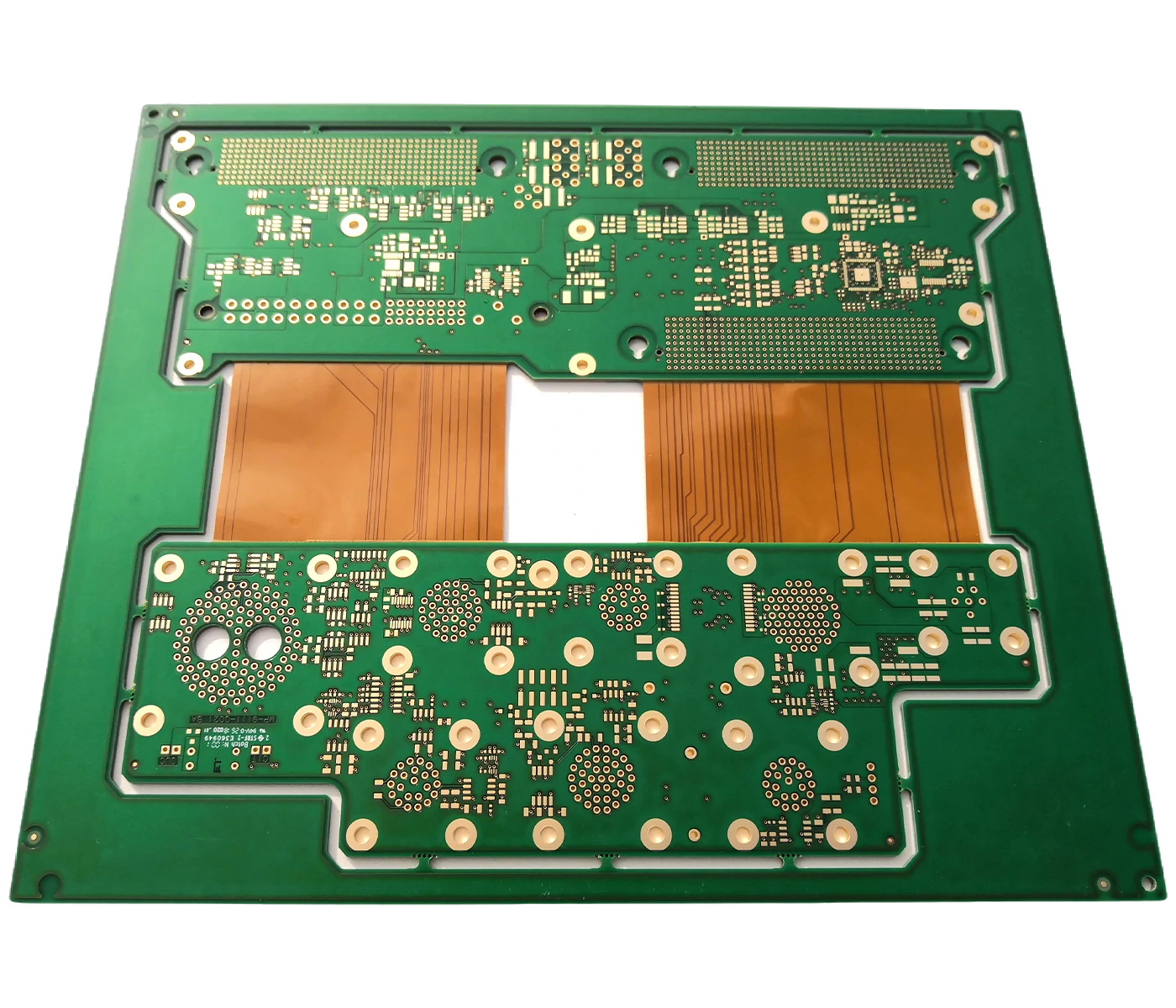

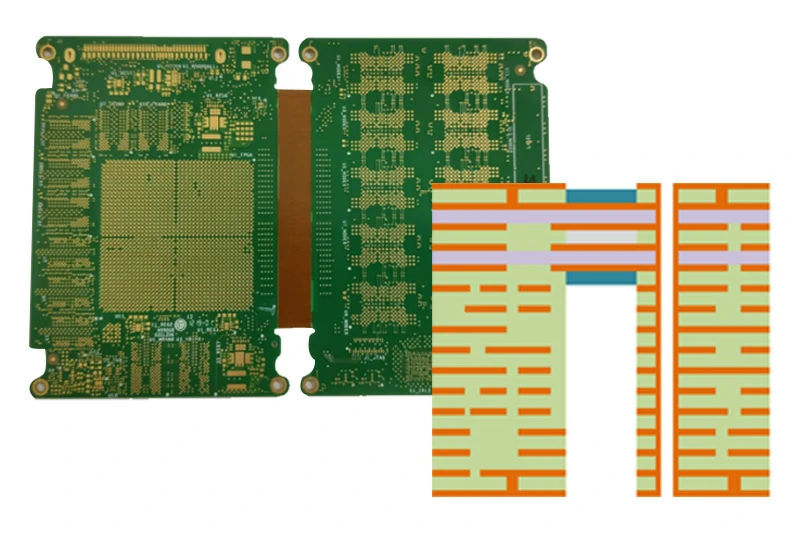

Rigid-flex PCBs have become an integral part of modern electronics, combining the durability and stability of rigid PCBs with the flexibility of flexible circuits. This hybrid PCB technology allows for more compact, reliable, and efficient designs. Mars PCB manufacturing service specializes in producing high-quality rigid-flex PCBs, offering the best in both performance and reliability for various industries.

