For high-heat applications, an aluminum PCB is the superior choice over a standard FR4 board due to its exceptional thermal conductivity. Unlike FR4, which is a thermal insulator, aluminum core PCBs are designed to efficiently dissipate heat away from critical electronic components. This direct heat transfer mechanism prevents overheating, significantly enhances component performance and reliability, and extends the overall lifespan of the device, making it the definitive solution for thermally demanding environments like high-power LEDs, power supplies, and automotive electronics.

Table of Contents

- The Core Challenge: Why is Heat a Problem in Modern Electronics?

- Understanding the Contenders: A Deep Dive into FR4 and Aluminum PCBs

- The Head-to-Head Showdown: Aluminum PCB vs. FR4 for Thermal Performance

- When Should You Choose an Aluminum PCB? Key Applications and Use Cases

- Is FR4 Obsolete? When FR4 is Still the Right Choice

- Conclusion: Making the Right Choice for Your High-Heat Application

The Core Challenge: Why is Heat a Problem in Modern Electronics?

As electronic devices become more powerful and compact, the challenge of managing heat becomes increasingly critical. Every electronic component generates heat as a byproduct of its operation. When this heat is not effectively removed, the internal temperature of the components rises, leading to a cascade of negative effects. Elevated temperatures can drastically reduce the lifespan of components like processors and LEDs, cause performance throttling, signal integrity issues, and, in worst-case scenarios, lead to catastrophic system failure. Therefore, effective thermal management is not just an optional feature; it is a fundamental requirement for designing reliable and long-lasting electronics.

Traditional printed circuit boards (PCBs) are often the bottleneck in the thermal path. The standard material, FR4, is an excellent electrical insulator but, unfortunately, also a very poor thermal conductor. This means it traps heat around the components that generate it most. Engineers have historically relied on external solutions like heat sinks, fans, and thermal vias to mitigate this issue, but these add complexity, cost, and bulk to the design. The quest for a more integrated and efficient solution leads directly to the PCB substrate itself, questioning whether the standard material is always the right tool for the job.

Understanding the Contenders: A Deep Dive into FR4 and Aluminum PCBs

To understand why one is better than the other for high-heat applications, we must first understand the fundamental structure and properties of each material. They serve the same basic purpose—providing mechanical support and electrical connections—but their construction leads to vastly different thermal performance characteristics.

What is an FR4 PCB? The Industry Standard Explained

FR4 (Flame Retardant 4) is the most common material used for PCBs. It is a composite material made of woven fiberglass cloth impregnated with an epoxy resin binder. This composition makes it strong, lightweight, and an excellent electrical insulator with high dielectric strength. Its widespread adoption is driven by its low cost and well-understood manufacturing processes, making it the default choice for a vast range of consumer and industrial electronics.

However, its greatest strength in electrical insulation is its greatest weakness in thermal management. The fiberglass and epoxy that prevent electrical current from leaking are also highly effective at trapping heat. The typical thermal conductivity of FR4 is extremely low, usually around 0.3 to 0.5 W/mK (Watts per meter-Kelvin). For low-power applications, this is perfectly acceptable. But when dealing with high-power components, this insulating property causes heat to concentrate in “hot spots,” directly leading to the performance and reliability issues mentioned earlier.

