SMT Assembly

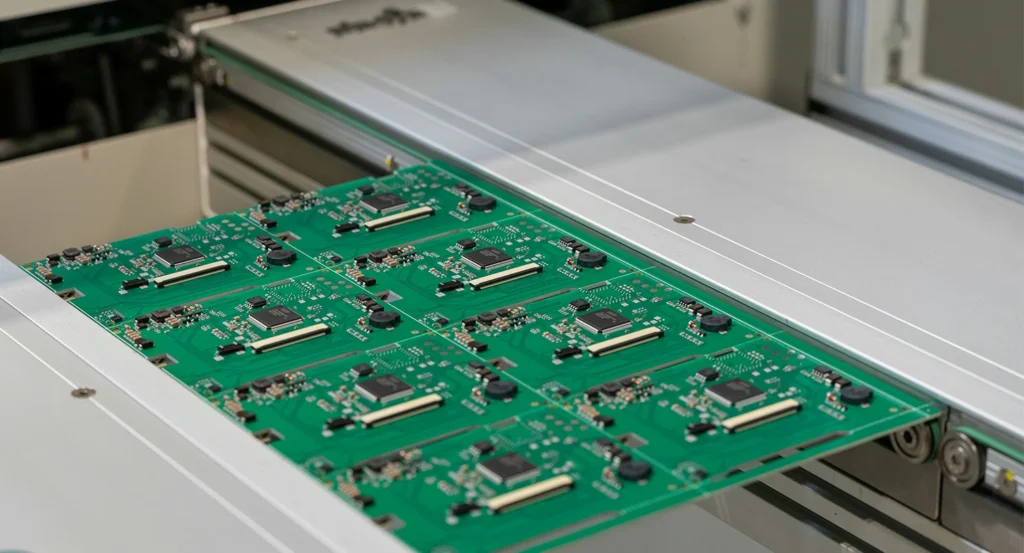

Mars PCB specializes in comprehensive PCB assembly solutions, incorporating modern Surface Mount Technology (SMT) methods. SMT involves attaching electronic parts straight onto the board surface, which helps shrink the product’s overall footprint and reduce weight. By merging extensive assembly experience with SMT’s strengths, Mars PCB creates durable, top-grade assemblies that meet diverse application needs.

Surface Mount Technology (SMT)Assembly

Mars PCB delivers professional PCB assembly services using advanced SMT. By placing compact electronic parts on the board surface, SMT cuts down both size and weight. By fusing technical mastery with high-quality assembly practices, we ensure each product addresses precise electronic requirements.

PCB assembly usually features two major mounting approaches: Surface Mount Technology (SMT) and Through-Hole Technology (THT). Many modern projects rely on SMT for miniaturization. Sometimes, both are used together if a design requires both small form factors and sturdier component leads.

What Is Surface Mount Technology?