What is a Rigid-Flex PCB?

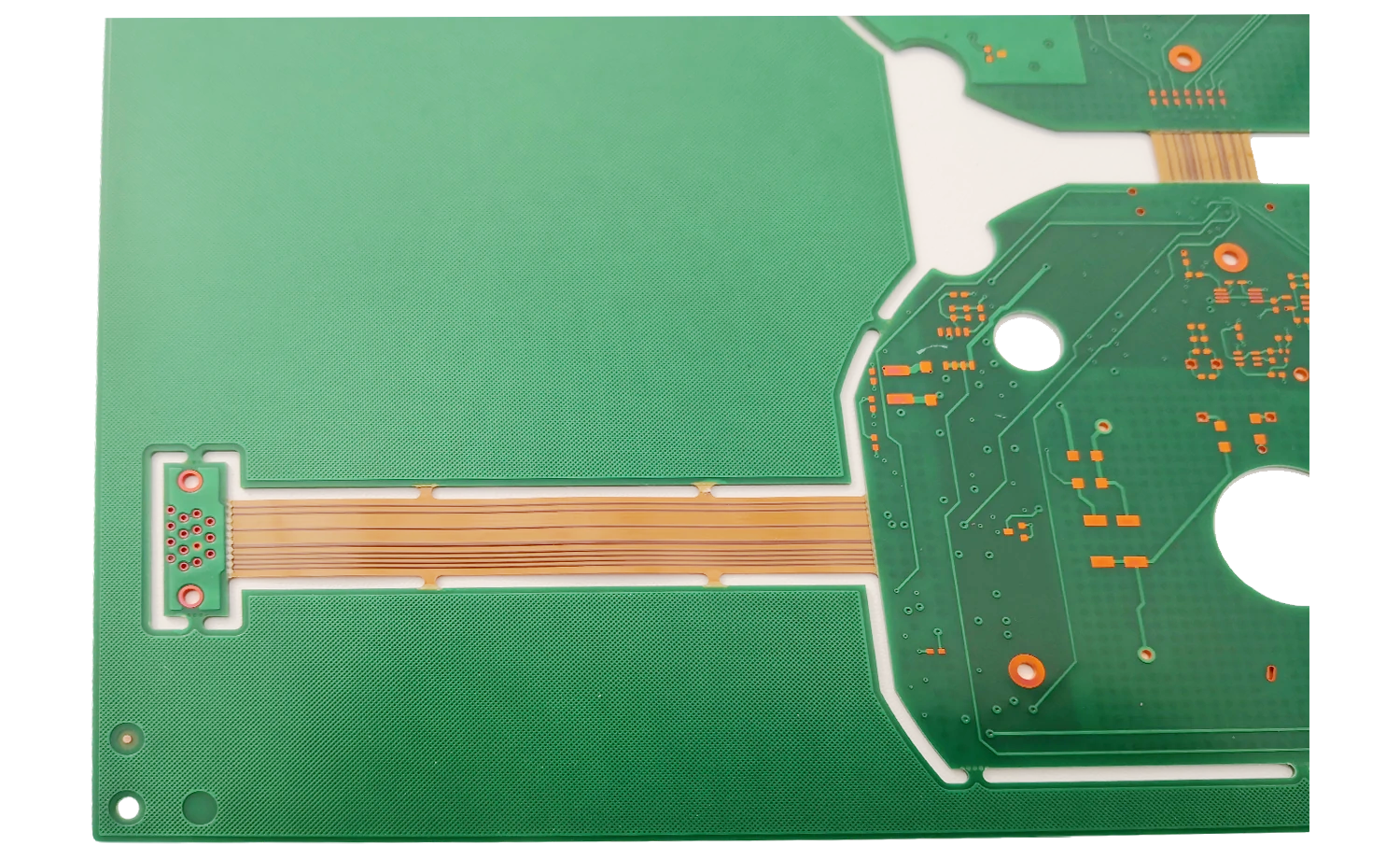

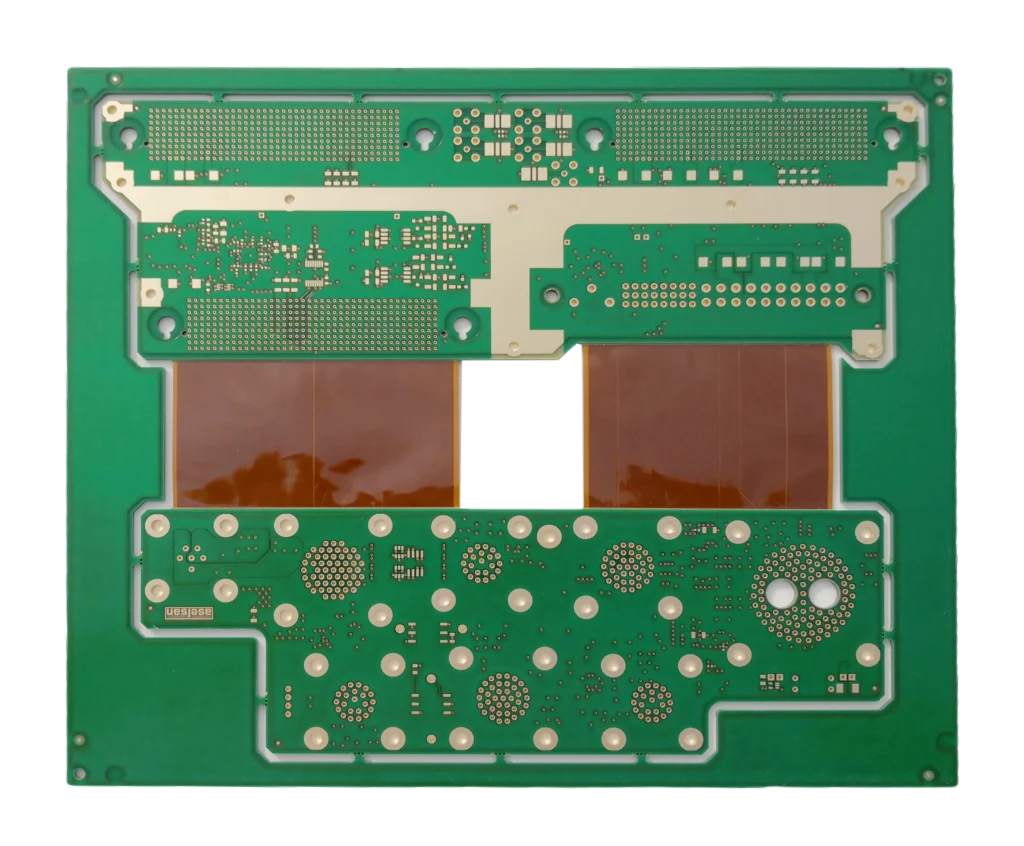

Rigid-flex PCBs are a combination of flexible polyimide (PI) or polyester (PET) layers with rigid FR4 layers. The flexible layers typically range from 1 to 6 layers, while the rigid sections can be 1 to 24 layers, depending on the design requirements. These boards are interconnected with advanced techniques like through-holes and microvias, enabling high-density, fine trace designs.

In our manufacturing process, the flexible PCB is fabricated first, and then rigid FR4 layers are laminated on top. We use lasers to trim the rigid areas, exposing the flexible sections for bending. This allows for lightweight, compact designs without sacrificing performance.

Mars PCB produces rigid-flex PCBs in a range of applications, including automotive, medical, aerospace, and telecommunications, with configurations available from 2 to 30 layers. We also offer flexible PCBs with stiffeners if you don’t need full rigid-flex designs.

Advantages of Rigid-Flex PCBs

By integrating both rigid and flexible circuits into a single unit, designers can eliminate the need for bulky connectors, wires, and cables. This reduction in components results in a smaller, lighter product. Industries such as aerospace and medical technology benefit from these compact designs, where space and weight constraints are crucial.

The hybrid nature of rigid-flex PCBs provides both dynamic stability and the ability to flex without compromising structural integrity. This makes them ideal for high-vibration applications, such as automotive and industrial equipment, where traditional rigid PCBs would fail due to constant movement.

