Rogers PCBs are high-performance circuit boards utilizing specialized laminate materials from Rogers Corporation, engineered to overcome the significant challenges of radio frequency (RF) and microwave applications. The primary benefits of using Rogers PCBs are their exceptionally low signal loss (low Df), a highly stable dielectric constant (Dk) across a wide range of frequencies and temperatures, and superior thermal management. These characteristics make them the gold standard for high-frequency electronics where the performance of standard FR-4 materials is inadequate, ensuring optimal signal integrity, reliability, and efficiency.

Table of Contents

- What Exactly Are Rogers PCBs and Why Do They Matter in RF Design?

- Unlocking Superior Performance: The Core Benefits of Rogers PCBs

- Unmatched Signal Integrity: The Critical Role of Low Dielectric Loss (Df)

- Precision and Consistency: Why a Stable Dielectric Constant (Dk) is Non-Negotiable

- Reliability Under Pressure: Superior Thermal Management and Conductivity

- Built for Harsh Realities: Low Moisture Absorption and Environmental Stability

- Rogers vs. FR-4: A Head-to-Head Comparison for High-Frequency Applications

- Which Rogers Material is Right for Your RF Application? A Guide to Popular Series

- Real-World Impact: Where Are Rogers PCBs Making a Difference?

- Conclusion: Why Investing in Rogers PCBs is a Strategic Move for Future-Proof RF Design

What Exactly Are Rogers PCBs and Why Do They Matter in RF Design?

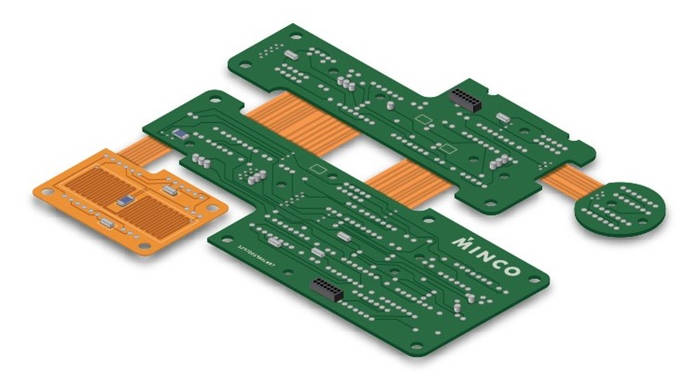

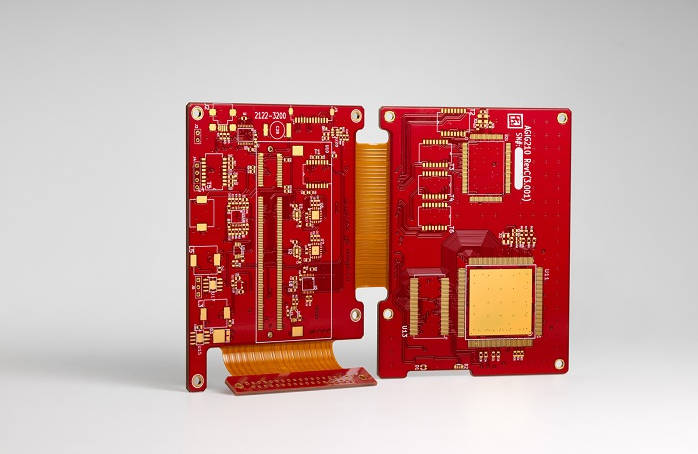

A Rogers PCB is a printed circuit board fabricated using high-frequency laminate materials manufactured by Rogers Corporation. Unlike conventional PCBs that predominantly use FR-4 (Flame Retardant, Level 4) glass-epoxy substrates, Rogers materials are advanced composites, often incorporating ceramic fillers with hydrocarbon or PTFE (Teflon) resins. This unique composition is specifically engineered to provide the electrical and mechanical properties necessary for high-performance RF, microwave, and high-speed digital circuits.