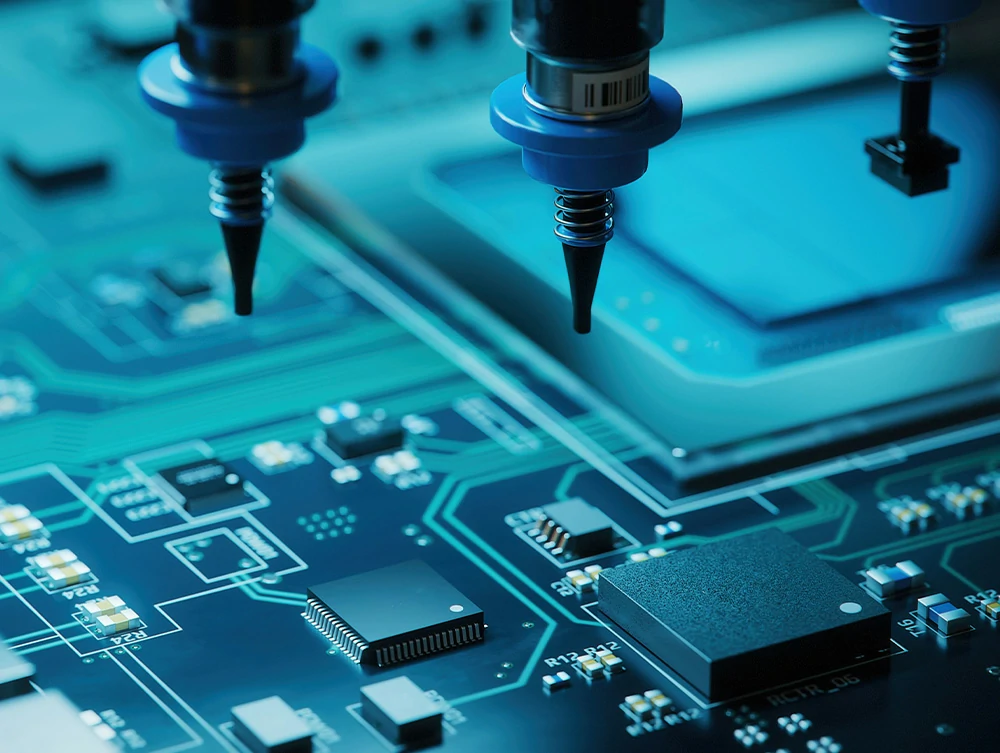

Surface Mount Technology (SMT) is a way of assembling PCBs by soldering components straight onto the board. This technique uses printers for solder paste application, pick-and-place machines for automated component placement, and reflow ovens to secure parts firmly to contact pads.

Different Types of SMT

SMT typically comes in three forms:

SMT Type | Description |

Type I | Uses only surface-mount devices on one or both sides of the PCB. |

Type II | A blend of THT and SMT elements, where main components and DIP parts sit on top, and smaller SMT parts often go underneath. |

Type III | Similar to Type II, but the top side mainly has DIP parts, while passive SMDs appear on the bottom. |

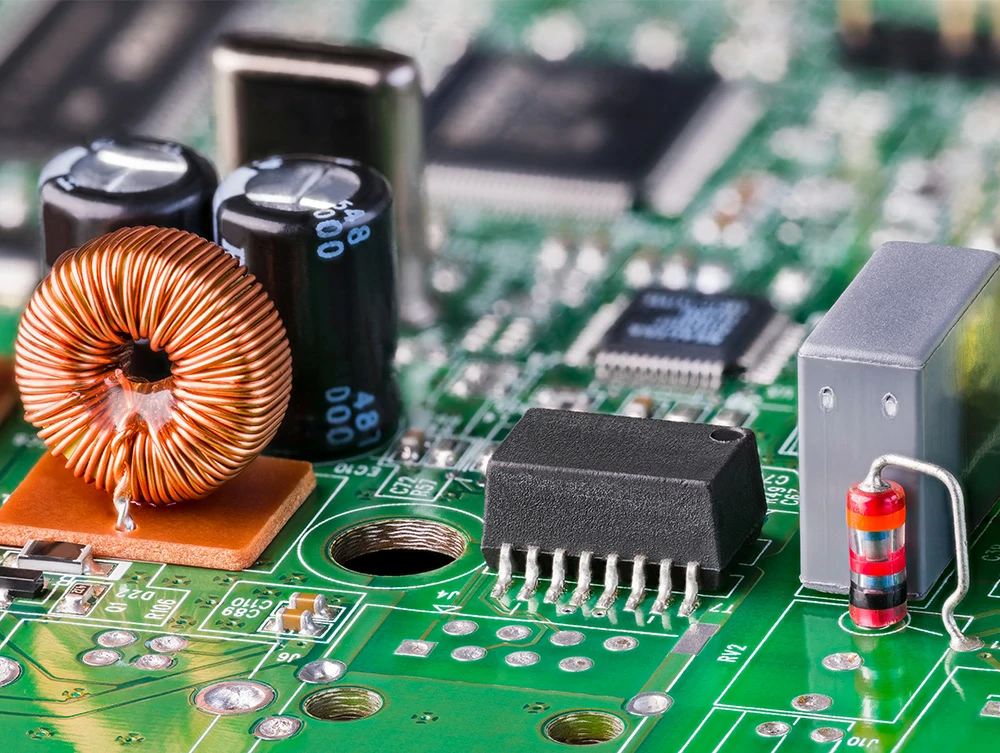

Common Components in SMT

Resistors control current flow, while capacitors store and release electrical charges. Both come in smaller SMT sizes and are vital in various circuits.