Rigid-flex PCBs offer significant design freedom. The ability to incorporate flexible areas into rigid sections allows designers to create devices that fit more complex and irregular spaces, facilitating highly compact and efficient designs. This is especially beneficial for industries focused on miniaturization, such as consumer electronics and medical devices.

Fewer interconnections and components simplify the repair process. With reduced connectors and cables, the likelihood of failure points is minimized, which can lead to lower maintenance costs. This feature is particularly valuable in mission-critical systems, where reliability is paramount.

Rigid-flex PCBs are designed to withstand extreme environmental conditions such as high temperatures, humidity, and exposure to chemicals. This makes them suitable for aerospace, military, and industrial applications, where electronic components must function reliably under severe conditions.

We label halogen-free PCBs as per customer requirements. If no specific instructions are given, we mark the outer box The design of rigid-flex PCBs reduces the number of solder joints and connectors, enhancing th overall reliability of the circuit. This is vital in sectors like military and medical, where failure can have severe consequences. Rigid-flex PCBs ensure long-lasting performance even under demanding conditionse.with "HF."

While the upfront cost of rigid-flex PCBs may be higher compared to traditional PCBs, they often lead to significant cost savings in the long run. The reduction in connectors, cables, and assembly labor leads to lower production costs. Additionally, the improved reliability of rigid-flex PCBs reduces the need for replacements and repairs.