In the world of radio frequency engineering, precision is paramount. As signal frequencies increase into the gigahertz (GHz) range, the physical characteristics of the PCB substrate itself begin to profoundly influence the circuit’s performance. Standard FR-4, while cost-effective and suitable for lower-frequency applications, exhibits significant signal loss, and its dielectric properties can vary unpredictably with changes in frequency, temperature, and humidity. This leads to signal degradation, impedance mismatches, and overall system unreliability. Rogers PCBs directly address these shortcomings, providing a stable and predictable foundation that allows designers to achieve the tight tolerances and high performance their RF applications demand.

Unlocking Superior Performance: The Core Benefits of Rogers PCBs

The decision to specify Rogers material for a PCB design is driven by the need for performance that commodity materials simply cannot deliver. The benefits extend beyond a single metric, creating a synergistic effect that enhances the entire RF system.

Unmatched Signal Integrity: The Critical Role of Low Dielectric Loss (Df)

Perhaps the most celebrated advantage of Rogers materials is their remarkably low dielectric loss, also known as the dissipation factor (Df) or loss tangent. Dielectric loss represents the amount of signal energy absorbed by the PCB substrate and converted into heat as the electromagnetic wave propagates through it. In high-frequency applications, a high Df, typical of FR-4 (around 0.020), leads to significant signal attenuation. This means the signal becomes weaker as it travels across the board, reducing the effective range of a transmitter or the sensitivity of a receiver.

Rogers materials, such as the RO4350B with a Df of approximately 0.0037, exhibit an order of magnitude less loss. This drastic reduction in signal absorption ensures that more of the signal’s power reaches its destination. The practical implications are immense: it allows for longer trace lengths without the need for amplification, improves the signal-to-noise ratio (SNR) for clearer communication, enhances power efficiency by wasting less energy as heat, and is crucial for high-power amplifiers and antenna systems.

Precision and Consistency: Why a Stable Dielectric Constant (Dk) is Non-Negotiable

The dielectric constant (Dk) of a substrate determines the speed at which a signal travels and is a critical parameter for calculating the characteristic impedance of transmission lines on the PCB. For an RF circuit to function correctly, the impedance must be precisely controlled and matched throughout the signal path to prevent reflections and power loss. Any variation in the Dk will alter the impedance, disrupting the circuit’s performance.

Rogers materials are engineered to have an exceptionally stable Dk that remains consistent across a broad spectrum of frequencies and operating temperatures. While the Dk of FR-4 can fluctuate significantly as frequency changes, Rogers laminates like the RO3000 series maintain a tight tolerance. This stability ensures predictable circuit performance, allowing for accurate modeling during the design phase and reliable operation in the field, where temperatures can vary dramatically. This is indispensable for components like filters, couplers, and antennas, whose performance is directly tied to the physical dimensions and the Dk of the substrate.

Reliability Under Pressure: Superior Thermal Management and Conductivity

High-frequency circuits, especially power amplifiers and other active components, can generate substantial amounts of heat. Efficiently dissipating this heat is vital for the component’s reliability and longevity. Rogers PCBs often possess a higher thermal conductivity compared to FR-4. This allows them to more effectively transfer heat away from critical components and spread it across the board or to a heatsink, preventing thermal hotspots and keeping operating temperatures within safe limits.

Furthermore, Rogers materials are designed with a low Coefficient of Thermal Expansion (CTE), particularly in the Z-axis (the thickness of the board). The CTE measures how much a material expands or contracts with changes in temperature. A low Z-axis CTE, closely matched to that of copper, ensures the integrity of plated through-holes (vias) during thermal cycling. This greatly reduces the risk of via barrel cracking or pad lifting, which are common failure points in FR-4 boards used in applications with significant temperature swings, such as aerospace and automotive electronics.