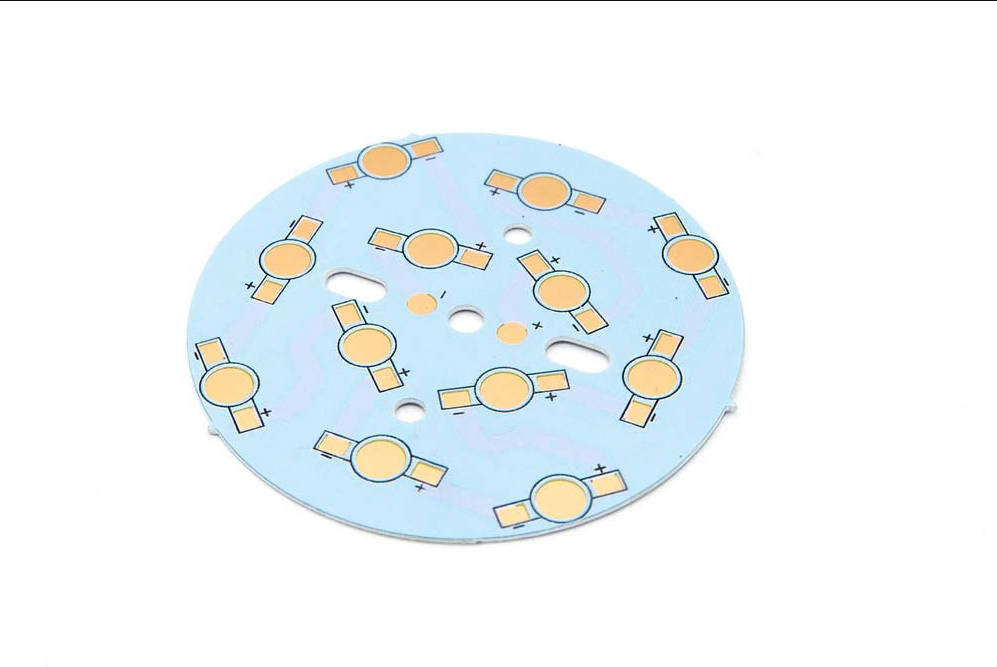

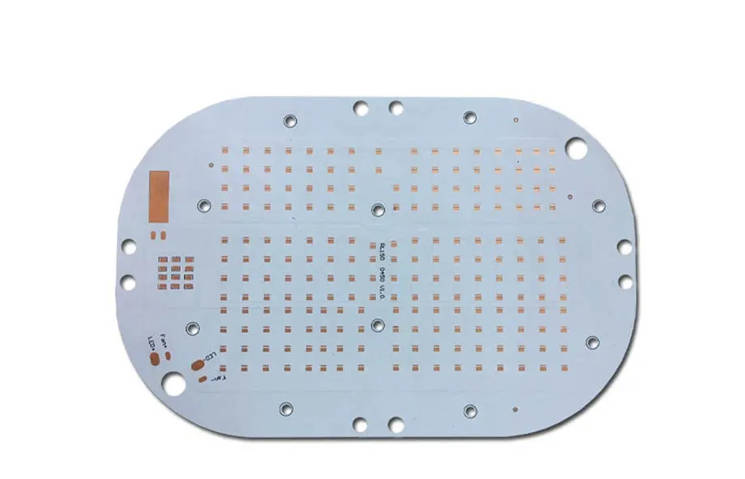

What is an Aluminum PCB? The Thermal Specialist

An Aluminum PCB, also known as a Metal Core PCB (MCPCB) or Insulated Metal Substrate (IMS), is constructed very differently. It consists of a three-layer structure:

- A Copper Circuit Layer: The top layer, identical to a standard PCB, where components are mounted.

- A Dielectric Layer: A very thin, thermally conductive but electrically insulating layer that bonds the copper layer to the aluminum base. This layer is the key to the MCPCB’s performance.

- An Aluminum Base Layer: A thick base of aluminum that acts as a built-in heat sink, providing mechanical rigidity and superior heat dissipation.

This unique construction is designed for one primary purpose: thermal management. The aluminum base has a thermal conductivity of around 200-240 W/mK, hundreds of times higher than FR4. The thin dielectric layer is engineered to have the lowest possible thermal resistance, allowing heat to flow efficiently from the components on the copper layer directly into the aluminum base, where it can be spread over a large surface area and dissipated into the environment. This integrated heat-spreading capability is what makes aluminum PCBs the specialists for high-heat applications.

The Head-to-Head Showdown: Aluminum PCB vs. FR4 for Thermal Performance

When directly compared, the differences between Aluminum and FR4 PCBs become starkly clear, especially in the context of thermally demanding applications. The choice between them often comes down to balancing performance requirements against project costs.

| Feature | Aluminum PCB | FR4 PCB |

|---|---|---|

| Thermal Conductivity | High (Typically 1.0 – 7.0 W/mK for the whole structure, with the aluminum core at ~220 W/mK) | Very Low (Typically 0.3 – 0.5 W/mK) |

| Heat Dissipation | Excellent; acts as a built-in heat sink, spreads heat efficiently. | Poor; traps heat, creating hot spots. Requires external heat sinks. |

| Mechanical Strength | Very High; resistant to breakage and physical stress. | Good, but can be brittle and prone to fracture. |

| Coefficient of Thermal Expansion (CTE) | Lower and more stable, better for surface-mounted components. | Higher, can cause stress on solder joints during thermal cycling. |

| Cost | Higher initial cost. | Low cost, industry standard. |

| Primary Application | High-power LEDs, power supplies, automotive, motor drivers. | General-purpose electronics, low-power devices, prototypes. |

Thermal Conductivity: The Decisive Factor

The single most important metric in this comparison is thermal conductivity. As the table shows, the difference is not just minor; it’s an order of magnitude. An FR4 PCB actively resists the flow of heat, while an aluminum PCB actively encourages it. Imagine trying to cool a hot pan by placing it on a wooden block (FR4) versus a thick metal plate (aluminum). The metal plate will draw heat out of the pan much faster. This is precisely what an aluminum PCB does for your electronic components, pulling damaging thermal energy away from the delicate silicon junctions and spreading it out where it can safely dissipate.