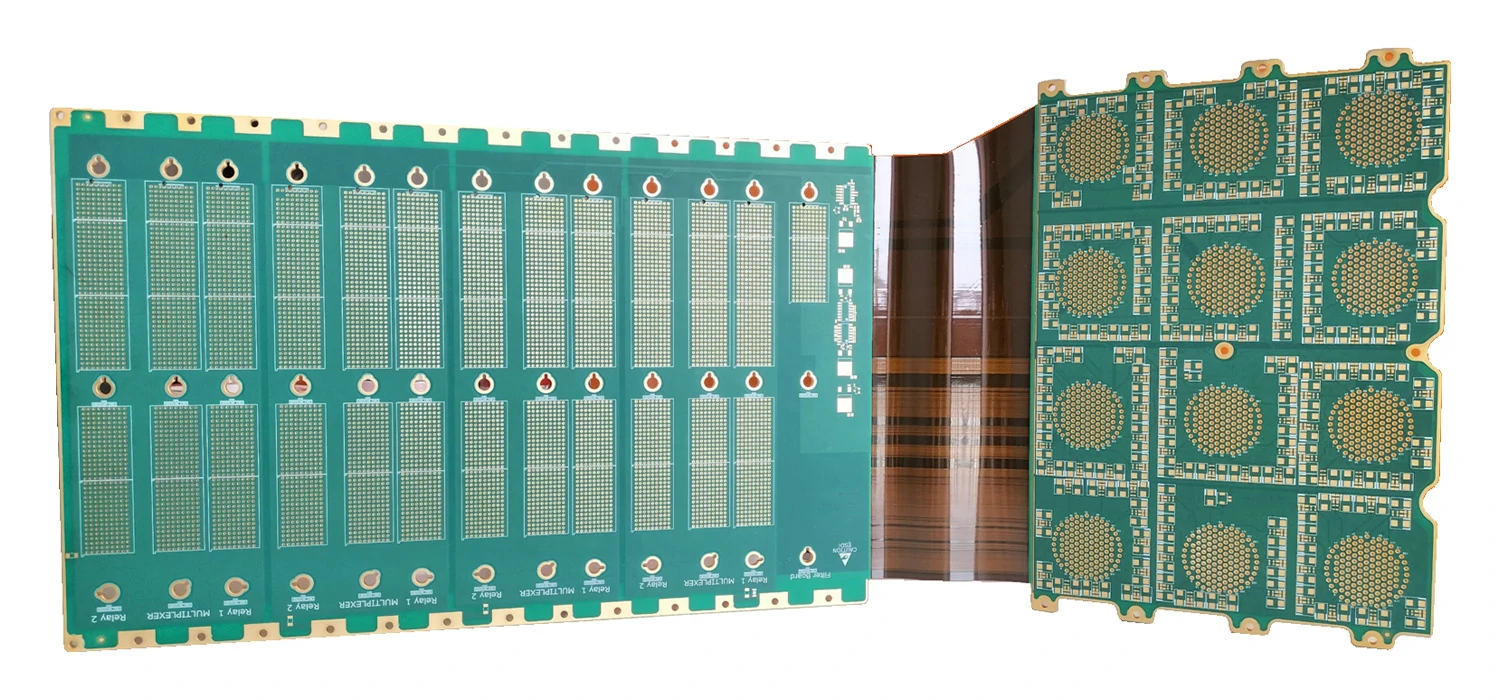

Featured Cases Study

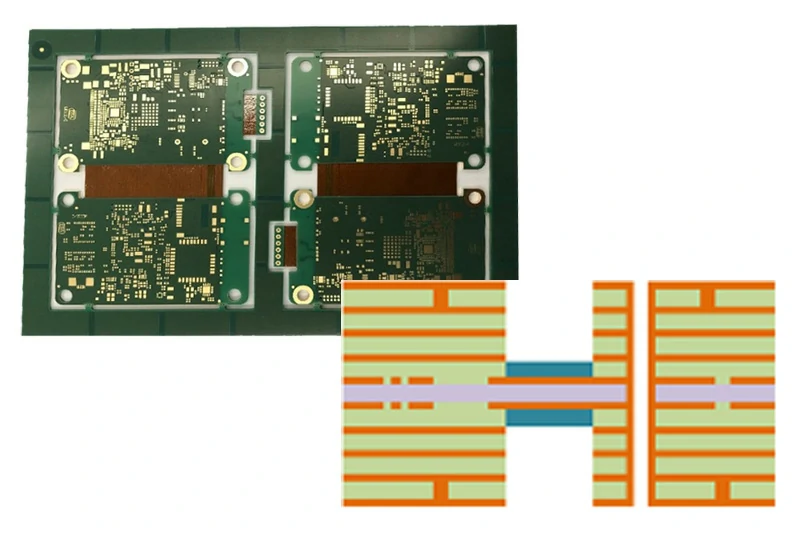

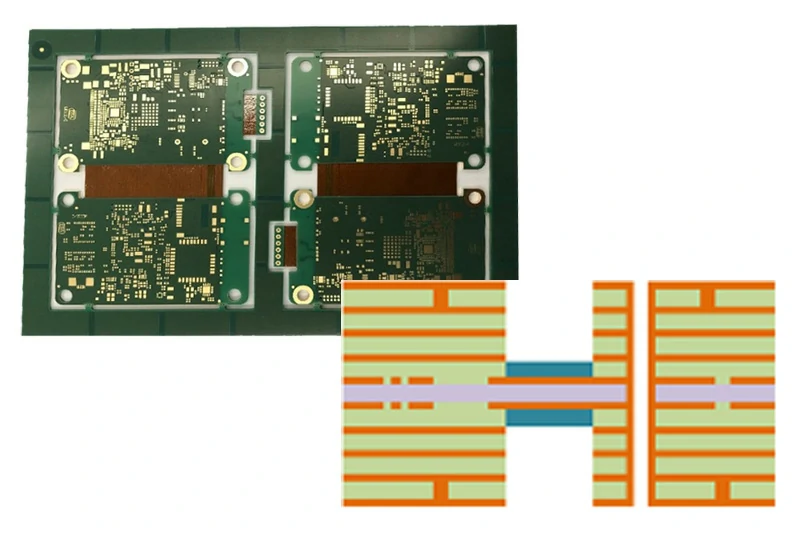

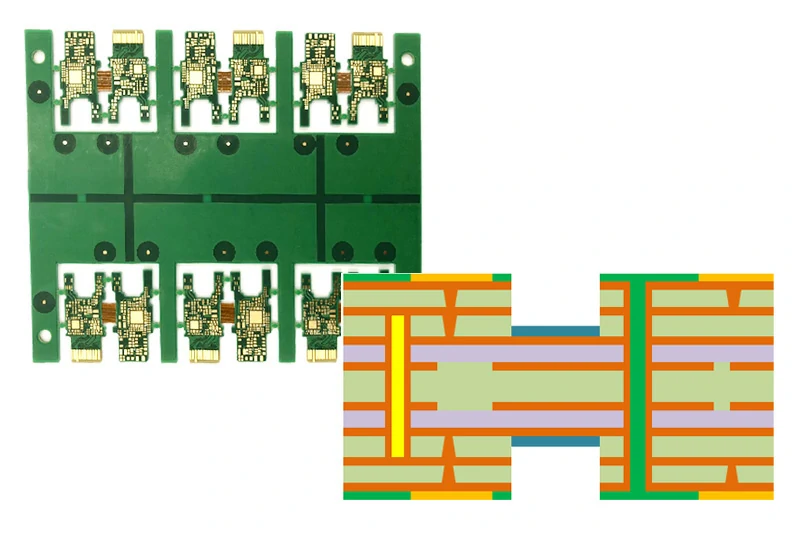

16L HDI /4L Flex/ 1.6mm

TU862HF+AP8535R

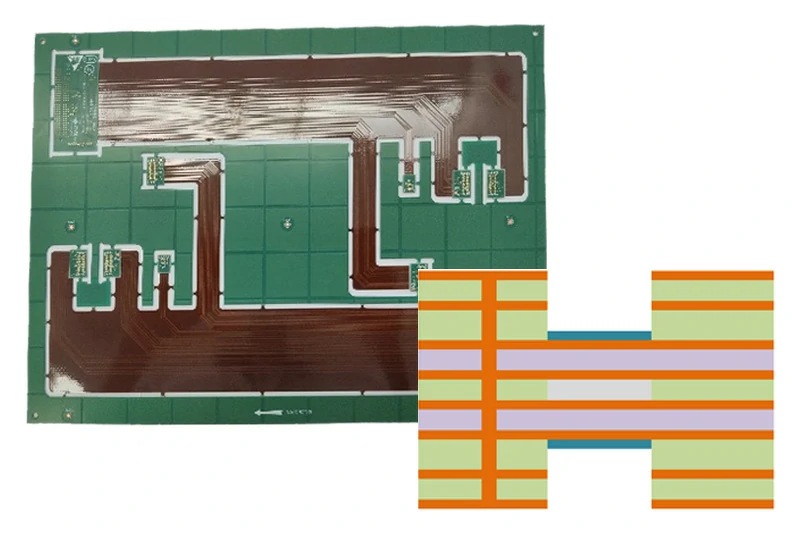

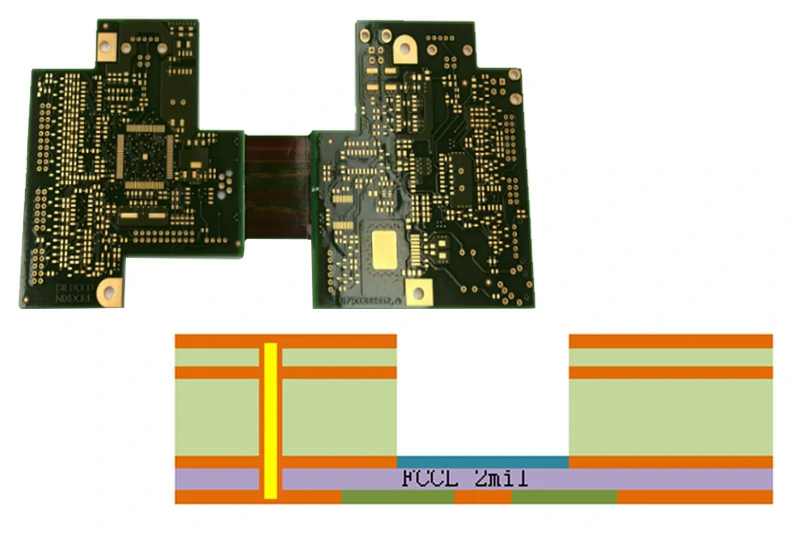

10L HDI/ENIG/1.45mm

Autolad1+SF202

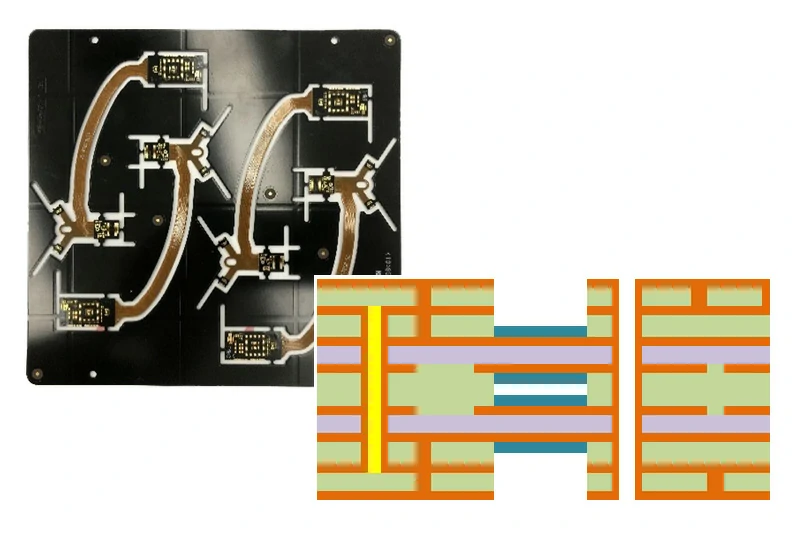

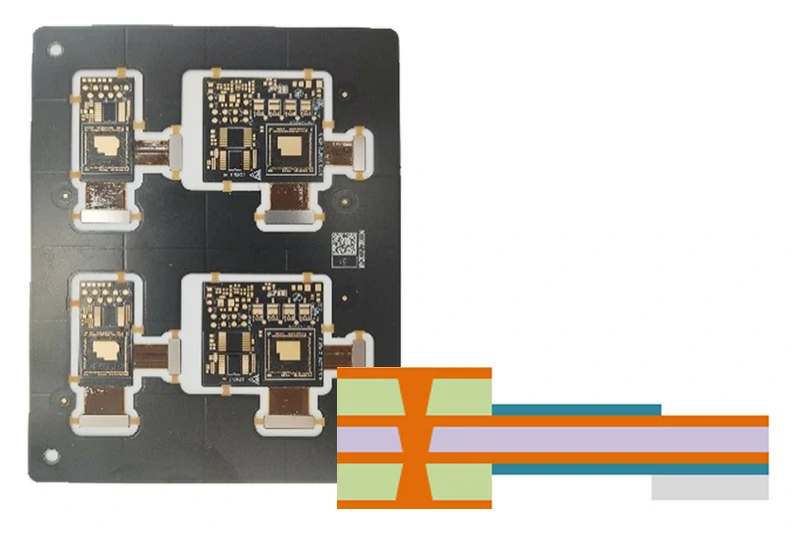

8L Total /4L Flex/2.0mm

S1000-2M+R-F775