ICs contain multiple tiny parts like transistors, diodes, and resistors on a single chip, ranging from simple logic units to complex microprocessors.

Diodes permit current to flow in one direction, and transistors amplify or switch signals. Both are vital for power regulation and signal handling.

Inductors store energy in a magnetic field, while transformers pass energy between circuit parts using magnetic induction.

SMT connectors link external devices to the board. Switches control circuit on/off states and can be embedded on the board surface.

The SMT Manufacturing Process

A solder paste printer spreads solder paste through a metal stencil directly over the correct pads.

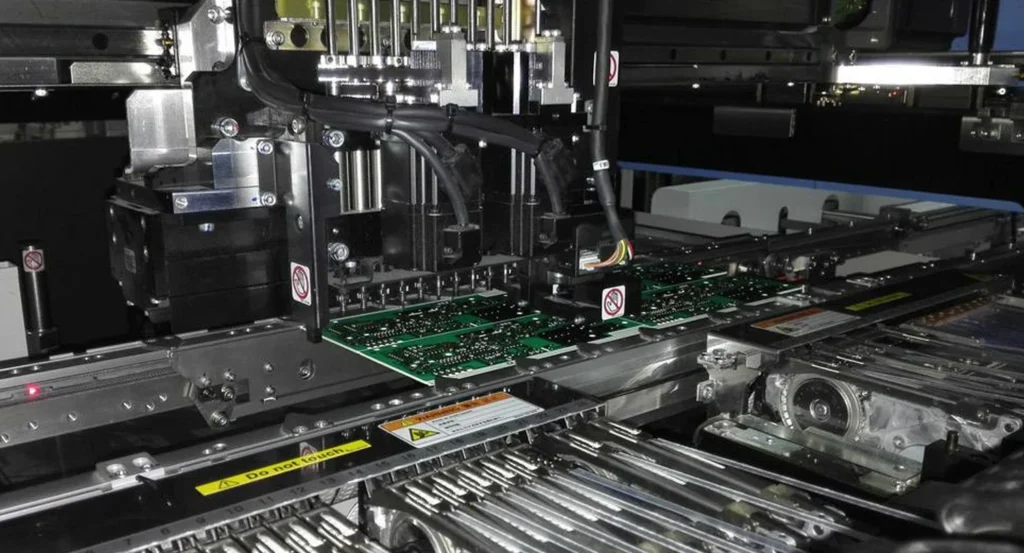

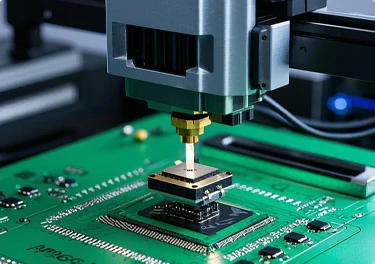

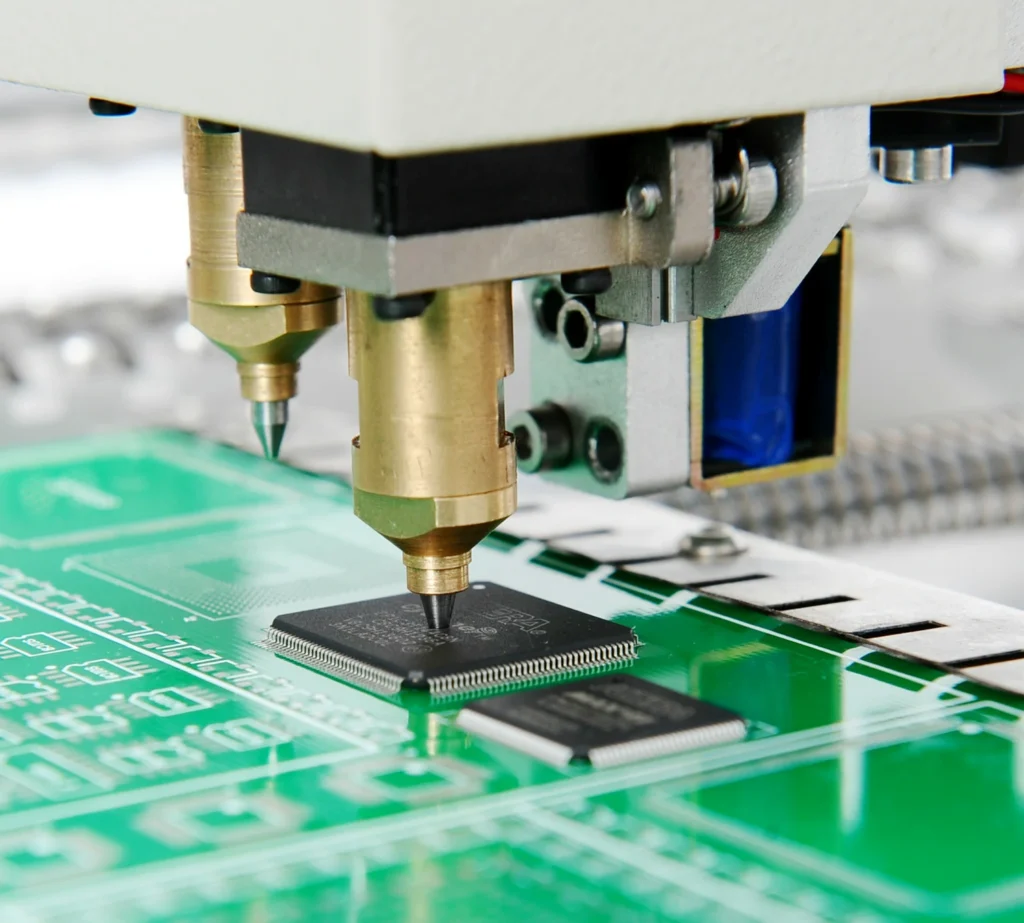

A pick-and-place machine lifts small parts from reels and positions them accurately on solder-paste-laden pads.

The board travels into a reflow oven, gradually heating to fuse solder and form strong component joints.

Automated Optical Inspection (AOI) or X-ray checks every board for solder or component errors.

Final tests, like flying probe or in-circuit checks, guarantee full functionality before shipment.

Where is SMT Used?

SMT’s compact footprint is perfect for smartphones, tablets, and other miniaturized devices.

Wearable medical monitors and diagnostic equipment often rely on lightweight SMT-based designs.

Modern cars contain numerous control units and sensors, which benefit from the space-saving aspects of SMT.

Lower weight is crucial in rockets, aircraft, and defense systems, making SMT a key choice for high-reliability designs.