Heat Dissipation and Spreading: How Do They Differ?

The practical effect of high thermal conductivity is superior heat dissipation. On an FR4 board, heat from a component like a power transistor creates a concentrated hot spot. This localized heat has nowhere to go but to build up, increasing the component’s temperature. On an aluminum PCB, that same heat rapidly transfers through the thin dielectric layer into the aluminum core. The aluminum, being an excellent conductor, spreads this thermal energy evenly across the entire board. This prevents the formation of damaging hot spots and significantly lowers the peak operating temperature of the component, often by 10-30°C or more compared to an identical layout on FR4.

Durability and Mechanical Stability Under Thermal Stress

Beyond thermal performance, aluminum offers significant mechanical advantages. Aluminum is a far more robust material than the fiberglass composite of FR4. It is less prone to breaking or cracking during manufacturing, assembly, or due to accidental impacts. Furthermore, its Coefficient of Thermal Expansion (CTE) is lower and more stable than FR4’s. This means that as the board heats up and cools down, the aluminum expands and contracts less, putting less mechanical stress on the solder joints of surface-mounted components. This improved stability is crucial for devices that undergo frequent thermal cycling, such as automotive lighting, leading to a much lower rate of field failures.

Cost vs. Total Cost of Ownership: An Important Distinction

There is no denying that the initial procurement cost of an aluminum PCB is higher than that of an FR4 board. The specialized materials and manufacturing processes contribute to this price difference. However, it is critical to consider the total cost of ownership. By using an aluminum PCB, you may be able to eliminate the need for separate heat sinks, cooling fans, thermal interface materials, and the associated assembly labor. This can significantly reduce the bill of materials (BOM) and complexity of the final product. More importantly, the enhanced reliability and longer lifespan of the components lead to fewer warranty claims and a better brand reputation, a financial benefit that often far outweighs the initial higher cost of the board.

When Should You Choose an Aluminum PCB? Key Applications and Use Cases

The decision to use an aluminum PCB becomes clear when the application involves significant heat generation. Any design where component temperature is a limiting factor for performance or reliability is a prime candidate for an aluminum substrate. Key examples include:

- LED Lighting: This is the most common application. High-power LEDs are notoriously inefficient, converting a large portion of electricity into heat. Aluminum PCBs are essential for drawing this heat away from the LED chip, preventing color shift, reduced brightness, and premature failure. You will find them in streetlights, automotive headlights, and high-power architectural lighting.

- Power Electronics: Power supplies, converters, inverters, and solid-state relays all feature components like MOSFETs and regulators that handle large amounts of current and generate substantial heat. Aluminum PCBs provide a stable and cool operating environment for these components.

- Automotive Industry: From engine control units (ECUs) to power steering systems and headlight assemblies, automotive electronics operate in harsh, high-temperature environments and demand extreme reliability. Aluminum PCBs provide the necessary thermal and mechanical robustness.

- Motor Drivers: The electronics used to control electric motors must manage high currents and the resulting heat. Aluminum PCBs are critical for ensuring these drivers operate reliably without overheating.

Is FR4 Obsolete? When FR4 is Still the Right Choice

Despite the clear thermal advantages of aluminum, FR4 is far from obsolete. It remains the ideal choice for the vast majority of electronic applications where heat is not a primary design concern. For low-power digital logic, microcontrollers, sensor circuits, and general consumer electronics, the thermal performance of FR4 is more than adequate. Its low cost, ease of manufacturing for complex multi-layer designs, and excellent electrical properties make it the most practical and cost-effective solution for these applications. The key is to recognize when a design crosses the thermal threshold where the limitations of FR4 become a liability.

Conclusion: Making the Right Choice for Your High-Heat Application

In the contest between Aluminum PCB and FR4 for high-heat applications, the winner is clear. While FR4 remains the workhorse of the electronics industry for general-purpose use, it fundamentally fails as a thermal management solution. For any design where heat compromises performance, reliability, or lifespan, an aluminum PCB is not a luxury—it is an engineering necessity. Its ability to efficiently conduct and dissipate heat provides a more integrated, reliable, and often more cost-effective solution in the long run than an FR4 board burdened with external cooling hardware. By understanding the profound difference in thermal conductivity, engineers can make an informed decision, choosing the right material to ensure their product performs flawlessly under pressure.

Aluminum PCB, FR4, High-Heat Applications, Thermal Management, Metal Core PCB, Aluminum PCB vs FR4, Heat Dissipation, Thermal Conductivity, FR4 temperature limit, MCPCB, Insulated Metal Substrate, PCB thermal solutions