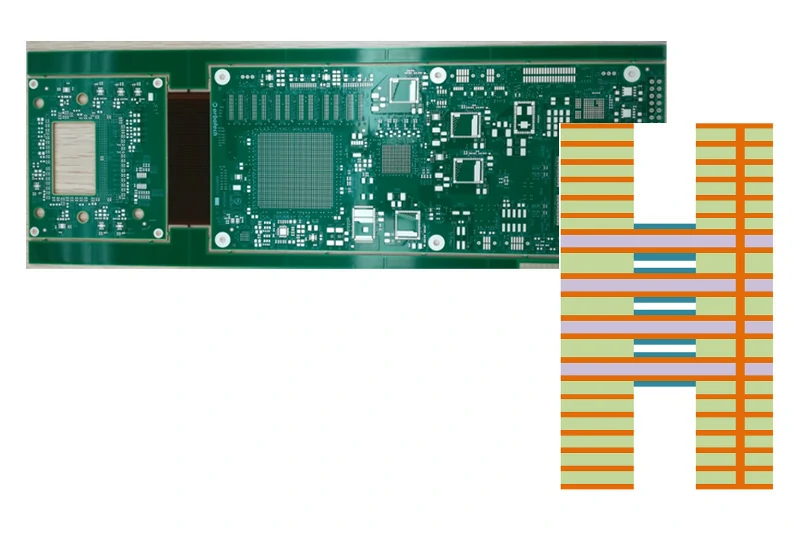

8L HDI/air-gap/ mm

S1000H+AP8535R

8L HDI/1.05mm

S1000H+SF202

8L HDI/1.0mm

IT180A+AP8535R

4L/2F-2R/Flex SM/1.575mm

S1000H+SF202

4L anylayer/WB Pad/0.4mm

S1000-2M+SF202

20L Total/8L Flex/air-gap/2.5mm

S7439+R-F775

Applications of Rigid-Flex PCBs

Rigid-flex PCBs are widely used across various sectors due to their versatile nature and ability to handle both rigid and flexible demands. Some of the common applications include

Rigid-flex PCBs are used in compact, reliable medical equipment like pacemakers, diagnostic tools, and imaging systems, where size and performance are crucial. Their ability to withstand high stress and temperature fluctuations ensures the longevity of life-saving devices.

In the defense sector, rigid-flex PCBs are integral to communication systems, navigation equipment, and weapon systems, where durability and reliability are critical. These PCBs can endure extreme conditions such as temperature changes, shock, and vibration.