Best Practices for Successful SMT

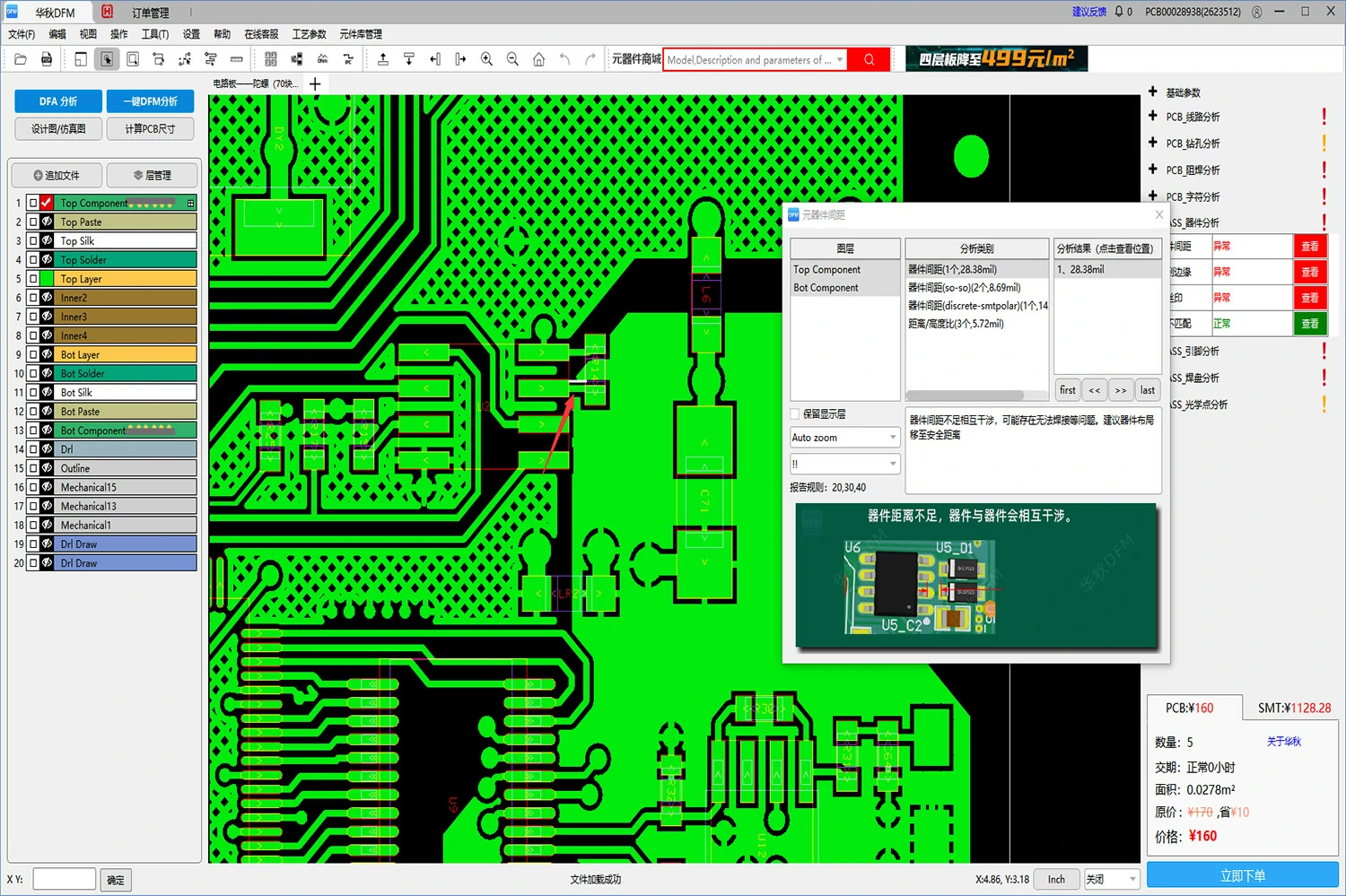

Design for Manufacturing (DFM)

PCBs should be arranged with manufacturing ease in mind, especially around smaller pads and device footprints.

Solder Paste Management

Store solder paste in cool environments and let it reach room temperature before use. Proper mixing helps maintain paste consistency and reliability.

Accurate Placement

Pick-and-place machinery needs correct X-Y data to ensure each device lines up with its matching pad.