Built for Harsh Realities: Low Moisture Absorption and Environmental Stability

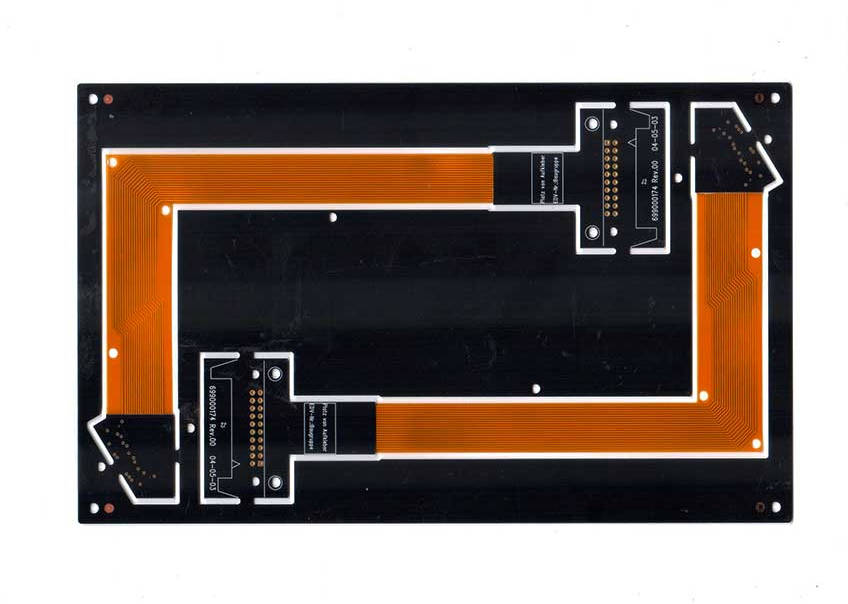

Moisture is an enemy of high-frequency circuits because water has a very high dielectric constant. When a PCB substrate absorbs moisture from the air, its overall Dk and Df can change, leading to performance degradation. Rogers materials are formulated to have extremely low moisture absorption rates. This inherent hydrophobicity ensures that their electrical properties remain stable even when operating in humid or fluctuating environmental conditions. This reliability is essential for outdoor equipment, marine radar systems, and any application where consistent performance is required regardless of the environment.

Rogers vs. FR-4: A Head-to-Head Comparison for High-Frequency Applications

To truly appreciate the advantages of Rogers PCBs, a direct comparison with the industry-standard FR-4 is essential. While FR-4 is an excellent, cost-effective choice for digital and low-frequency analog circuits, its limitations become starkly apparent as frequencies climb into the RF and microwave spectrum.

| Parameter | Rogers Material (e.g., RO4350B) | Standard FR-4 |

|---|---|---|

| Dielectric Constant (Dk) | Very stable, e.g., 3.48 ± 0.05 @ 10 GHz. Consistent across frequencies. | Variable, typically 4.2 to 4.8. Fluctuates significantly with frequency. |

| Dissipation Factor (Df) | Extremely low, e.g., ~0.0037 @ 10 GHz. Minimizes signal loss. | High, typically ~0.020 @ 1 GHz. Causes significant signal attenuation. |

| Thermal Conductivity | Good to excellent (e.g., 0.6-0.8 W/mK). Efficient heat dissipation. | Poor (e.g., 0.25 W/mK). Prone to hotspots. |

| Z-Axis CTE | Low (e.g., ~32 ppm/°C). High via reliability. | High (e.g., ~70+ ppm/°C). Risk of via failure in thermal cycles. |

| Moisture Absorption | Very low (e.g., ~0.06%). Stable performance in humid environments. | Moderate (~0.15% to 0.25%). Properties can drift with humidity. |

| Cost | Higher initial cost, but justified by performance and reliability. | Low cost, ideal for non-critical and low-frequency applications. |

Which Rogers Material is Right for Your RF Application? A Guide to Popular Series

Rogers Corporation offers a wide portfolio of materials, each tailored for different performance requirements and cost targets. Selecting the right one is a key step in the design process.