Rigid-flex PCBs are used in satellites, avionics, and unmanned aerial vehicles (UAVs). Their ability to function reliably in space environments, which subject them to severe vibration and temperature extremes, makes them an essential component of aerospace technology.

Automotive systems like infotainment, sensors, and engine control units benefit from rigid-flex PCBs' ability to withstand constant vibrations and fluctuating temperatures. This reliability in automotive electronics ensures long-lasting, high-performance systems.

In consumer devices such as smartphones, laptops, and wearable technology, rigid-flex PCBs contribute to thinner, more reliable, and compact designs. Their flexibility allows manufacturers to push the boundaries of miniaturization and device performance.

Rigid-flex PCBs are used in industrial settings where electronic components are exposed to high temperatures, vibrations, and chemicals. Their robustness ensures they remain functional in even the harshest environments.

Design Considerations for Rigid-Flex PCBs

When designing a rigid-flex PCB, there are several key factors to consider

The flexibility of the PCB should match the application’s bending needs. Designers must consider the bending radius, the number of flex cycles, and the expected environmental conditions to ensure optimal performance.

Materials such as polyimide for flexible layers and FR-4 for rigid layers are commonly used. The choice of adhesive materials is equally important as it impacts both the flexibility and thermal performance of the PCB.

Proper heat dissipation is crucial for the longevity and performance of rigid-flex PCBs. Strategies like thermal vias, heatsinks, and component placement are used to manage heat effectively.

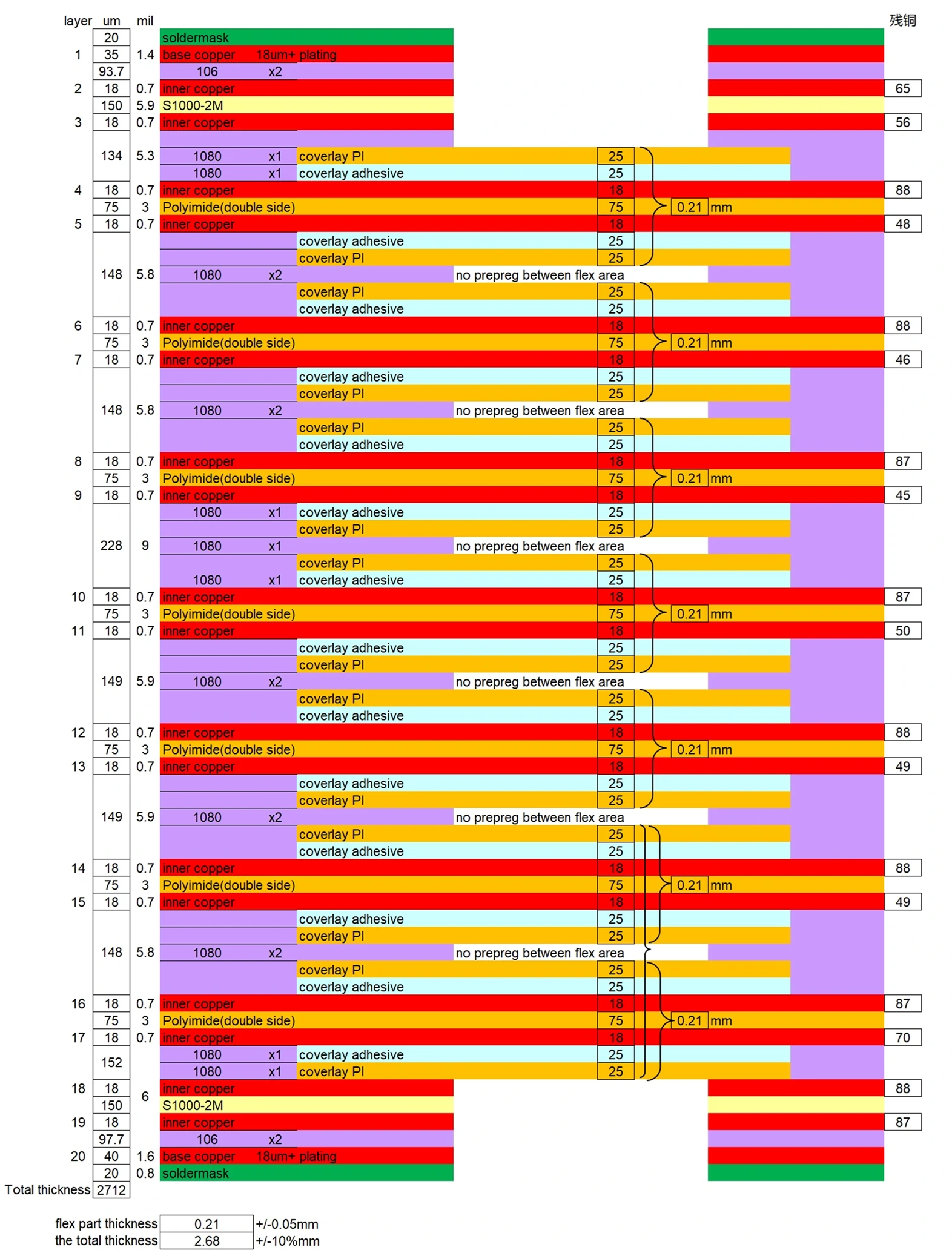

The arrangement of rigid and flexible layers affects the electrical performance and mechanical stability of the PCB. Proper stackup ensures signal integrity and heat management, which is essential for maintaining the PCB's performance over time.