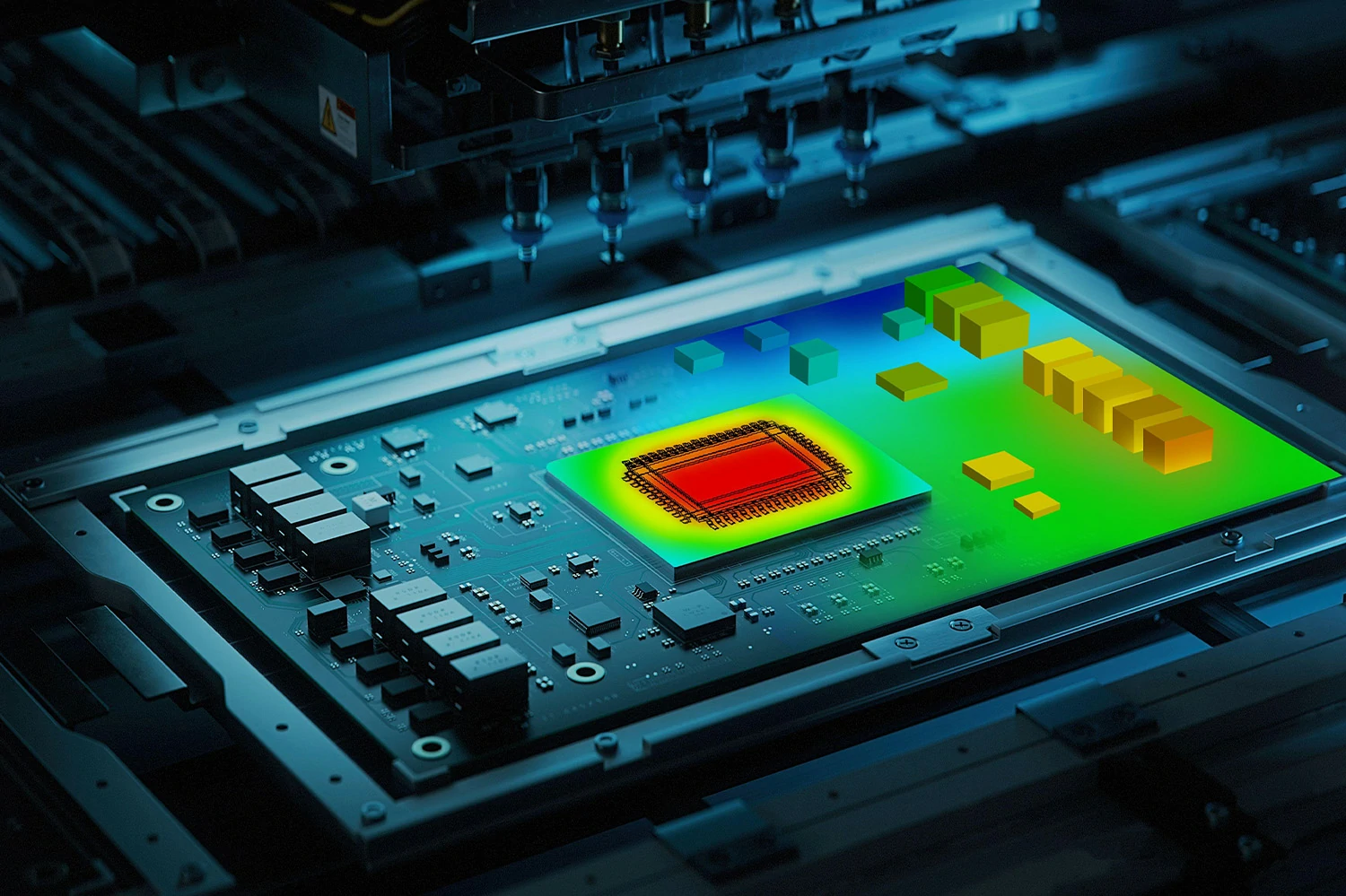

Thermal Profiling

Reflow ovens must follow well-tuned temperature curves to produce solid, defect-free solder joints.

Why SMT Matters in Electronics

By adding more components onto smaller boards, SMT helps push product designs to be lighter and sleeker. This density also lowers noise and signal delays, critical for higher-frequency circuits. In addition, automated assembly trims costs and speeds up production.

Advantages of Surface Mount Technology

Reduced Size & Weight

Tiny parts and shorter leads allow sleek, lightweight boards.

Enhanced Performance

Compact layouts mean fewer parasitic issues, so the boards work more efficiently.

Lower Production Costs

Elimination of drilling and streamlined assembly both cut expenses.

Simplified Assembly

Automation creates consistent, repeatable solder joints at large scale.

How SMT Differs from Traditional THT

THT requires drilling holes for leads, while SMT attaches parts on the board surface. SMT saves space and supports higher component density, but THT leads create stronger mechanical bonds.

Comparing SMT and THT

SMT chips are generally smaller, with shorter leads.

SMT involves solder paste, reflow ovens, and pick-and-place machines; THT needs holes and wave solder.

THT’s lead-through-hole method tolerates more stress, whereas SMT focuses on compactness.

SMT Assembly FAQs

Is SMT Feasible for Prototypes?

What is an SMD?

Can SMT and THT Coexist on One PCB?

How Do SMT and SMD Differ?

Your One-Stop PCB Assembly Partner

Mars PCB is here to turn your concepts into finished products. Let’s bring your designs to life with expert SMT solutions.