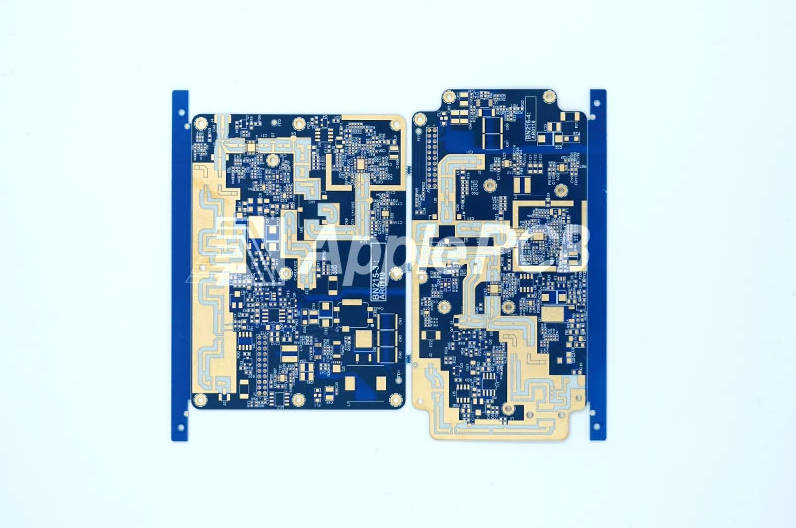

The Industry Workhorse: RO4000® Series (e.g., RO4350B, RO4003C)

The RO4000 series are glass-reinforced hydrocarbon ceramic laminates that offer a superb balance of performance, cost-effectiveness, and ease of fabrication. Materials like RO4350B are extremely popular because they can be processed using standard FR-4 fabrication techniques, which helps to keep manufacturing costs down. They provide excellent high-frequency performance, making them a go-to choice for applications like automotive radar, cellular base station antennas, and power amplifiers.

The Ultimate Performer: RO3000® Series (e.g., RO3003, RO3010)

The RO3000 series are ceramic-filled PTFE composites designed for the most demanding, mission-critical RF and microwave applications. Materials like RO3003 offer some of the most stable Dk and lowest Df values available, maintaining their properties up to millimeter-wave frequencies (e.g., 77 GHz and beyond). Their superior electrical performance makes them ideal for aerospace and defense systems, satellite communications, and high-frequency test and measurement equipment where performance cannot be compromised.

For Extreme Environments: RT/duroid® Series (e.g., RT/duroid 5880)

The RT/duroid series, such as the well-known RT/duroid 5880, are glass-microfiber-reinforced PTFE composites. They are characterized by an extremely low dielectric constant (Dk of 2.2 for 5880) and very low loss. Their key advantage is their exceptional chemical resistance and stability in extreme temperature and humidity conditions, making them a top choice for avionics, satellite antennas, and other applications in harsh operational environments.

Real-World Impact: Where Are Rogers PCBs Making a Difference?

The theoretical benefits of Rogers PCBs translate into tangible advantages across numerous cutting-edge industries:

- 5G and Telecommunications: In 5G base stations and user equipment, Rogers materials are essential for massive MIMO antenna arrays, power amplifiers, and millimeter-wave transceivers, enabling higher data rates and lower latency.

- Automotive: Advanced Driver-Assistance Systems (ADAS) rely on 77 GHz automotive radar for collision avoidance and adaptive cruise control. Rogers PCBs ensure the accuracy and reliability of these safety-critical sensors.

- Aerospace and Defense: From phased-array radar systems to satellite communication links and electronic warfare equipment, the reliability and performance of Rogers materials are indispensable.

- IoT and High-Speed Digital: In high-data-rate applications, such as network servers and high-speed test equipment, Rogers laminates are used to ensure signal integrity for data transmission in the tens of Gbps.

Conclusion: Why Investing in Rogers PCBs is a Strategic Move for Future-Proof RF Design

While the initial material cost of a Rogers PCB is higher than that of an FR-4 board, viewing it as a mere expense is a mistake. For any serious RF application, choosing a high-performance substrate is a strategic investment in reliability, performance, and long-term viability. The benefits of using Rogers PCBs—superior signal integrity, stable impedance control, robust thermal management, and environmental resilience—are not just incremental improvements; they are enabling factors for modern high-frequency technology.

By preventing signal degradation, ensuring predictable performance, and enhancing system-level reliability, Rogers PCBs reduce the risk of costly redesigns, improve time-to-market, and deliver a final product that performs as intended in the real world. As frequencies continue to rise and performance demands become even more stringent, the role of advanced materials like those from Rogers will only become more critical, solidifying their position as the essential foundation for the future of RF engineering.

Rogers PCBs, RF applications, benefits of Rogers PCBs, Rogers material, high-frequency PCB, Rogers vs FR-4, low loss PCB material, stable dielectric constant, RF PCB design, Rogers RO4350B, what are Rogers PCBs, high-frequency laminates, RF signal integrity, microwave circuit boards, Rogers PCB for 5G, choosing Rogers material