Manufacturing Process of Rigid-Flex PCBs

The manufacturing process of rigid-flex PCBs involves several steps to ensure quality and precision

This includes cleaning substrates to remove any contaminants that may affect bonding during the lamination process.

Photolithography is used to create circuit patterns on the PCB substrate.

Unwanted copper is removed to leave behind the desired circuit design.

Precision drilling creates the necessary holes for component placement and electrical interconnections between layers.

Flexible and rigid layers are bonded together under heat and pressure to form the rigid-flex structure.

The final PCB is cut to size and shaped according to the design specifications.

Layers of conductive material are applied to improve electrical conductivity and durability.

Rigid-Flex PCB Manufacturing Capabilities

Specification | Mars PCB Rigid-Flex PCB Capabilities |

Flex PCB Layer Count | 1 to 6 |

Rigid-Flex PCB Layer Count | 2 to 30 |

Production Time | 1 day to 4 weeks |

Board Size | Min. 4mm x 4mm to Max. 457mm x 610mm |

Final Thickness | 0.05mm to 0.6mm |

Materials | Polyimide or polyester, FR4, RA copper, HTE copper, adhesive |

Thickness in Flex Section | 0.01mm to 0.1mm |

Min. Assembly Pitch | 0.35mm |

HDI Stack-up | 1+N+1, 2+N+2, 3+N+3, 4+N+4 |

Aspect Ratio | 3:1 |

Copper Thickness | 1/3oz to 3oz |

Min. Trace Width/Space | 1.6mil/1.6mil |

Min. Drill Diameter | 6mil |

PTH Tolerance | ±2mil |

Surface Finishes | ENIG, OSP, HASL, Immersion Tin, Silver, Gold, Hard Gold |

Advantages of Mars PCB’s Rigid-Flex Manufacturing

Mars PCB offers high-quality materials for multilayer PCBs, including FR4, rigid-flex, flexible, aluminum, copper, and ceramic. For FR4 boards, we use high-Tg material to ensure durability and performance.

Mars PCB has specialized production lines, including advanced immersion gold technology, providing industry-leading capabilities in multilayer PCB manufacturing.

Our experienced engineers can optimize your multilayer PCB design and provide personalized support to meet your specific needs, ensuring a smooth production process from start to finish.

Mars PCB follows a rigorous ISO-based quality management system. Our multilayer PCBs are certified to ISO 9001, IATF 16949, RoHS, REACH, UL, and IPC standards, guaranteeing the highest quality and reliability.

Mars PCB provides end-to-end services, from PCB design and prototyping to assembly, testing, and delivery. We offer flexible, customized solutions based on your project requirements.

Mars PCB offers a range of shipping options, including air, sea, and rail services through trusted carriers like DHL, FedEx, and UPS. We also allow you to choose your preferred freight forwarder.

Cost Considerations for Rigid-Flex PCBs

The cost of rigid-flex PCBs depends on factors like the number of layers, Raw material, thickness, circuit complexity, surface finishes, and production lead time. While prototyping costs are generally higher, the unit price for large-volume production is more economical.

Rigid-flex PCBs are more complex to manufacture than traditional FR4 or flexible PCBs, and therefore, they come at a higher cost. Typically, rigid-flex boards can be 2 to 3 times the price of flexible PCBs and 8 to 10 times more expensive than FR4 boards.

For example, 4-layer rigid-flex PCBs with a total area of 0.1 square meters might cost around $900, while the same configuration in FR4 would cost about $100. Mars PCB offers competitive pricing, ensuring the best value for your investment.

Mars PCB works directly with clients to offer cost-effective solutions and high-quality PCBs. By working directly with us, you can save significantly compared to third-party agents or brokers.

PCB Type | Low Complexity | Medium Complexity | High Complexity |

Rigid PCB | $1 – $10 | $10 – $50 | $50 – $200+ |

Flex PCB (Single-Sided) | $5 – $20 | $20 – $75 | $75 – $300+ |

Flex PCB (Double-Sided) | $10 – $30 | $30 – $100 | $100 – $500+ |

Rigid-Flex PCB (4-Layer) | $20 – $50 | $50 – $200 | $200 – $1,000+ |

Rigid-Flex PCB (6-Layer) | $50 – $100 | $100 – $500 | $500 – $2,000+ |

Why Choose Mars PCB for Your Rigid-Flex Needs?

- Premium Quality: We provide top-notch rigid-flex PCBs that meet industry standards and ensure reliable performance.

- Custom Solutions: Our services are tailored to your specific requirements, ensuring that your PCB meets all design and application needs.

- Expert Guidance: Our experienced team supports you throughout the design and manufacturing process to guarantee the best results.

- Cost-Effective Manufacturing: We optimize production processes to offer competitive pricing for both small and large runs without compromising quality.

Professional PCB & PCB Assembly Manufacturer & Factory

From concept to completion, your project will be under experienced project management, sparing you the hassle of untimely conference calls, communication gaps, language barriers and “real time” information gathering.